12.

Assembly and adjustments

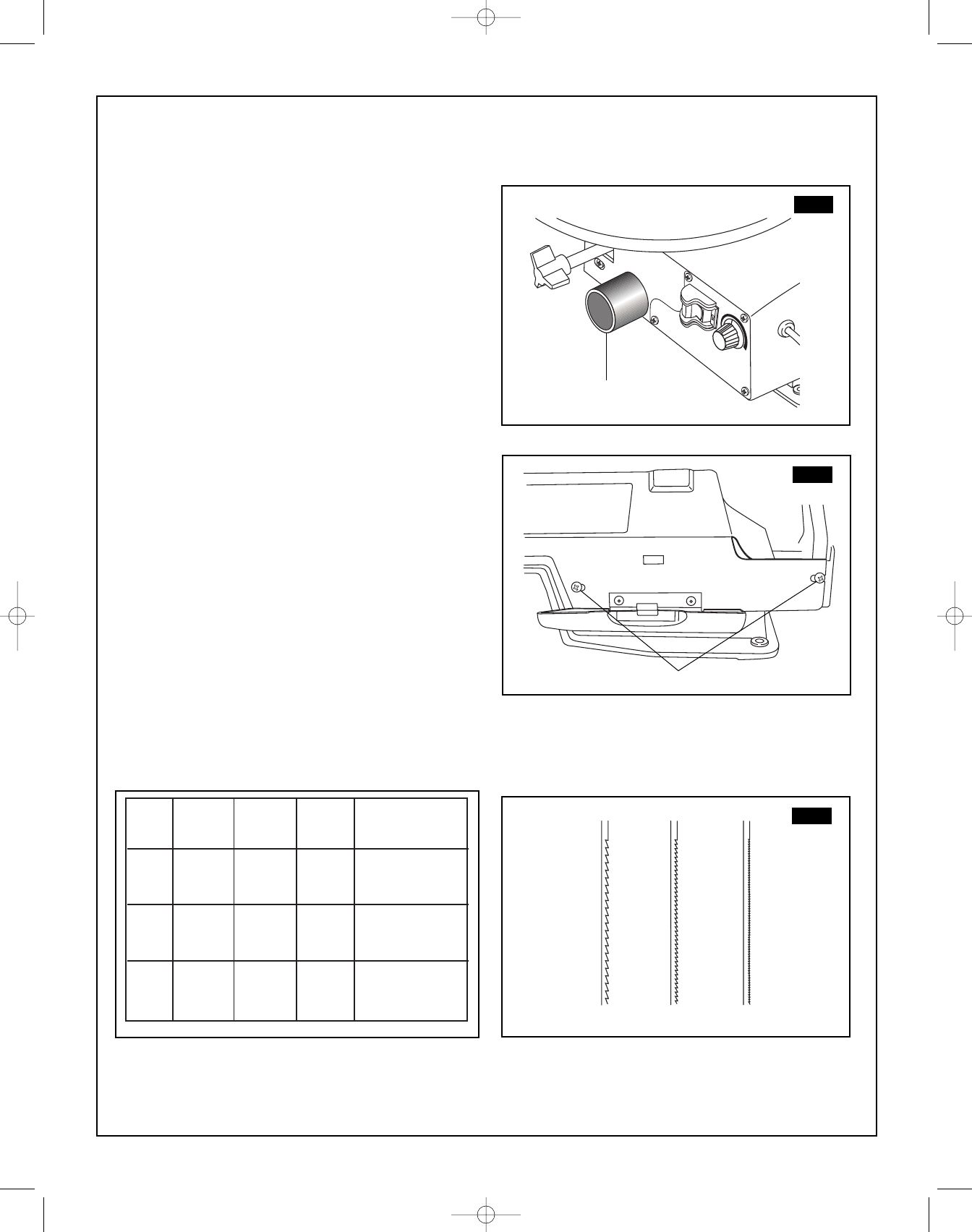

Sawdust collection port (Fig. 10 and 11)

This scroll saw allows a hose or vacuum accessory (not

provided) to be connected to the dust chute (1).

If excessive sawdust buildup occurs inside the base,

use a wet/dry vacuum cleaner or manually remove saw-

d

ust by removing the screws

(

2)

a

nd metal plate on the

left side of the saw. Reattach the metal plate and screws

before starting the saw. This will keep your saw cutting

efficiently.

Blade selection (Fig. 12)

This scroll saw accepts both both pin-end and plain-end

5" length blades, with a wide variety of blade thickness-

es and widths. The type of material and intricacies of

cutting operations will determine the number of teeth per

inch. Always select the narrowest blades for intricate

(tight radius and curves) curve cutting and the widest

blades for straight and large curve cutting operations.

The following table represents suggestions for various

materials. When purchasing blades, refer to the back of

the package for best use of blades on various materials.

Use this table as an example, but practice and your own

personal preference will be the best selection method.

When choosing a blade, use very fine, narrow blades to

scroll cut in thin wood 1/4" thick or less.

Use wider blades for thicker materials but this will

reduce the ability to cut tight curves.

Note: Thinner blades will have more possibilities for

blade deflection when cutting angles are not perpendic

-

ular to the table.

FIG. 10

1

2

FIG. 11

10 - 15 15 - 28 30 - 48

FIG. 12

Teeth/ Blade Blade Blade/

Inch Width Thickness SPM Material Cut

TPI inch inch

Medium turns on

10-15 0.110 0.018 500-1200 1/4" to 1-3/4" wood,

soft metal, hardwood

Small turns on 1/8"

15-28 0.055-0.110 0.010-0.018 800-1700 to 1-1/2" wood, soft

metal, hardwood

Non-ferrous

30-48 0.024-0.041 0.012-0.019 Varies metals/hardwoods

using very slow speeds

SM 2610957121 05-08 6/5/08 7:35 AM Page 12