Page 17

WARNING:

When servicing, use only identical Ryobi replacement

parts. Use of any other part may create a hazard or cause

product damage.

GENERAL MAINTENANCE

■ Keep your scroll saw clean.

■ After cleaning the table top initially, apply a thin coat of

automobile type (paste) wax to the table top so the wood

slides easily while cutting.

■ Do not allow pitch to accumulate on the saw table. Clean

with gum and pitch remover.

ARM BEARINGS

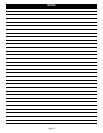

See Figure 15.

Lubricate the arm bearings after the first 10 hours of use. Oil

after every 50 hours of use or whenever there is a squeak

coming from the bearings.

■ Carefully place the saw on its side as shown in

Figure 15.

Remove the rubber cap from the upper and the lower arm

of the saw.

■ Squirt a few drops of SAE20 oil around the shaft end and

arm bearings. Let oil soak in overnight, remaining in this

position.

Note: Lubricate the bearings on the other side of the saw in

this same manner.

WARNING:

If the power cord is worn, cut, or damaged in any way,

have it replaced immediately by a qualified service

technician. Failure to do so could result in serious personal

injury.

MOTOR BRUSHES

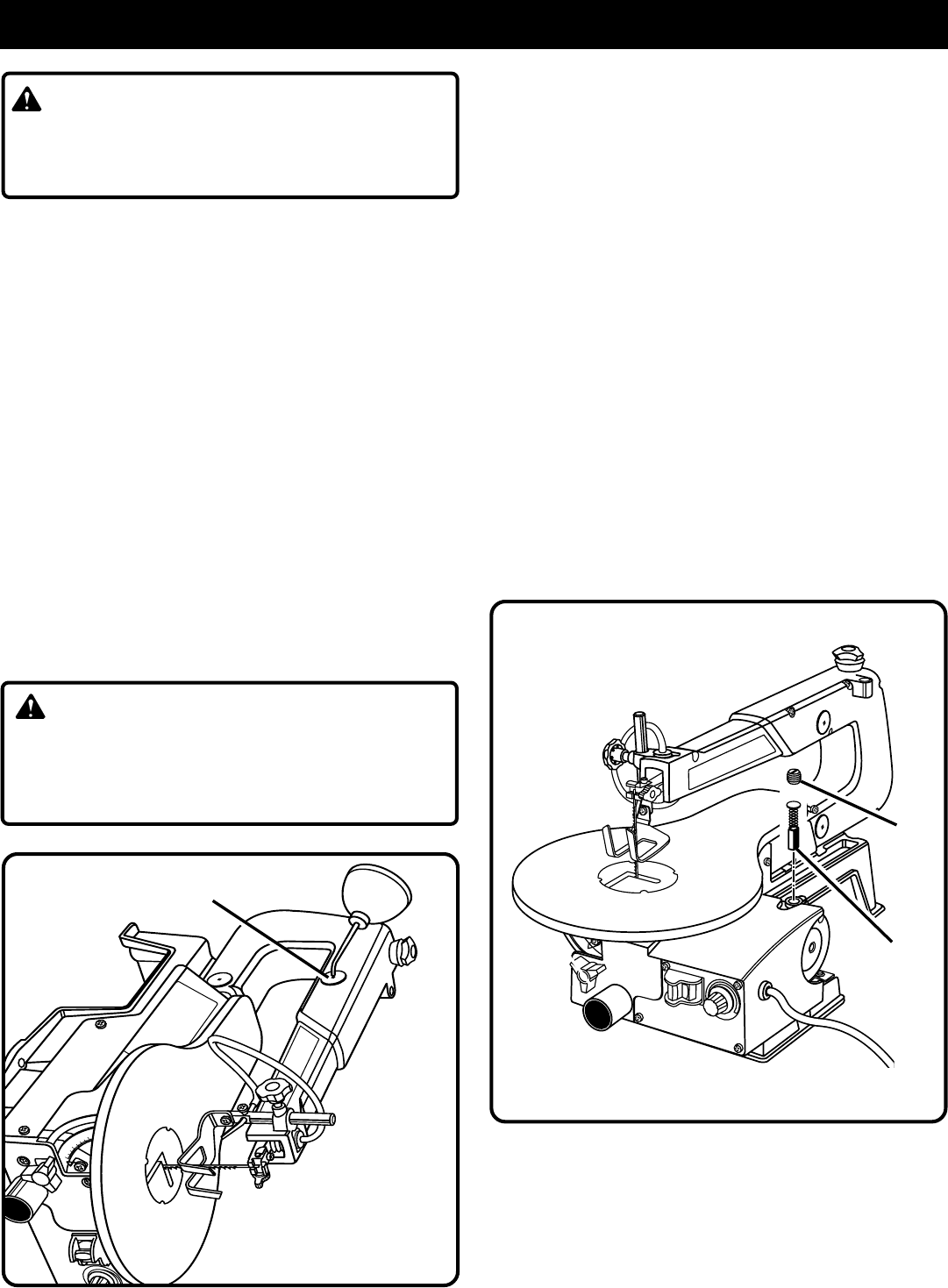

See Figure 16.

Your saw has externally accessible motor brush assemblies

that should be checked periodically for wear. When one of

the two brushes becomes worn, replace both brushes.

■ Unplug the saw from the power source.

■ Carefully place the saw on its side exposing the under-

side of the saw housing.

■ Using a flat blade screwdriver, remove the bottom brush

assembly cap through the access hole in the base and

the top brush assembly cap from the top of the motor.

Gently pry the brush assemblies out using a small screw

drivier, point of a nail, or paper clip.

■ If one motor brush is worn down shorter than 1/4 in. (6

mm), replace both motor brushes. Do not replace one

side without replacing the other. Make sure curvature of

brush matches curvature of motor and that the motor

brush moves freely in brush tube. Use the blunt end of

something thin (eraser end of pencil, etc.) to push the

motor brush into the tube until it stays.

■ Make sure the motor brush cap is oriented correctly

(straight). Tighten motor brush cap using a hand

powered screwdriver only. Do not overtighten.

MAINTENANCE

Fig. 15

ARM BEARING

0

3

0

15

Fig. 16

BRUSH

CAP

MOTOR

BRUSH