-49-

Model W1706 (Mfg. Since 8/10)

SERVICE

Shimming a Wheel

1. DISCONNECT BANDSAW FROM POWER!

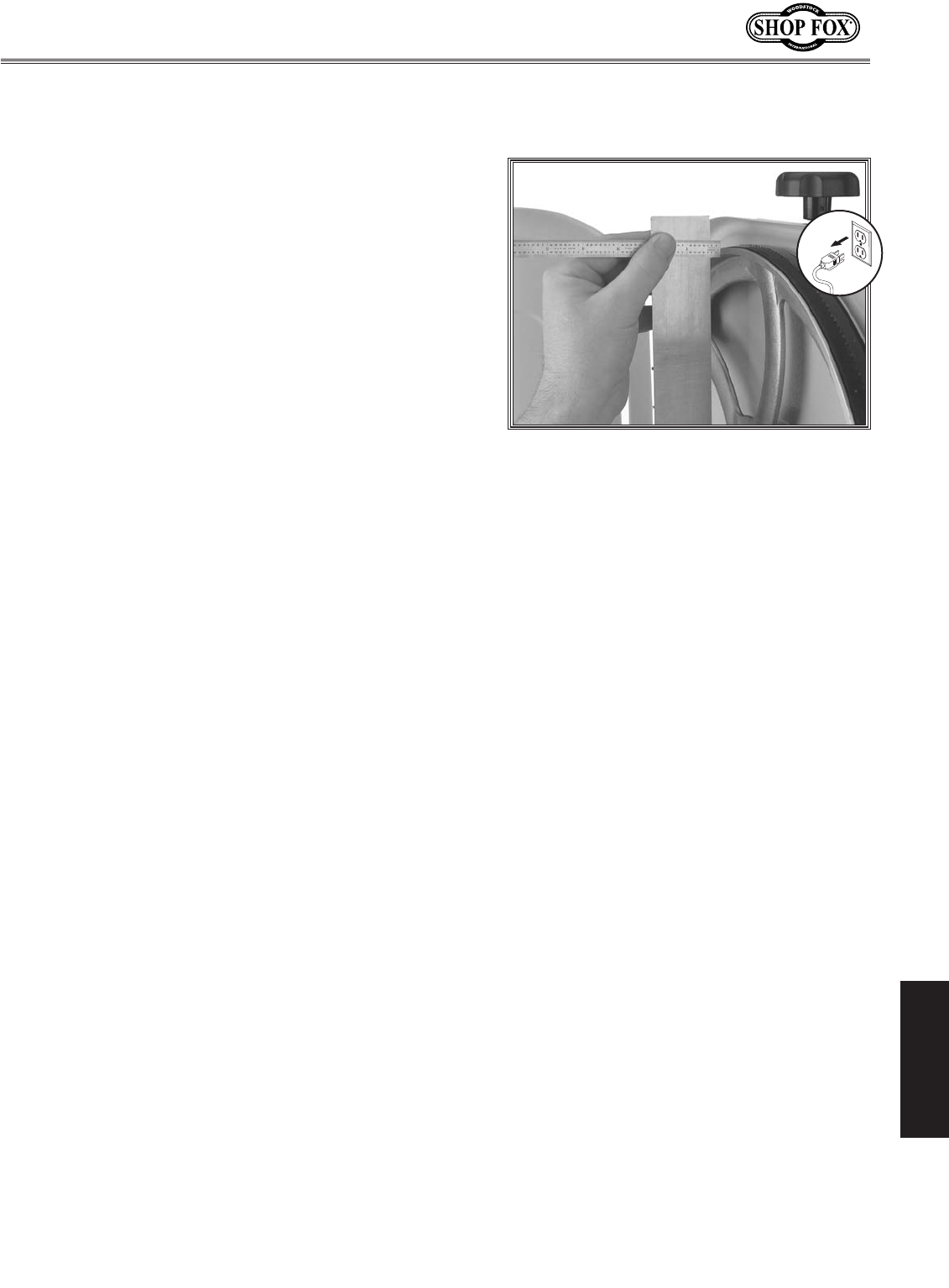

2. With a straightedge touching both points of

whichever wheel is forward most, measure the

distance the straightedge is away from the out-

of-adjustment upper wheel (see Figure 63 for an

example).

3. Remove the blade from the saw, then remove the

wheel that needs to be shimmed.

4. Determine the amount of shim washers necessary to

compensate for the distance measured in Step 3,

then place them on the wheel shaft.

5. Replace the wheel and the blade.

6. Properly tension the blade, then check the wheels

with the straightedge.

Note: Wheel coplanarity changes as the blade is

tightened, so it is best to check the wheel alignment

when the blade is fully tensioned as it would be for

normal operations.

7. When the wheels are coplanar and even with each

other, place a mark on each wheel where you held

the straightedge. This assures repeated accuracy

every time you adjust your wheels.

Note: When wheels are properly coplanar, the blade

may not be centered on the crown of the wheel, but

it will be balanced.

8. Secure the wheel covers and re-install the table

before re-connecting the bandsaw to power.

9. Make sure that the blade is tracking properly (refer

to Page 14).

Figure 63. Measuring the distance the

wheel is out of adjustment.