12

Adjustments

Disconnect machine from

power source before making adjustments.

Tools required for adjustments:

8mm & 12mm wrenches

4mm hex wrench

machinist's protractor or adjustable square

steel straight edge

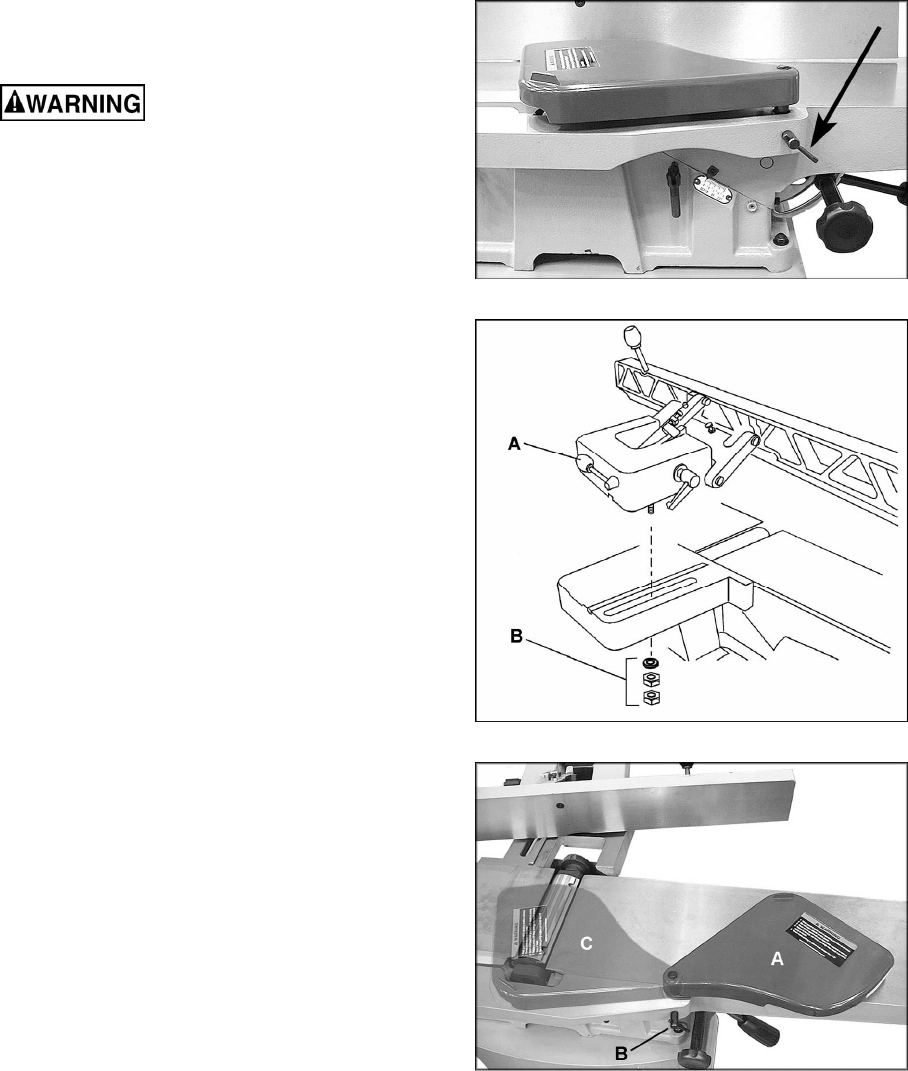

Cutter Guard

Removing Guard:

Some adjusting procedures, as well as

rabbeting operations, will require removal of the

guard. Simply loosen handle on rabbeting ledge

(Figure 12) and vertically lift guard out of the

hole.

Mounting Guard:

The guard is spring tensioned. When mounted,

it must have enough tension to completely cover

the cutterhead, and press firmly against the

fence. To adjust the guard tension:

1. Disconnect machine from power source.

2. Release the fence locking handle (A, Figure

13) and remove the two hex nuts and

washer (B, Figure 13) which hold the fence

to the fence support. Lift up the fence

assembly and set it out of the way of the

cutter guard.

3. Rotate the cutter guard (A, Figure 13) to the

right and set it into its hole as shown. Firmly

tighten the handle (B, Figure 13). The

farther to the right you set the guard, the

stronger tension it will have.

4. Rotate the guard counterclockwise (C,

Figure 14) until it covers the cutterhead.

NOTE: Keep hands away from knives!

Hold it in this position (using an assistant or

block of wood) and re-mount the fence.

5. Test the tension by swinging the guard

away from the fence and then releasing it.

The guard should snap back to the fence.

NOTE: The guard must operate freely and must

not drag on the rabbeting ledge or infeed table.

If dragging occurs, check that the handle (Figure

12) is tight. If guard still drags, the guard

assembly may need to be replaced.

Figure 12

Figure 13

Figure 14