21

• Check the operation of the anti-kickback

pawls before starting a cut. If the pawls do

not stop the reverse motion of a workpiece,

resharpen all the points.

• Keep your face and body out of line with

potential kickbacks when possible, including

when starting or stopping the machine.

3. Dull or improperly sharpened blades and

blades with gum or resin adhering to them

may cause an accident with the tilting arbor

saw. Never use a cracked saw blade. The

use of a sharp, well maintained, and correct

cutting tool for the operation will help avoid

kickbacks.

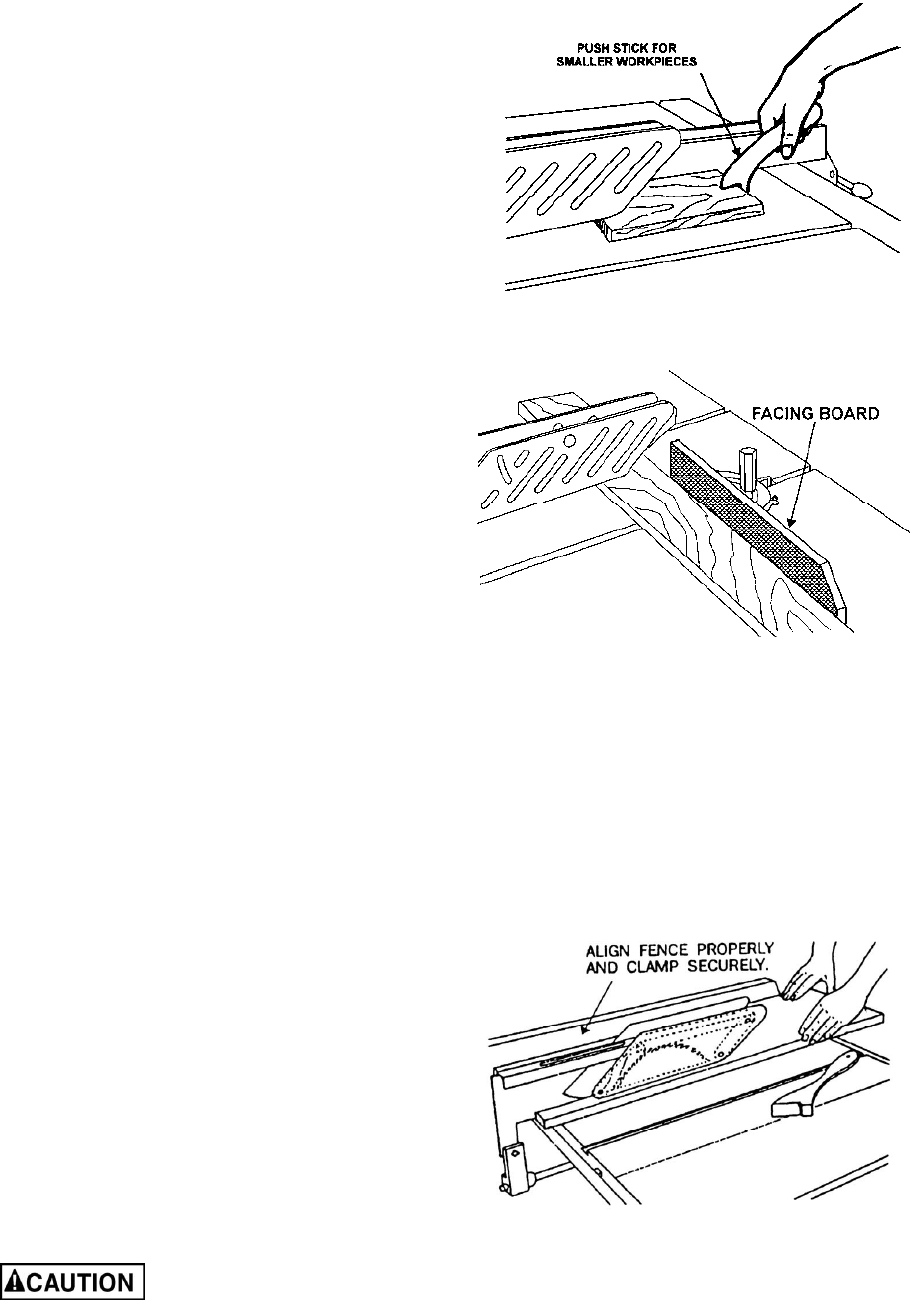

4. Support the work properly and hold it firmly

against the gauge or fence. Use a push stick

or push block when ripping short, narrow (6"

width or less), or thin work. Use a push

block or miter gauge hold-down when

dadoing or molding. (Figure 36)

5. For added safety in crosscutting use an

auxiliary wood facing attached to the miter

gauge using the holes provided. (Figure 37)

6. Never use the fence as a length stop when

crosscutting. Do not hold on to or touch the

free end or cutoff section of a workpiece. On

through-sawing operations, the cut-off

section must not be confined.

7. Always keep your hands out of line with the

saw blade and never reach past the rotating

blade with either hand to hold down the

workpiece.

8. Use the miter gauge on the left hand side of

the saw blade when doing miter or

compound miter cuts to provide more hand

clearance and safety.

Operating Procedures

Ripping

1. Ripping is a sawing process where the

workpiece is fed with the grain into the saw

blade using the fence both as a guide and a

positioning device to ensure the desired

width of cut (Figure 38).

2. Many manufacturers make blades

specifically designed for this operation.

Before starting a ripping cut,

be sure the fence is clamped securely and

properly aligned.

Figure 36

Figure 37

Figure 38