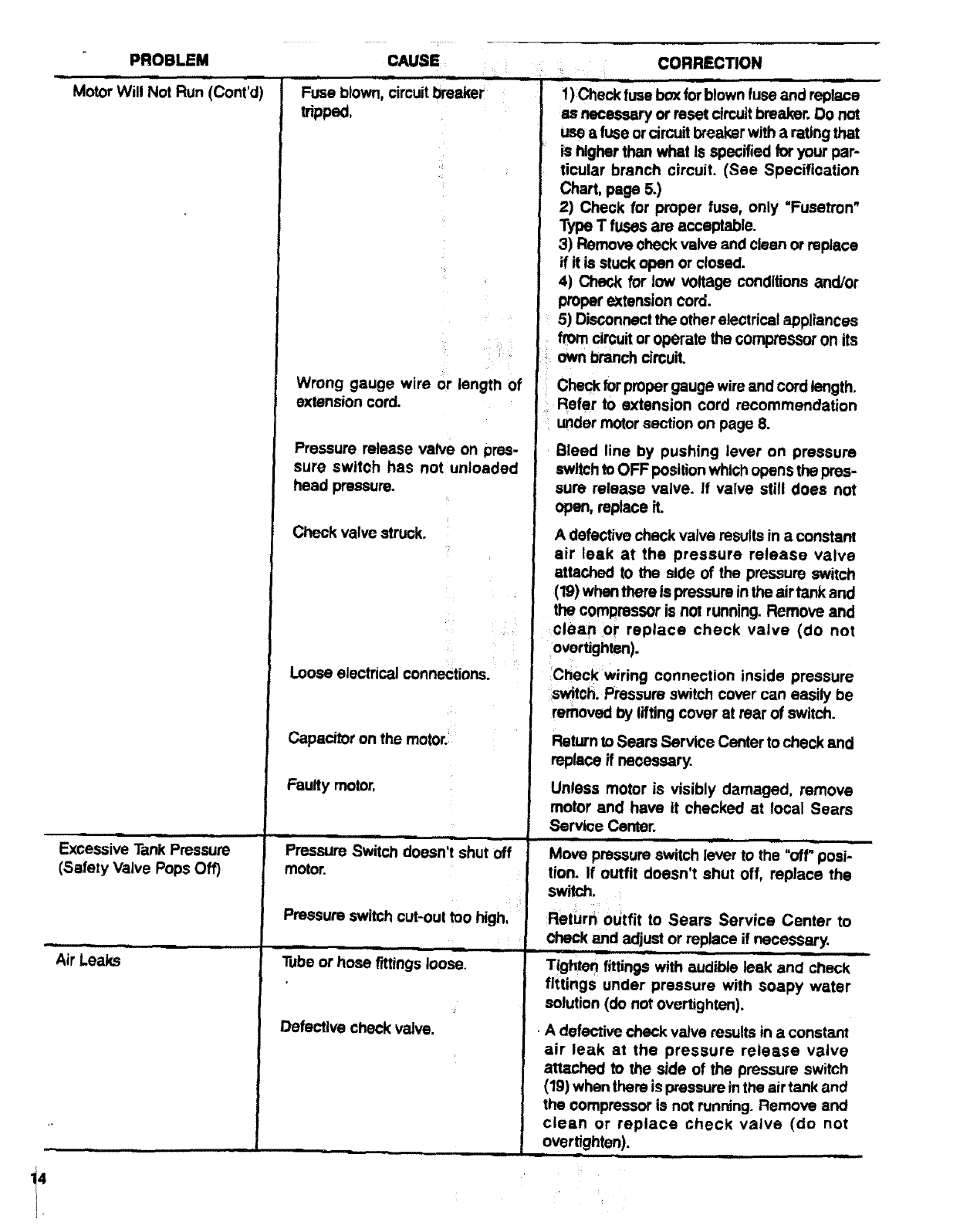

PROBLEM

Motor Will Not Run (Cont'd)

Excessive Tank Pressure

(Safety Valve Pops Off)

Air Leaks

I'

CAUSE

ii, i

Fuse blown, circuitbreaker

pped,

Wrong gauge wire Or length of

extension cord.

Pressure release valve on pres-

sure switch has not unloaded

head pressure.

Check valve struck.

Loose electrical connections.

Capacitor on the motor.

Faulty motor.

Pressure Switch doesn't shut off

motor.

Pressure switch cut-out too high,

, i,, i

Tube or hose r_tings loose.

Defective check valve.

i

CORRECTION

iiiii iiii

!) Check fuse box for blown fuse and replace

as necessary or reset circuitbreaker. Do not

use a fuse orcircuit breaker with a rating that

is higher than what is specified for your par-

ticular branch circuit. (See Specification

Chart, page 5.)

2) Check for proper fuse, only "Fusetron"

Type T fuses are acceptable.

3) Remove check valve and clean or replace

if it is stuck open or closed.

4) Check for low voltage conditions and/or

proper extension cord.

5) Disconnect the other electrical appliances

from circuitor operate the compressor on its

own branch circuit

Check forproper gauge wire and cord length.

Refer to extension cord recommendation

under motor section on page 8.

Bleed line by pushing lever on pressure

switchto OFF position which opens the pres-

sure release valve. If valve still does not

open, replace it.

A defective check valve results in a constant

air leak at the pressure release valve

attached to the side of the pressure switch

(19)when there is pressure in the air tank and

the compressor is not running. Remove and

clea n or replace check valve (do not

overtighten).

Check wiring connection inside pressure

switch. Pressure switch cover can easily be

removed by lifting cover at rear of switch.

Return to Sears Service Center tocheck and

replace if necessary.

Unless motor is visibly damaged, remove

motor and have it checked at local Sears

Service Center.

,i,.iiii ,,,,,,,

Move pressure switch lever to the "off"posi-

tion. If outfit doesn't shut off, replace the

switch.

Return outfit to Sears Service Center to

check and adjust or replace if necessary.

i jiiiiiii i iiiii ii

Tighten fittings with audible leak and check

fittings under pressure with soapy water

solution (do not overtighten).

. A defective check valve results in a constant

air leak at the pressure release valve

attached to the side of the pressure switch

(19) when there is pressure inthe air tank and

the compressor is not running. Remove and

clean or replace check valve (do not

overtighten).

J