2.* Loosen yoke clamp handle (item 2, figure 18) by pulling

the. handle horizontally toward the front of the saw.

3. Slightly loosenthe two hex head machine _rews (item 3,

figure 18).

4. Rotate the yoke (item 4, figure 18) very slightly oppo_ite

to the direction of heel. (For left heel, rotate yoke clock-

wise;forrightheel rotateyoke counterclockwise.)

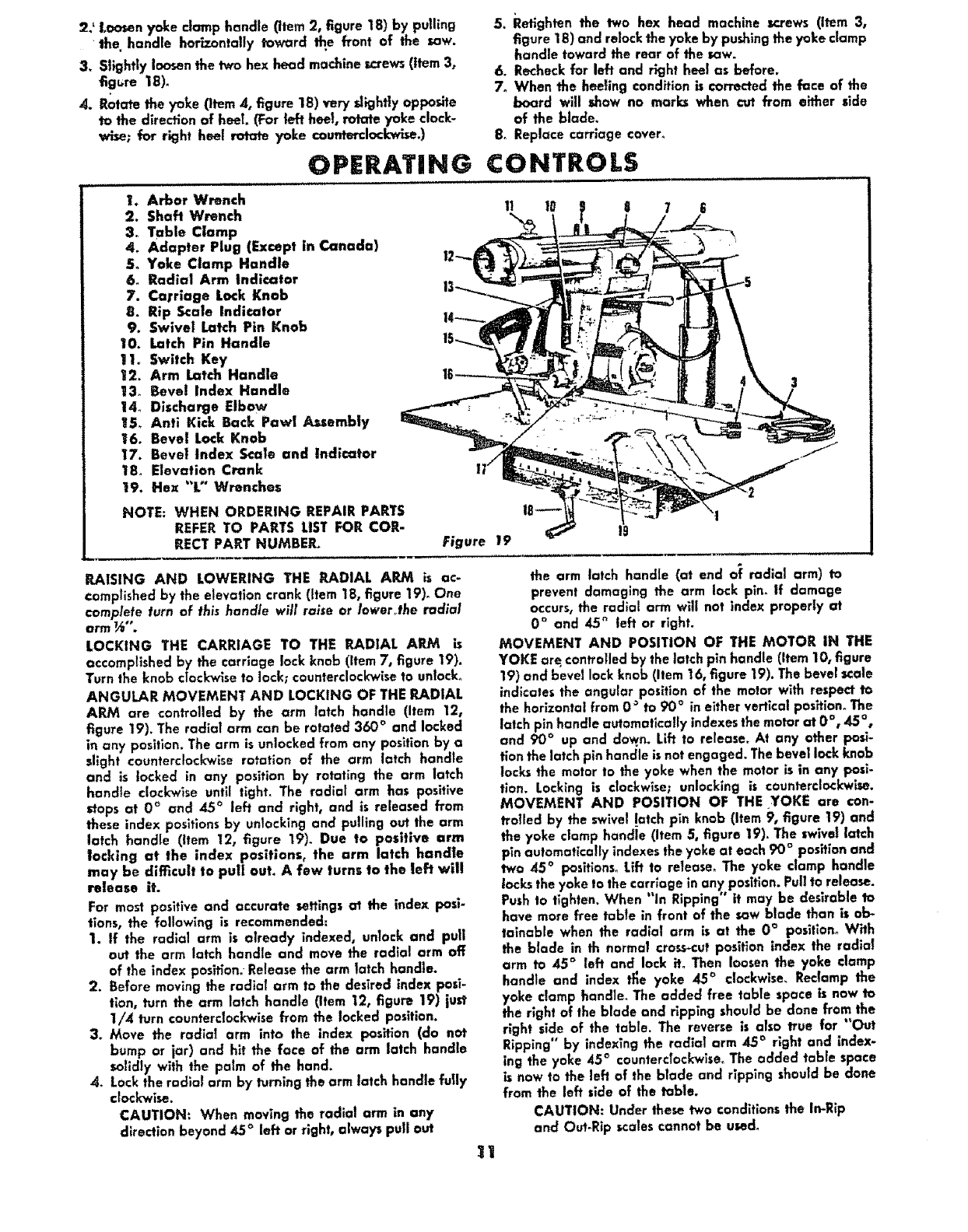

OPERATING

1. Arbor Wrench

2. Shaft Wrench

3_ Table Clamp

4. Adapter Plug (Except in Canada)

5o Yoke Clamp Handle

6. Radial Arm Indicator

7. Carriage Lock Knob

8. Rip Scale Indicator 14----.._

9. Swivel Latch Pin Knob

10. Latch Pln Handle

1Io Switch Key

12. Arm Latch Handle

13_ Bevel Index Handle

14_ Discharge Elbow

15. Anti Kick Back Pawl Assembly

16. Bevel Lock Knob

17. Bevel Index Scale and indicator

18. Elevation Crank

19. Hex "'L" Wrenches

5. Refighten the two hex head machine screws (item 3,

figure 18) and relock the yoke by pushingthe yoke clamp

handle toward the rear of the saw.

6. Recheck for left and right heel as before.

7o When the heeling condition is corrected the face of the

board will shaw no marks when cut from either side

of the blade.

B° Replace carriage cover_

CONTROLS

NOTE: WHEN ORDERING REPAIR PARTS

REFER TO PARTS LIST FOR COR-

RECT PART NUMBER.

Figure _9

RAISING AND LOWERING THE RADIAL ARM is ac-

complished by the elevation crank (Item 18, figure 19). One

complete turn of this handte will raise or lower_the radial

€l/'m _,_".

LOCKING THE CARRIAGE TO THE RADIAL ARM is

accomplished by the carriage lock knob (Item 7, figure 19).

Turn the knob clockwise to lock; counterclockwise to unlock.

ANGULAR MOVEMENT AND LOCKING OF THE RADIAL

ARM are controlled by the arm latch handle (item 12,

figure 19). The radial arm can be rotated 360 ° and locked

in any position. The arm is unlocked from any position by a

slight counterclockwise rotation of the arm latch handle

and is locked in any position by rotating the arm latch

handle clockwise until tight. The radial arm has positive

stops at 0 ° and 45 ° left and right, and is released from

these index positions by unlocking and pulling out the arm

latch handle (Item 12, figure 19). Due to positive arm

locking at the index positions, the arm latch handle

may be difficult to pull out. A few turns to the left will

release i|.

For most positive and accurate settings at the index posi-

tions, the following is recommended:

1. if the radio1 arm is already indexed, unlock and pull

out the arm latch handle and move the radial arm off

of the index position. Release the arm latch handle.

2. Before moving the radial arm to the desired index posi-

tion, turn the arm latch handle (item 12, figure 19) just

1/4 turn counterclockwise from the locked position.

3. Move the radia! arm into the index position (do not

bump or jar) and hit the face of the arm latch handle

solidly with the palm of the hand.

4. Lockthe radial arm by turning the arm latch handle tufty

clecl_,vise.

CAUTION: When moving the radial arm in any

direction beyond _° left or right, always pull out

11

the arm latch handle (at end of radial arm) to

prevent damaging the arm lock pln_ If damage

occurs, the radial arm wiff not index properly at

0 ° and 45_ left or right.

MOVEMENT AND POSITION OF THE MOTOR IN THE

YOKE are,controlled by the latch pln handle (item 10, figure

19) and beveZlock knob (Item 16, figure 19). The bevel scale

indicates the angular position of the motor with respect to

the horizontal from 0 _ to 90 ° in either vertical pos'rtionoThe

latch pin handle automatically indexes the motor at 0°, 45 °,

and 90 ° up and da'_n. Lift to release. At any other posi-

tion the latch pin handle isnot engaged. The bevel lock knob

locks the motor to the yoke when the motor is in any posi-

tion. Locking is clockwise; unlocking is counterclockwise.

MOVEMENT AND POSITION OF THE YOKE are con-

troffed by the swivel latch pin knob (Item 9, figure 19) and

the yoke clamp handle (Item 5, figure 19). The swivel latch

pin automatically indexes the yoke at each 90 ° position and

two 45 ° positions_ Lift to release_ The yoke clamp handle

locksthe yoke to the carriage in any position. Pull to release.

Pushto tighten. When "in Ripping" it may be desirable to

have more flee table in front of the saw blade than is oh-

tainable when the radial arm is at the 0° posltlon_ With

the blade in th normal cross-cut position index the radial

arm to 45 ° left and lock it. Then loosen the yoke clamp

handle and index tile yoke 45 ° clockwise_ Redamp the

yoke clamp handle. The added free table space is now to

the right of the blade and ripping should be done from the

right side of the table. The reverse is also true for "Out

Ripping" by indexing the radial arm 45 ° right and index-

ing the yoke ,45° countercTackwlse_ The added table space

is now ta the left of the blade and ripping should be done

from the left s_de of the table.

CAUTION: Under these two conditions the In-Rip

and Out-Rip scales cannot be used.