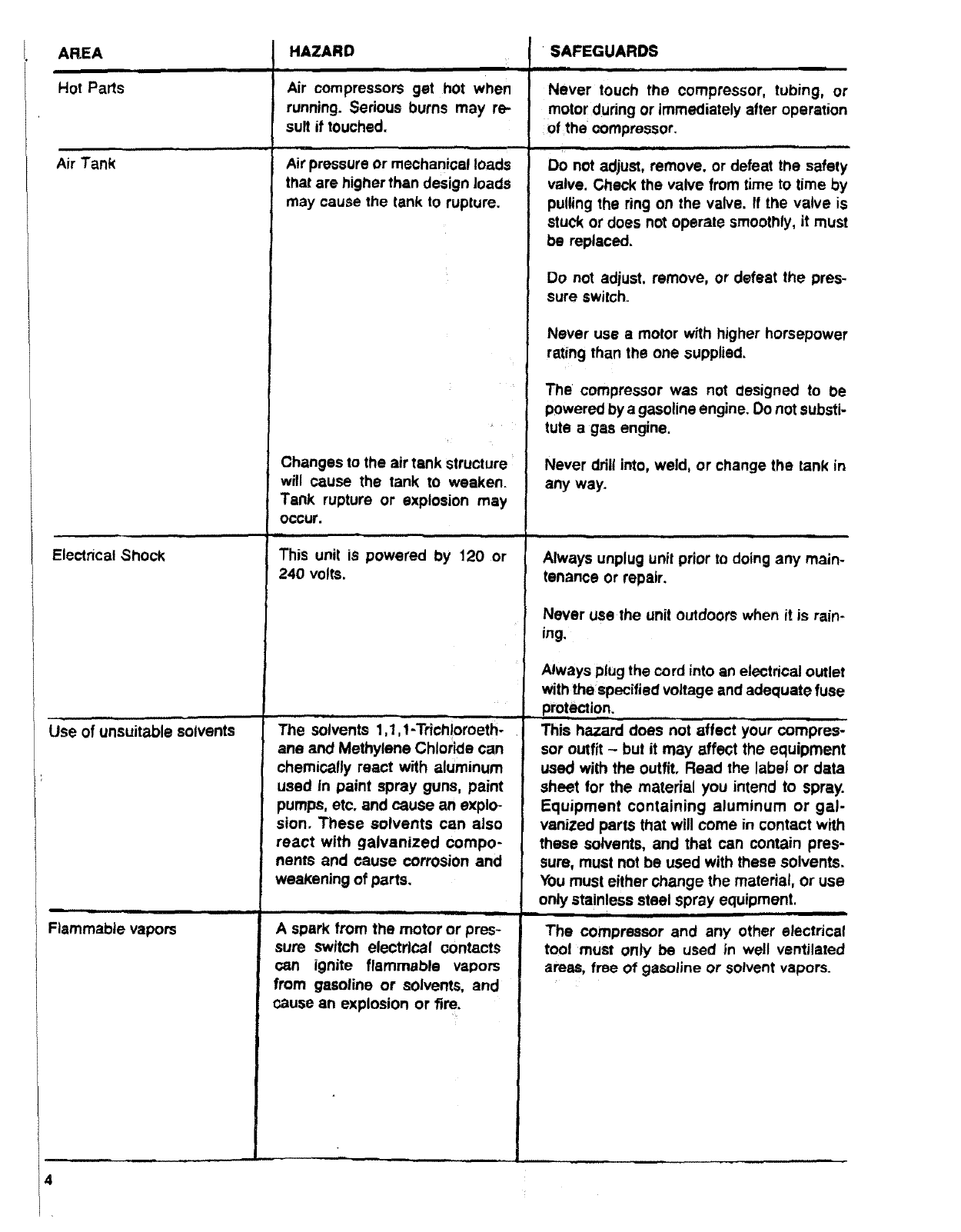

AREA

Hot Parts

Air Tank

Electrical ,Shock

Use of unsuitable solvents

Flammable vapors

HAZARD

i ii

Air compressors get hOt when

running. Serious burns may re-

sult if touched.

Air pressure or mechanical loads

that are higher than design loads

may cause the tank to rupture.

Changes to the air tank structure

will cause the tank to weaken

Tank rupture or explosion may

occur.

iiiii IHIIII I

This unit is powered by 120 or

240 volts.

The solvents 1,1,1-Tdchloroeth-

ane and Methylene Chlo_de can

chemically react with aluminum

used in paint spray guns, paint

pumps, etc. and cause an explo-

sion. These solvents can also

react with galvanized compo-

nents and cause corrosion and

weakening of parts.

iiiiiiiiiiiiiiii iiii

A spark from the motor or pres-

sure switch electrical contacts

can ignite flammable vapors

from gasoline or sOlvents, and

cause an explosion or fire.

SAFEGUARDS

,,,i ..................... ii ,i

Never touch the compressor, tubing, or

motor during or immediately after operation

of the compressor.

DO not adjust, remove, or defeat the safety

valve. Check the valve from time to time by

pulling the ring on the valve. If the valve is

stuck or does not operate smoothly, it must

be replaced.

Do not adjust, remove, or defeat the pres-

sure switch.

Never use a motor with higher horsepower

rating than the one supplied.

The compressor was not designed to De

powered bya gasoline engine. Do not substi-

tute a gas engine.

Never drill into, weld, or change the tank in

any way.

,,,,,,,,,,,,,,i

Always unplug unit prior to doing any main-

tenance or repair.

Never use the unit outdoors when it is rain-

ing.

Always plug the cord into an electrical outlet

with the specified voltage and adequate fuse

protection.

This hazard does not affect your compres-

sor outfit - but it may affect the equipment

used wilh the outfit. Read the label or data

sheet for the material you intend to spray.

Equipment containing aluminum or gal-

vanized parts that will come in contact with

these solvents, and that can contain pres-

sure, must not be used with these solvents.

You must either change the material, or use

only stainless steel spray equipment.

ii III

The compressor and any other electrical

tool must only be used in well ventilated

areas, free of gasoline or solvent vapors.