9

3. The stand can be secured to the floor using

two anchor bolts (not provided) through the

holes inside the bottom of the stand.

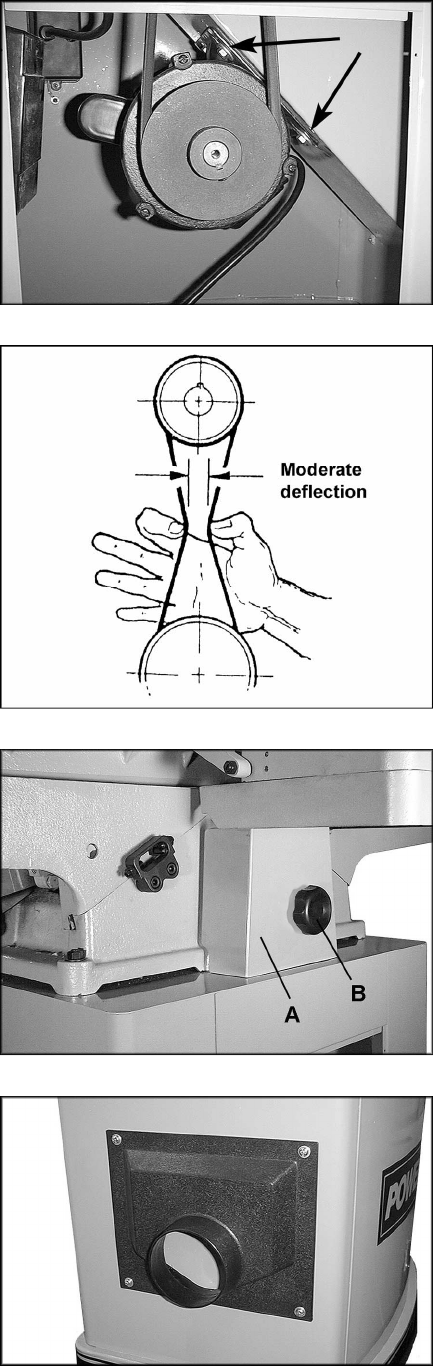

Aligning Pulleys

Place a straight edge against the motor pulley

and cutterhead pulley to make sure they are

aligned. If adjustment is necessary, loosen the

set screws in the motor pulley, and slide it as

needed until alignment is achieved. Re-tighten

set screws.

Mounting Drive Belt

1. Place the belt into the groove of the

cutterhead pulley.

2. Reach through the dust chute opening in the

side of the stand with a 12mm wrench, and

loosen the nuts on the motor mount screws

(Figure 6).

3. Lift up on the motor to provide slack, and

place the lower end of the drive belt into the

motor pulley groove.

4. Let the motor slide down and push down on

it until the belt is properly tensioned. NOTE:

There should be only moderate deflection in

the belt midway between the pulleys when

using light finger pressure (Figure 7).

5. Tighten the four hex nuts on the motor

mount screws.

Mounting Pulley Guard

Place the pulley guard (A, Figure 8) as shown,

and secure with knob (B, Figure 8).

Mounting Dust Chute

It is strongly recommended that a dust collection

system (not provided) be connected to the

jointer. It will help keep your shop clean, and

reduce the risk of health problems due to wood

dust. The dust collector should have sufficient

capacity for this size jointer.

Place the dust chute over the opening in the

jointer stand, and secure with four 1/4-20 x 1/2

pan head screws and four 1/4 flat washers

(Figure 9)

Connect a dust collection hose to the dust chute

on the jointer and secure it with a hose clamp or

duct tape. NOTE: Dryer vent hose is not

acceptable for this purpose.

Figure 6

Figure 7

Figure 8

Figure 9