Figure 25

Figure 36

BOiUNG

Your saw can also be €onveded 1o a horZzonta| drill for

boring by using one of the recommended c_ucks ahd the

proper drill For drilling holes on an angle the radial arm

d_ould be positioned to the desired angle while the work is

parallel to the fence, See Figure34.

SANDING

Using the 10" sanding disc mounted on the saw end of the

motor, you can convert your saw into a sander which can be

operated in any position° The loose collars should be used

on both sides of the sanding disc°

STABILIZING WASHERS FOR THIN bLADES

Stabilizlng washers should be used with thin btades for

improved appearance of the finish cuts.

HELPFUL HINTS

1_ The life of the laminated saw table can be greatly length-

ened if a 1¼,,piece of plywood istacked to the table top

after leveling Then all cutting can be done in the added

plebe of plywood instead of the laminated table.

_. There is a posslbility that during or after shipment, the

wooden front tab|e; spacer board, or rear table might

became slightly warped Lay a straight edge across the

surface of the table and check for gaps or high spotson

the table. Any portions of the table which are not fiat

should be planed and sanded until flat Sanding can be

done by using one of the two key chucksreferred to

under "'Routing" and a Craftsman moulded rubber 7"

sanding disc_

2. When sanding the table top (See Figure 35) oI"routing

with the work stationary, the arm lock pln can be pre-

vented from automotlcally indexing at 0 ° and 45 ° by

rotating the arm latch handle about 6 turns counter-

clockwise from the locked position_

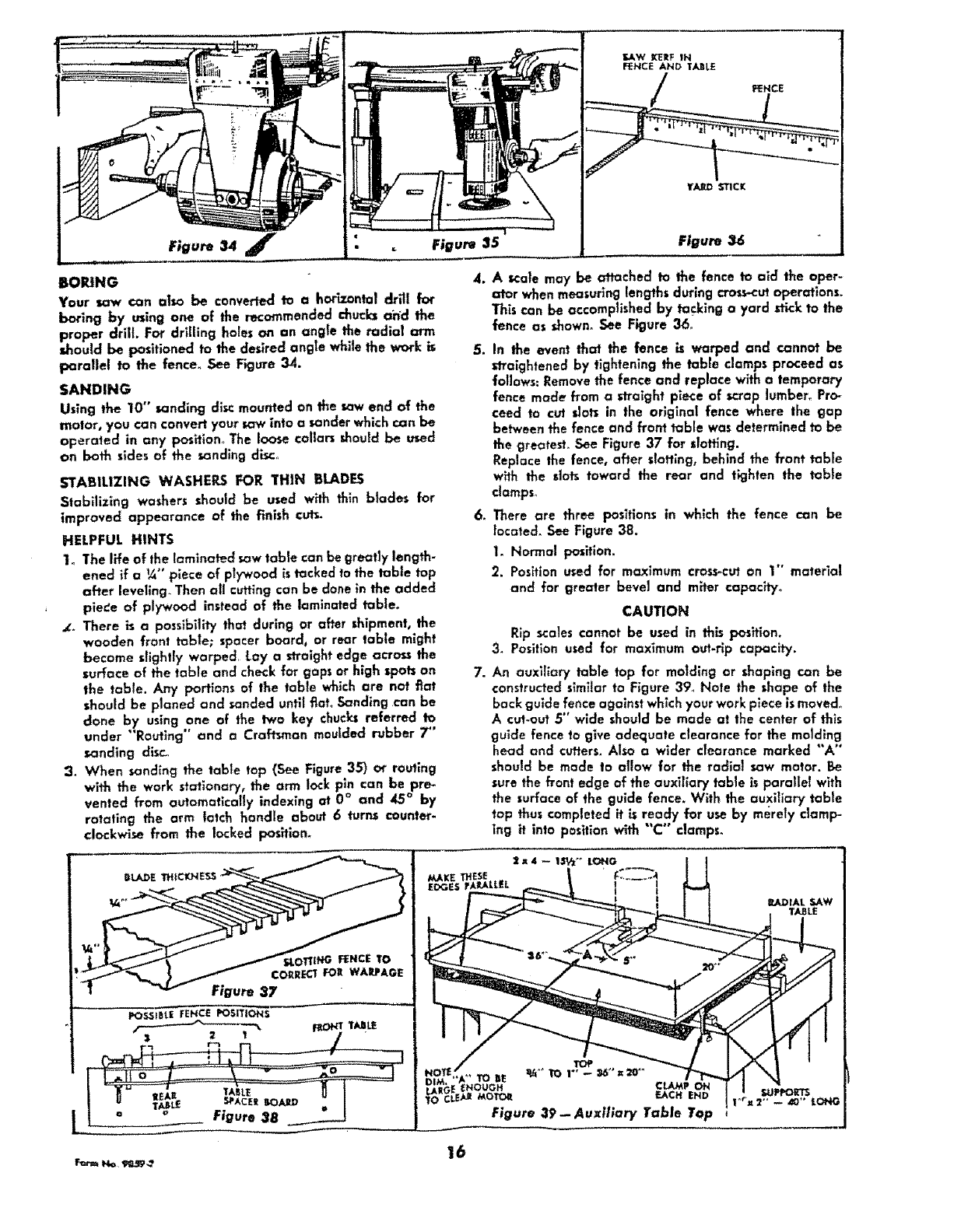

4. A scale may be attached to the fence to aid the oper-

at'or whenmeasuring lengths during cToss-cutoperations.

This can be accomplished by ta_ing a yard stick to the

fence as shown° See Figure 36_

S. In the event that the fence is warped and cannot be

straightened by tightening the table clamps proceed as

follows: Removethe fence and replace with a temporary

fence made from a straight piece of scrap lumber_ Pro-

ceed to cut slot_ in the original fence where the gap

between the fence and front table was determined to be

the greatest_ See Figure 37 for slotting.

Replace the fence, after slotting, behind the front table

with the dots toward the rear and tighten the tabte

damps_

6. There are three positions in which the fence can be

located. See Figure 38.

I. Normal position.

2. Position used for maximum cross-cut an 1" material

and for greater bevel and miter capacity°

CAUTION

Rip scales cannot be used in this F_>sltlon.

3_ Position used for maximum out-Hp capQcff',/.

7. An auxiliary table top for molding or shaping can be

constructed slmffar to Figure 39_ Note the shape of the

back guide fence against which your work p_eceis moved°

A cut-out 5" wide should be made at the center of this

guide fence to give adequate clearance for the molding

head and cutters. Also a wider clearance marked "'A°'

should be made to allow for the radial saw motor. Be

sure the front edge of the auxiliary table is parallel with

the surface of the guide fence. With the auxiliary table

top thus completed it is ready for use by merely damp-

lng it into position with "C °' clamps.

2_4 -- I,._A_°_ LONG

EDGES rA_LALLEL I I

! lAD IAL SAW

TABLE

Figure 37

_,_ _ 16