-37-

W1677/W1711 10" Table Saw

OPERATIONS

Shop-Made Safety

Accessories

Shop-made safety accessories are another source of

devices to use to increase your safety while oper

-

ating the table saw. When care is taken with the

setup and design, shop-made tools can be an invalu

-

able resource for making the safest cuts possible.

Here are some of the basic items you may want

to consider:

• Push Sticks made from the shop are very popu

-

lar among table saw owners because they are

inexpensive and easy to make. Particularly

good are those that keep your hand a safe

distance away from the blade, offer stable

support and grip, and are comfortable in the

hand. Figure 59 shows an illustration of a sim-

ple push stick.

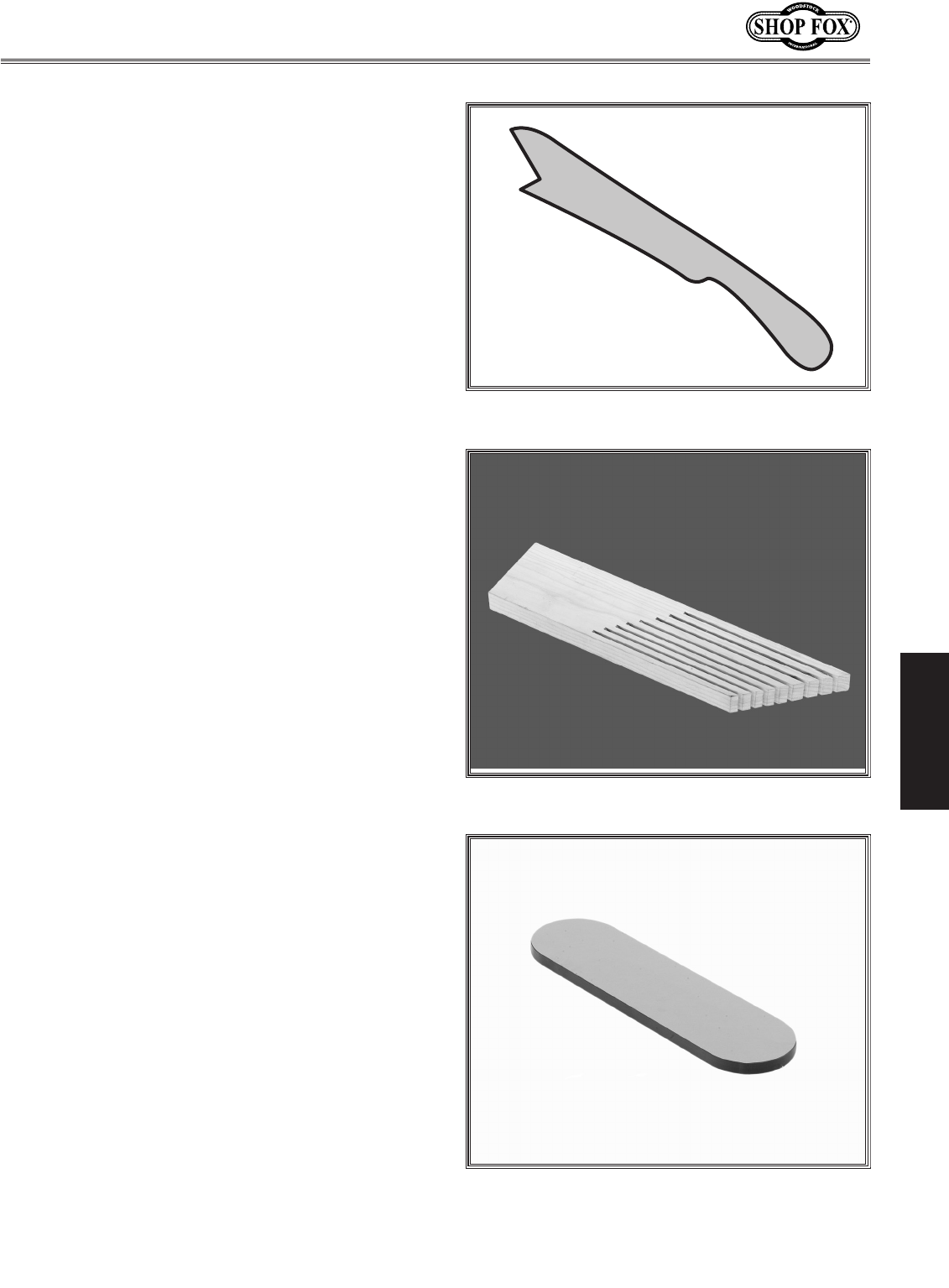

• Featherboards similar to the one in

Figure

60 make good anti-kickback devices. To use

these, they must be clamped to the table or

fence. The angled ends and flexibility of the

fingers allow the workpiece to move in one

direction and lock up if the workpiece moves

backwards.

• Zero-Clearance Table Inserts can be pur

-

chased or made from wood and substituted

for the factory inserts. The advantage in these

devices is that there will only be as much

space between the blade and the insert as the

blade requires. Many woodworkers have a dif-

ferent insert for different heights and blades.

Zero-clearance table inserts result in clean

cuts with less tear-out and a reduced chance

that a small piece of stock will be pulled down

inside the saw or will be kicked back. Figure

61 shows an example of a “blank” zero-clear-

ance insert. When making a zero-clearance

table insert, never hold the insert in place

with your hands or try to lower the insert onto

a moving blade. Hold or clamp the insert to

the table with a sacrificial board, and use a

smaller diameter blade to plunge the initial

cut through the insert.

Figure 60. Anti-kickback featherboard.

Figure 59. Illustration of a simple push stick.

Figure 61. Zero-clearance table insert.