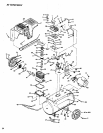

KEY

NO. PART NUMBER

"73 265-1tl

74 C-BT-215

75 STD523107

76 SSN-1014-ZN

77 265 -2

78 265-9

79 265-23

"80 265-13

81 _.265:.L

82 SSW-7367

83 21181-506

SSH-8

9-16163

SI-30-09-1-D

630-01

•Parts Ordering Information

Key No 9, 53, 67, 70, 72, 73,

919.17631.1& 919.176320).

PARTS LIST (Continued)

DESCRJPTION

Oil seal

Poly-V-beit

Cap screw 5A="-18× %"

Belleviile washer

Flywhee]

End plate i

Needle bearing

End plate gasket

Crankshaft

Strain relief (2 used)

Lockwasher (2 used)

NOT ILLUSTRATED

Air Chuck

Air Hose Assembly (%" x i5')

Owners Manual

"Power Painting With Sprayer" booklet

80 available as individual parts and as part of kit KK-4268 (Models 919.176210.

Key No. 9, 53, 67, 70A, 72, 73, 80 available as individual parts and as part of KK-4312 (Model 919.176330)

Key No, 60, 61, 62 only available as part of rtng kit KK-4209 (Models 919.176210,919.17631,1& 919.176320).

Key No. 60A, 61A, 62A only available as part of ring kit KK-4313 (Model 919.176330),

Key No. 19 pressure release valve and nut available as part of KK-4315.

Key No. 64, 66, 68 only available as part of valve kit KK-4275.

1"Internal parts can be purchased as regulator repair kit KK-4294.

ACCESSORIES FOR USE WITH SEARS CRAFTSMAN COMPRESSORS AVAILABLE THROt

THE CURRENT GENERAL SEARS CATALOG OR AT FULL LINE SEARS STORES.

1. Spray Guns 9. Inflator Kits

2. Sandblasters 10. Quick Connector Sets: various sizes

3. P_int Tanks

4, Blow Guns

5. Air Brushes

6. Air Tanks

7. Air Tools: sanders, drills, impact wrenches,

hammers

8. Air Hose: 1/4",5/1_"or =/a"inside diameter, 15', 25', "

11. VJscosimeter

12. Air Line Filters

13. Oil Fog Lubricators

14, Tire Air Chucks

15. Air Caulking Gun

15. Air Powered Washer Gun

50' lengths TROUBLESHOOTING GUIDE

P-RFORMING TROUBLESHOOTING OR REPAIRS MAY EXPOSE VOLTAG_ £CJRC=g, MOVING PART_. _.

COMPRESSED AIR SOURCES, PERSONAL INJURY MAY OCCUR IF EXPC'5-7-. ¢._;OP, TO ATT_.MPTING Ai

TROUBLESHOOT|NG OR REPAIRS, THE COMPRESSOR MUST BE DISCONN,CTED FROM THE POWER SOURC

NEVER OPERATE THE OUTFIT WITH THE CONSOLE REMOVED, THE CONSOLE SHOULD B__ REMOVED ON.

WH_,N THE POWER CORD IS DISCONNECTED.

PROBLEM

Motor Will Not Run

CAUSE

....... ,,,,,,,

Motorov,rJ0adprof..on

has tripped.

Tank pressure exceeds pressure

switch cut-in pressure:

CORRECTION

Let motor cool off and reset switch by pres-

sing the red reset button located on the enc

of motor. See motor section on page 6.

Motor will start automatically when tanl

pressure drops below cut-in pressure o

pressure switch.