1_ Loo_n Tne Qamplng _or_w'_ _wn_ mJ _tl _m _€;,nne'ls

• (item 2).

2. Adiust nuts(Item 3) by alternating loosening and tighten-

ing so that the channels are moved up or down an the

a_justing screws(Item 4) in the desired direction.

3. When channels are properly adjusted the arbor wrench

wifl just contact the table top when swung back and forth

at Positions 1, 2, 3, and 4 of Figure 9_ Tighten clamping

screws (Item 1). Recheck the four positionsto insure that

no change has occurred.

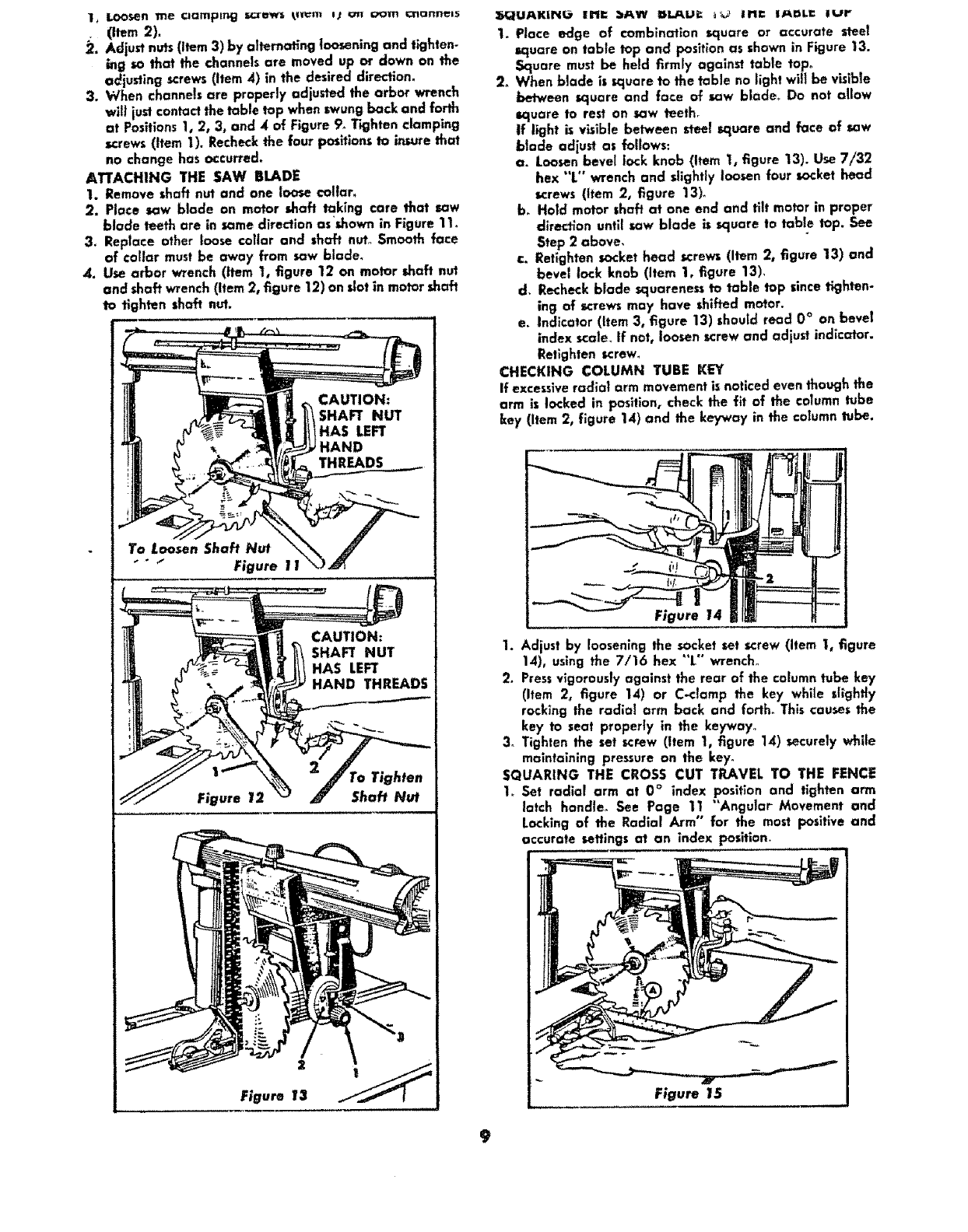

ATTACHING THE SAW BLADE

1. Remove shaft nut and one loose col|arm

2. Place saw blade on motor shaft taking care that saw

blade teeth are in some direction asshown in Figure 11_

3. Replace other loose coltar and shaft nut° Smooth face

of €ol|or must be away from saw blade.

,4. Use arbor wrench (item 1, figure 12 on motor shaft nut

and shaft wrench (Item 2, figure 12) on slot in motor shaft

to tighten shaft nut.

CAUTION:

SHAFT NUT

HAS LEFT

HAND

THREADS

To Loosen Shaft Nut

" °"_ Figure 11

CAUTION:

SHAFT NUT

HAS LEFT

HAND THREADS

Figure 12

ro Tighten

Shaft Nut

2

Figure 13

:_IUAICII_ UM" :_AW ISI.AU= _ In" IAnLC lur

1. Place edge of combination square or accurate steel

square on table top and position as shown in Figure 13.

Square must be held firmly against table tap°

2. When blade is_uare to the table no light will be v_ible

between square and face of saw blade. Do not allow

square to rest on saw teeth.

If light is visible between steel square and face of sow

blade adjust as follows:

a. Loosenbevel lock knob (Item I, figure 13). Use 7/32

hex "L" wrench and sllghfly loosen four socket head

screws (item 2, figure 13).

b. Hold motor shaft at one end and tilt motor in proper

direction until saw blade is square to table top. See

Step 2 above_

c. Retlghten socket head screws (Item 2, figure 13) and

bevel lock knob (Item 1, figure 13).

d. Recheck blade _uareness to table top since tighten-

ing of screws may have shifted motor.

e. Indicator (item 3, figure 13) should read 0° on bevel

index scole_If not, loosen screw and adjust indicator.

Retlghten screw.

CHECKING COLUMN TUBE KEY

if excessiveradla| arm movement is noticed even though the

arm is locked in position, check the fit of the column tube

key (Item 2, figure 14) and the keyway in the column tube.

Figure 14

1. Adjust by loosening the socket set screw (Item I, figure

14), using the 7/16 hex "'L'"wrench°

2. Pressvigorously against the rear of the column tube key

(Item 2, figure 14) or C-clamp the key while slightly

rocking the radial arm back and forlh. This causes the

key to seat properly in the keyway°

3o Tighten the set screw (item 1, figure 1`4)securely whffe

maintaining pressure on the key°

SQUARING THE CROSS CUT TRAVEL TO THE FENCE

1_ Set radial arm at 0 ° index position and tighten arm

latch handle_ See Page 11 "Angular Movement and

Locking of the Radial Arm" for the most positive and

accurate sewings at an index Posilion,

Figure 15

9