ADJUSTMENTOF RiPSCALEINDICATORS

Whenthefenceisinitsnormalposition(nexttothefront

table),indextheyoke90 ° from the €_oss-cut position so

that the blade is between the motor and the fence° Lock

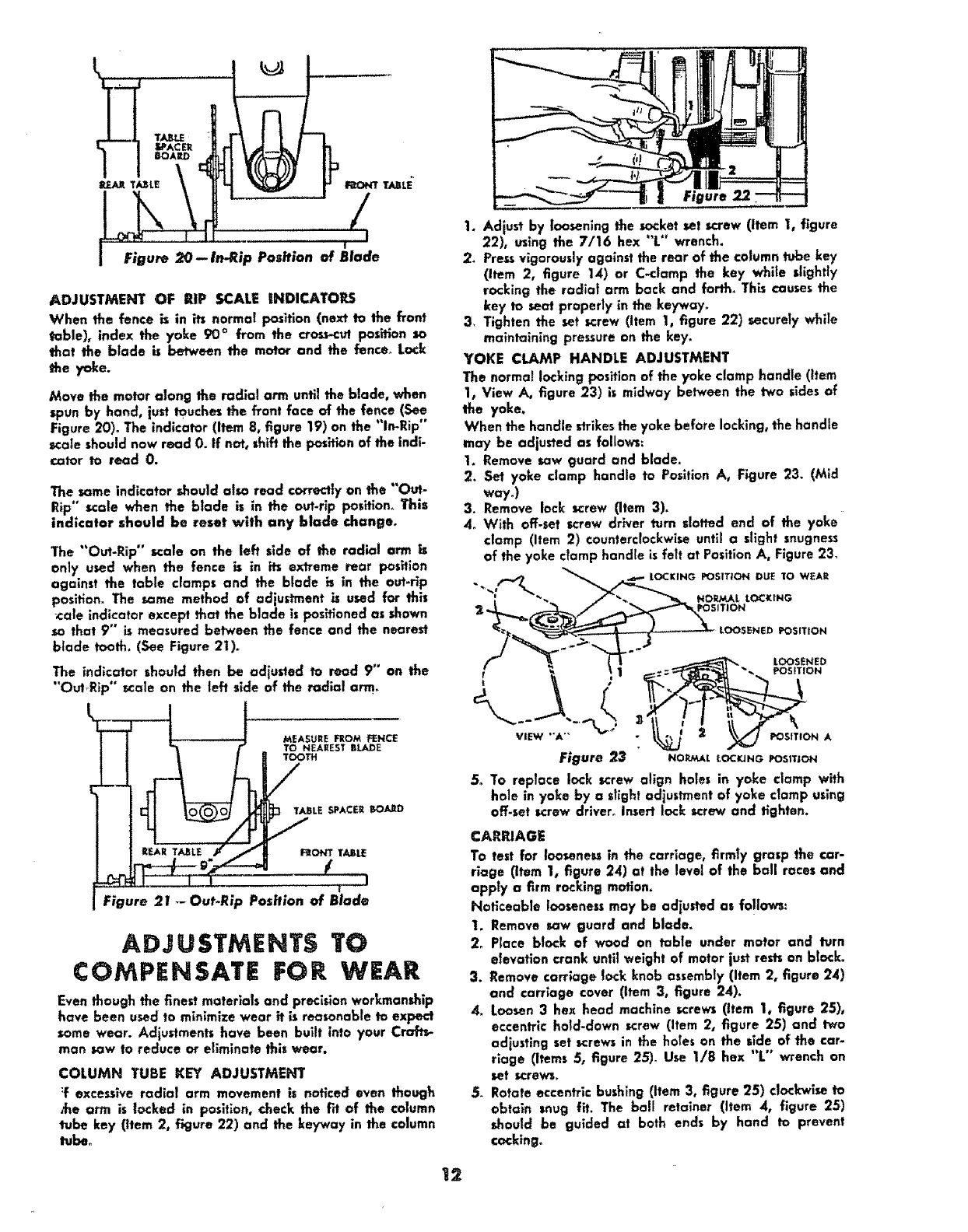

Move the molar along the radial arm uoti_the blade, when

spun by hand, just _uches the front face of the fence (See

Figure 20)° The indicator (Item 8, figure 19) on the "In-Rip"

scale should now read 0. If not, shift the position of the indi-

ca|at to read 0.

The same indicator should also read correctly on the "'Out-

Rip" scale when the blade is in the out-rip positlon_ This

indicator should be reset with any blade change.

The "Out-Rip" scale on the left side of the radial arm is

only used when the fence is in its extreme rear position

against the table clamps and the blade is in the out-rlp

position. The some method of adjustment is used for this

cote indicator except that the blade ispositioned as shown

so that 9°° is measured between the fence and the nearest

blade tooth. (See Figure 2I).

The indicator should then be adjusted to read 9" an the

"Out-Rip" _cale on the left side of the radial arm_

hEAR T,/_ LEg._

MEASURE FROM FENCE

TO NEAREST BI.J_DE

TOOTH

I

Figure 21 .-Out-Rip Position of Blade

ADJUSTMEHT$ TO

COMPENSATE FOR WEAR

Even though the finest materials and procidon workmanship

have been u_ed to minimize wear it is reasonable to expect

some wear. Adjustments have been built into your Croft_

man sow to reduce or eliminate this wear.

COLUMN TUBE KEY ADJUSTMENT

:f excessive radlat arm movement is noticed even though

,t_e arm is locked in position, check the fit of the column

tube key (item 2, figure 22) and the key'way in the column

tuber

Figure

1. Adjust by loosening the socket set screw (item I, figure

22), using the 7/16 hex "t" wrench.

2. Prexsvigorously against the rear of the column tube key

(Item 2, figure 14) or C-clamp the key while slightly

rocking the radial arm back and forth_ This causes the

key to seat properly in the keywoTo

3, Tighten the set screw (Item 1, figure 22) securely while

maintaining pressure on the key.

YOKE CLAMP HANDLE ADJUSTMENT

The normal locking position of the yoke clamp handle (item

1, View A_ figure 23) is midway between the two sides of

the yoke.

When the handle strikesthe yoke before locking, the handle

may be adjusted as follows:

1. Remove sow guard and blade.

2. Set yoke clamp handle to Position A, Figure 23. (Mid

way.)

3. Remove lock screw (Item 3).

4o With off-set screw driver turn slotted end of the yoke

clamp (Item 2) counterclockwise until a slight snugness

of the yoke clamp handle is felt at PositionA, Figure 23.

a___s G _osmoN ou_ To WEAR

NOR/€_ L LOCKING

1710N

..-..3._ LOOSENED _SITION

_ "" LOOSENED

POSitION A

Figure 23 NO_U,_,_OC_NGPOSlnON

5o To replace lock screw align holes in yoke clamp with

hole in yoke by a slight odiustment of yoke clamp using

off-set screw driver° Insert lock screw and tighten.

CARRIAGE

To test for loosenessin the carriage, firm|y grasp the car-

riage (Item 1, figure 24) at the levet of the baff races and

apply a firm rocking motion.

Noticeable looseness may be adiusted as follows:

1. Remove sow guard and blade.

2o Place block of wood on table under motor and turn

elevation crank until weight of motor just rests on block.

3. Remove carriage lock knob assembly (Item 2, figure 24)

and carriage cover (Item 3, figure 24).

4. Loosen 3 hex head machine screws (item 1, figure 25),

eccentric hold-down screw (Item 2, figure 25) and two

adjusting set screwsin the holes on the side of the car-

riage (Items 5, figure 2S)o Use 1/8 hex "L" wrench on

set screws,

5_ Rotate eccentric bushing (Item 3, figure 25) clockwise to

obtain snug fit. The bali retainer (Item 4, figure 25)

should be guided at both ends by hand to prevent

cocking°

12