Page 16

MAINTENANCE

■ Securely retighten the hex head bolts.

■ Depress the cutter block lock button and rotate the cutter

block 180°.

■ Repeat the above steps for the second blade.

■ Place the safety cover on the cutter head assembly

leaving the socket head screws loose.

■ Reinstall the dust chute by slipping it under the socket

head screws and lock washers (see page 9).

■ Tighten socket head screws securely.

Note: Cutter blades require only slight adjustments to

offset planing imperfections.

LUBRICATION

Periodically, check all moving parts (spindle, roller surfaces,

handles, etc.) to ensure they are clean and well lubricated.

A light film of oil wiped on the face of the cutter blades will

keep them rust-free. All of the bearings in this tool are

lubricated with a sufficient amount of high grade lubricant for

the life of the unit under normal operating conditions. No

further lubrication is required.

MOTOR/ELECTRICAL

The universal motor is easy to maintain but must be kept

clean. Do not allow water, oil or sawdust to accumulate on or

in it. The sealed bearings are permanently lubricated and

need no further attention.

BRUSH REPLACEMENT

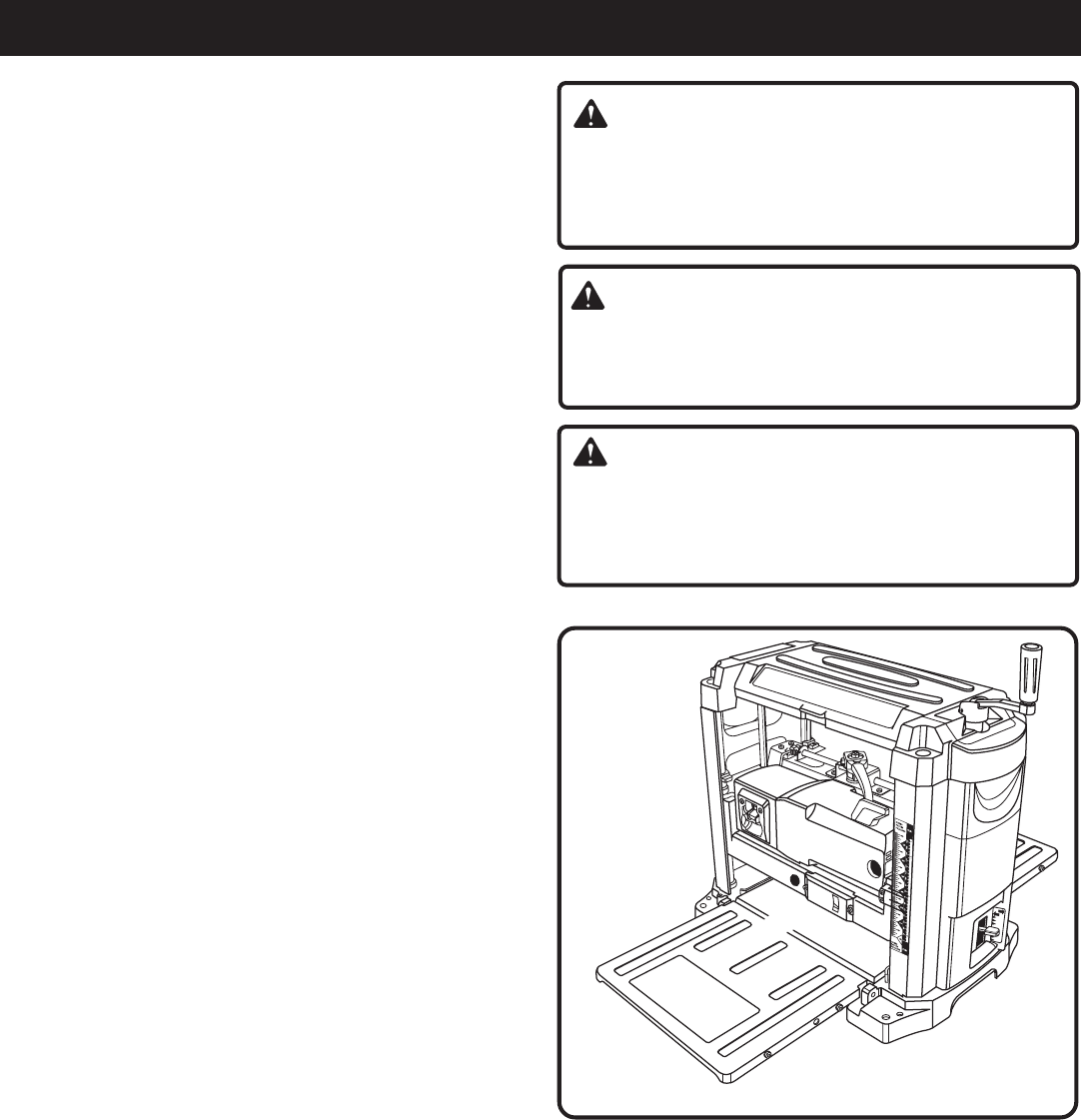

See Figure 16.

Your planer has externally accessible brush assemblies that

should be checked every 10 to 15 operating hours for wear.

To inspect or replace these brushes, unscrew the brush cap

located at the right front and left rear of the planer. Be sure

to replace the brush cap securely after inspection or repairs.

CLEANING

Sawdust buildup and other debris can cause the tool to plane

inaccurately. Periodic cleaning and waxing is needed for

accurate, precision planing.

Do not allow sawdust to accumulate on the planer. Clean the

dust chute after each use. Moving parts should be cleaned

regularly with penetrating oil and lubricated with a light

coating of medium-weight machine oil.

Paste wax should be applied to the planing table surface to

ease the movement of workpieces across it. Paste wax can

also be used on infeed and outfeed support surfaces but be

careful not to use so much that it will be absorbed into the

wood and interfere with staining.

Check feed rollers after each use for resin buildup because

they must be clean to be effective. If buildup occurs, use a

mild, nonflammable tar and pitch remover.

Fig. 16

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing dust.

If operation is dusty, also wear a dust mask.

WARNING:

To ensure safety and reliability, all repairs should be

performed by a qualified service technician at a Ryobi

Authorized Service Center to avoid risk of personal

injury.

BRUSH CAP

BRUSH