11

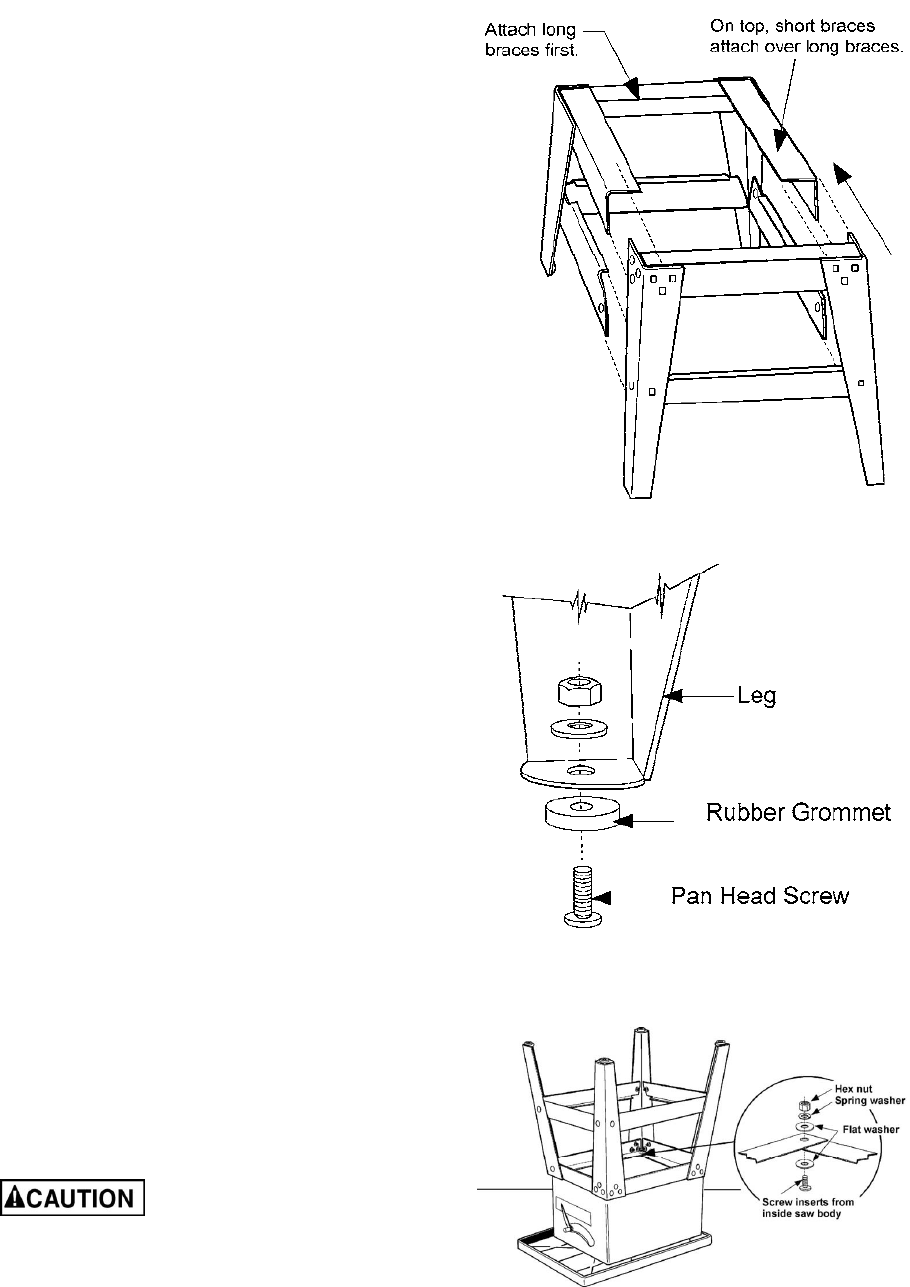

2. Attach the four short braces to one set of

legs as shown in Figure 6.

3. Complete the stand assembly by attaching

the other set of legs as shown in Figure 7.

4. To attach rubber feet to each leg, first use a

cross-point screwdriver and screw the 1/4-

20 x 1 pan head screw through the recessed

hole of the rubber grommet as shown in

Figure 8. Push the screw through the hole

provided at the bottom of each leg, and

tightly fasten down with 1/4 flat washer and

1/4 hex nut.

5. Remember, leave all other stand assembly

nuts only finger tight!

Mounting Saw to Stand

Tip: Remove all contents from carton except

saw and one extension wing. Put some soft

padding on floor beside box. Fold back carton

flaps and gently roll carton upside down on to

padding. Lift off carton, being careful not to let

extension wing fall.

1. Place table top upside down with its surface

on a flat floor, and place stand, with legs

upside down, atop the cabinet. See Figure 9

2. Align the holes of stand with holes on

bottom flange of saw base and tightly

secure with four 5/16-18 x 1 hex head

screws, four 5/16 hex nuts, four 5/16 flat

washers, and four 5/16 spring washers. The

screw heads should be inside of the saw

body (see inset, Figure 9).

3. Carefully raise the machine to its upright

position.

4. With the saw located at the place of

operation, (with a solid foundation), spread

the stand legs to self-align the machine. (If

using an optional mobile base, place the

machine onto the base now). When all four

legs are seated solidly on the floor (or

mobile base), tighten down securely all nuts

and screws in the stand assembly.

NOTE: If the saw is to be used without the

metal stand provided, care must be taken to

provide a hole in the stand or bench used by the

operator to facilitate the removal of sawdust.

If there is any tendency to

slide, walk, or tip over during operation, the

stand or bench MUST be secured to the

floor.

Figure 7

Figure 8

Figure 9