Page 12

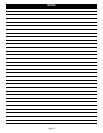

SETTING THE TABLE FOR HORIZONTAL OR

BEVEL CUTTING

See Figure 8.

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw from the power source could result in

accidental starting causing possible serious injury.

A bevel scale is located under the saw table as a convenient

guide for setting the approximate saw table angle for bevel

cutting. When greater precision is required, make practice

cuts on scrap material and adjust the saw table as necessary

for your requirements.

Note: When cutting at angles, the drop foot should be tilted

so it is parallel to the saw table and rests flat against the

workpiece. To tilt the drop foot, loosen phillips screw, tilt drop

foot to the proper angle, then retighten screw.

ADJUSTMENTS

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw from the power source could result in

accidental starting causing possible serious injury.

ADJUSTING DROP FOOT

■ Loosen the drop foot lock knob.

See Figure 4, page 9.

■ Center the drop foot around the saw blade to the desired

position.

■ Tighten the drop foot lock knob.

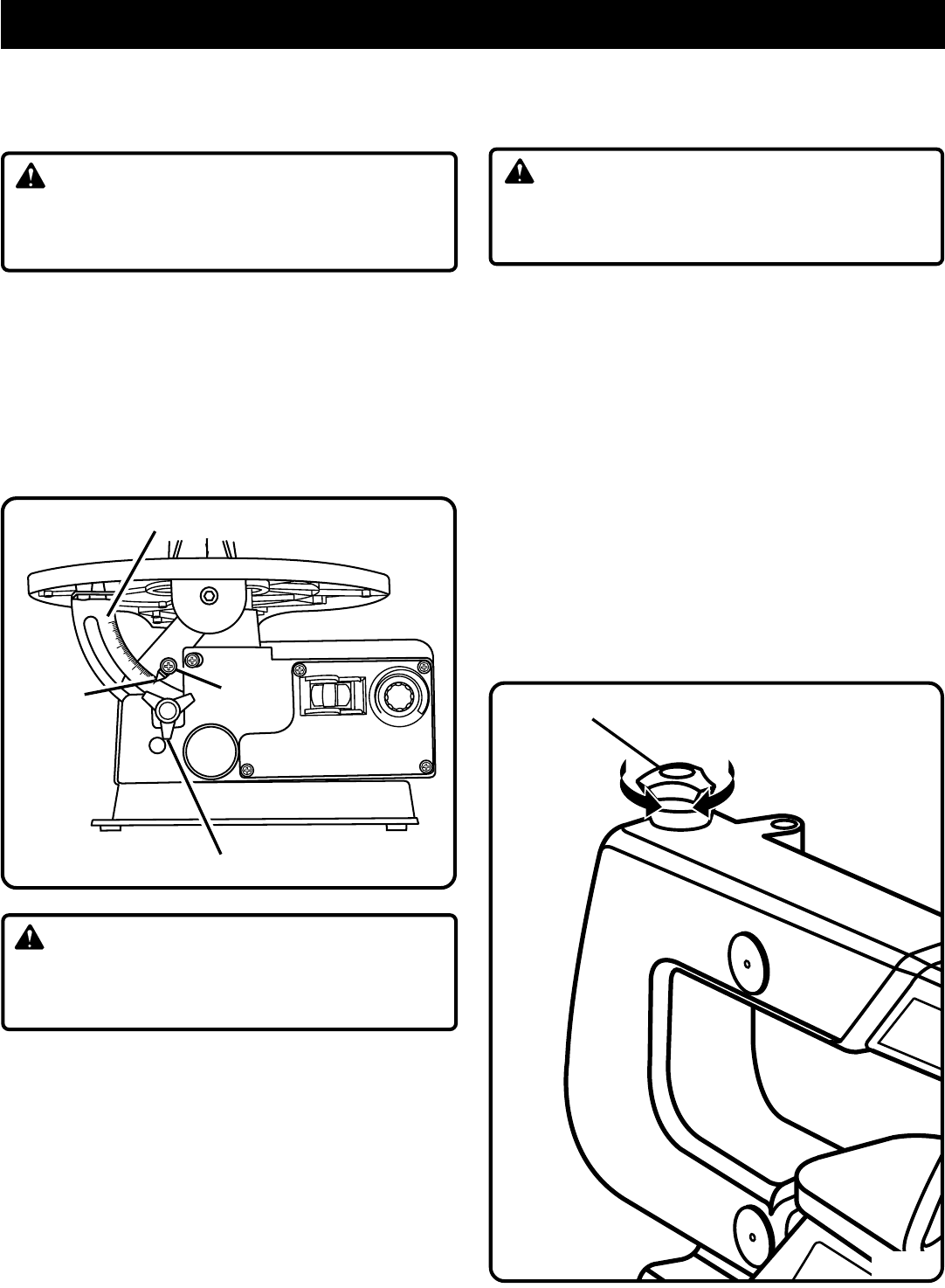

ADJUSTING BLADE TENSION

See Figure 9.

■ Turn off and unplug the saw from the power source.

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw from the power source could result in

accidental starting causing possible serious injury.

■ Turning the blade tension knob counter-

clockwise decreases (or loosens) blade tension.

■ Turning the blade tension knob clockwise increases (or

tightens) blade tension.

Note: Adjustments to blade tension can be made at any time.

Check tension by the sound the blade makes when plucked

like a guitar string. This method of adding tension to the blade

can be developed with practice and requires knowing your

scroll saw.

■ Pluck the back straight edge of blade while turning

tension adjusting knob. Sound should be a musical note.

Sound becomes less flat as tension increases. Sound

decreases with too much tension.

Note: Be careful not to adjust blade too tight. Too much

tension may cause the blade to break as soon as you start

cutting. Too little tension may cause the blade to bend or

break before the teeth wear out.

TO

RELEASE

45

30

15

0

O

N

O

F

F

Fig. 8

TABLE LOCK KNOB

BEVEL SCALE

SCALE

INDICATOR

SCREW

TO

ENGAGE

BLADE TENSION KNOB

Fig. 9