ASSEMBLY

-17-

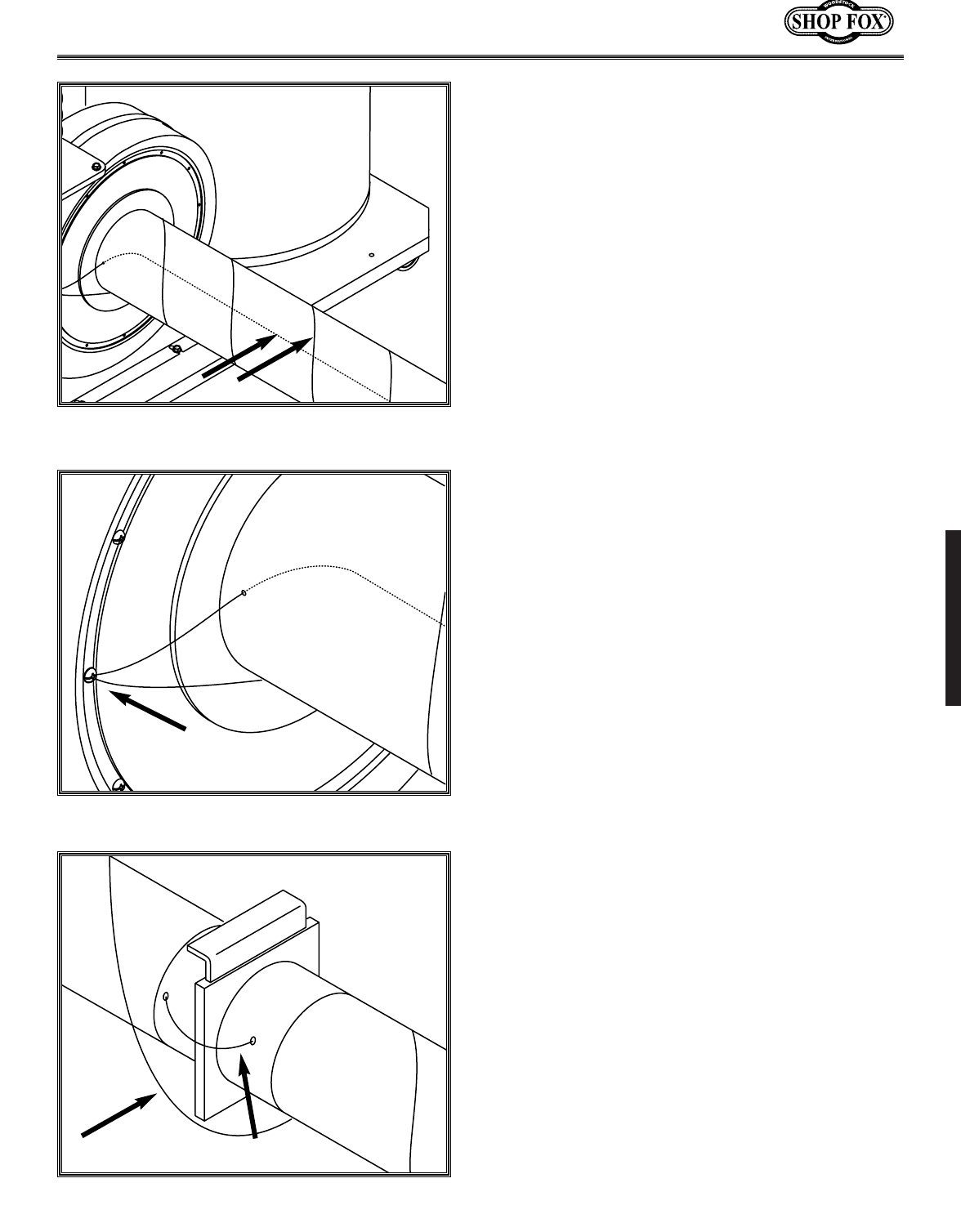

Figure 18. Wire inside and around pipe.

Figure 19. Ground wire secured to collector.

Figure 20. Ground wires bypassing blast gate.

System Grounding

Static electricity is generated by the collision of

dust particles as they travel through dust collec-

tion ducting. Plastic ducting acts as an insulator,

allowing the static charge to build. The build-up

of electricity will eventually discharge to the

nearest available grounding source. The dis-

charge will be in the form of a spark (arc) of

electricity that has the potential to ignite air-

borne dust, causing a fire or explosion hazard.

Therefore, your dust collection system must be

grounded by means of metal ducting throughout

the entire system or, when plastic pipe or hoses

are used, by bare copper wires.

If using metal ducting for the collection system,

ensure that each machine in the system forms a

conductive connection through the entire length

of duct work and back to the dust

impeller/motor assembly. If plastic hose or blast

gates are used between metal ducting anywhere

in the system, 12 gauge bare copper will need to

be used to “jump” the plastic conductive barri-

er and complete the conductive line between

the machine and the dust impeller/motor

assembly.

When the system is to be made up entirely of

plastic hoses and blast gates, wrap 12 gauge

bare copper wire around the hose from the dust

impeller/motor assembly to the machine body.

Another wire should be placed inside the

pipe/hose with exit holes for the wire at each

end of the hose run. After exiting the hose at

each end, the wire should connect to the dust

impeller/motor assembly and the machine body

as shown in Figures 18 and 19. If the system has

branches, place wires in the same fashion and

connect to the wires on the main pipe/hose with

wire nuts. If blast gates are to be used, drill exit

and entrance holes on both sides of the blast

gate to allow wire to be fed out of and into the

system as shown in Figure 20.