9

Assembly and Installation

Tools needed for assembly:

5mm hex wrench

12mm and 14mm open end wrenches

Remove the clear plastic from around the feeder

and stand.

Exposed metal surfaces have been given a

protective coating at the factory. This should be

removed with a soft cloth moistened with a good

commercial solvent, such as kerosene or

mineral spirits. Do not use acetone, gasoline, or

lacquer thinner for this purpose. Do not get

solvents near plastic or rubber parts, and do not

use an abrasive pad because it may scratch

metal surfaces.

The Stock Feeder should be mounted to an

auxiliary machine in a well-lit area. Leave

enough space around the work area for loading

and off-loading stock and general maintenance.

The stock feeder and the

auxiliary machine to which you are mounting

it should both be disconnected from power

during installation.

1. Determine the mounting location for the

stand. Keep in mind the overall length of the

horizontal arm on the stand (27-1/2”) so that

there will be enough adjustment when the

Stock Feeder is mounted.

IMPORTANT: Locate the stand so that you

will not drill through any ribs or supports

beneath the table surface.

2. Use the provided boring template to find the

centerline spacing for the holes in the

feeder’s base. Clean the mounting surface,

then remove the backing from the boring

template and stick the template carefully

into place on the mounting surface.

NOTE: The same template can be found on

page 25.

3. Center punch and drill four 8.5 millimeter

diameter holes in the surface, then tap the

holes with M10 x P1.5 threads. Alternatively,

if you plan to secure the stand with hex nuts

from below the mounting surface, drill

clearance holes of 7/16” diameter without

tapping.

4. Peel off the boring template and discard.

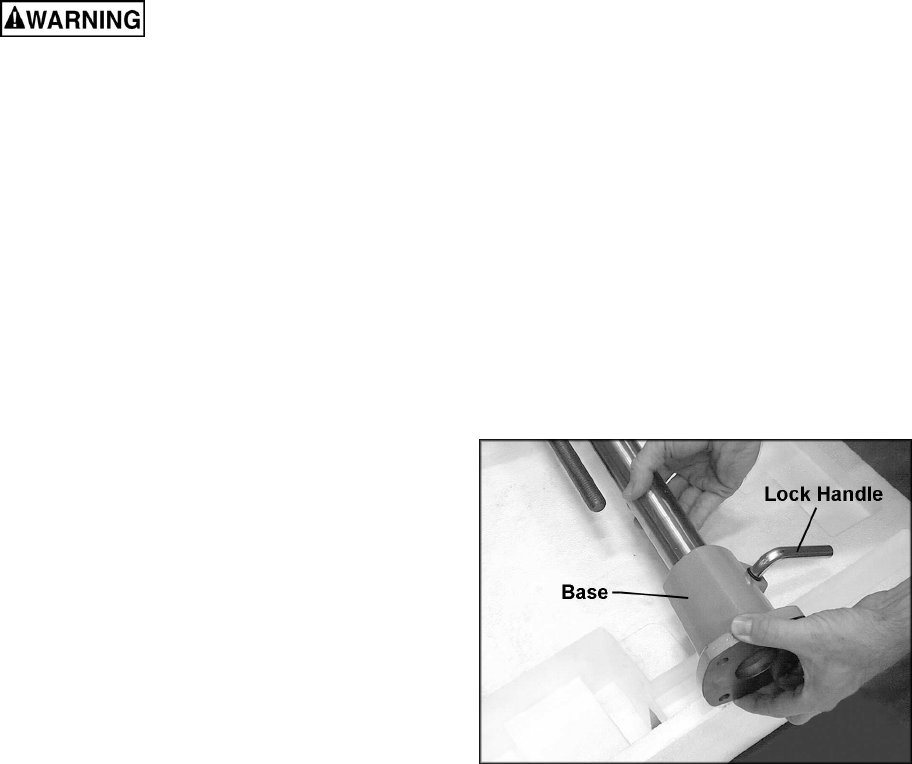

5. Loosen the lock handle and remove the

base from the stand assembly, shown in

Figure 1.

Figure 1