-52-

Model W1706 (Mfg. Since 8/10)

SERVICE

Troubleshooting

This section covers the most common problems and corrections with this type of

machine. WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!

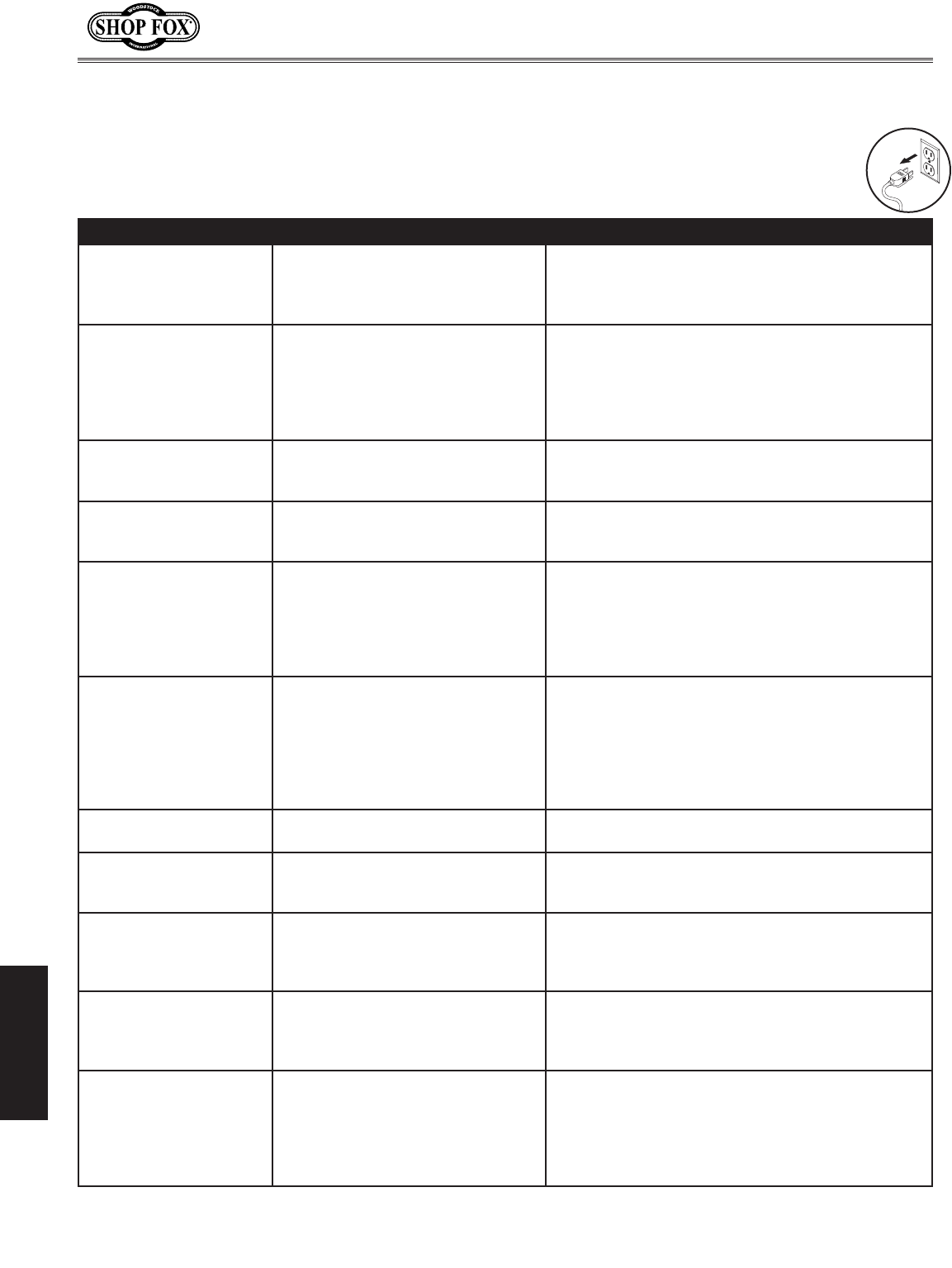

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Motor will not start. 1. Low voltage.

2. Open circuit in motor or loose

connections.

3. Faulty start capacitor.

1. Check power supply for proper voltage.

2. Inspect all lead connections on motor and magnetic

switch for loose or open connections.

3. Replace start capacitor.

Fuses or circuit breakers

trip open.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit breakers

in power supply.

1. Inspect cord or plug for damaged insulation and

shorted wires and replace extension cord.

2. Inspect all connections on motor for loose or

shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

Motor overheats. 1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Reduce load on motor.

2. Clean motor to provide normal air circulation.

Motor fails to develop full

power.

1. Power line overloaded with other

electrical devices.

2. Low power from the power source.

1. Reduce load on power line.

2. Request a power check from the power company.

Motor stalls (resulting in

blown fuses or tripped

circuit).

1. Short circuit in motor of loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers

in power line.

4. Motor overloaded.

1. Inspect connections on motor for loose or shorted

terminals or worn insulation.

2. Correct the low voltage conditions.

3. Install correct fuses or circuit breaker.

4. Reduce load on motor.

Machine slows when

operating.

1. Excessive feed rate.

2. Dull blade.

3. Incorrect blade for operation.

4. Binding the blade when cutting

curves.

5. Workpiece wet.

1. Reduce feed rate.

2. Sharpen/replace blade.

3. Use correct blade for workpiece.

4. Make more relief cuts; use correct blade width for

operation.

5. If moisture content is higher than 20%, sticker and

allow to dry.

Blade does not run evenly

on wheels or runs off.

1. Tracking is not properly adjusted.

2. Wheels are not coplanar.

1. Properly adjust blade tracking (see Page 14).

2. Adjust wheel alignment (see Page 47).

Blade slows when cutting;

machine makes a squealing

noise upon startup.

1. Belt loose.

2. Belt excessively worn.

1. Adjust belt tension (see Page 43).

2. Replace belt (see Page 44).

Ticking sound when

bandsaw is running.

1. Blade weld contacting guide bear-

ings.

2. Motor fan or cover damaged.

3. Damaged blade; bent teeth.

1. Use a stone to smooth blade weld.

2. Replace.

3. Replace blade.

Blade contacting table

insert.

1. Excessive side pressure on blade

when cutting.

2. Table not properly adjusted.

1. Reduce side pressure on blade.

2. Properly align the table with the blade (see

Page 19).

Excessive vibration when

bandsaw is running.

1. Machine sits on floor unevenly.

2. Wheels not coplanar.

3. Tires incorrectly installed.

4. Belt worn out.

5. Bent or damaged blade.

6. Wheel(s) out of balance.

1. Adjust rubber feet; shim if necessary.

2. Adjust wheel alignment (see Page 47).

3. Check/re-install/replace.

4. Replace belt (see Page 44).

5. Replace blade (see Page 39).

6 Replace wheel(s).