For Machines Mfg. Since 8/09 Model SB1021/SB1022

-39-

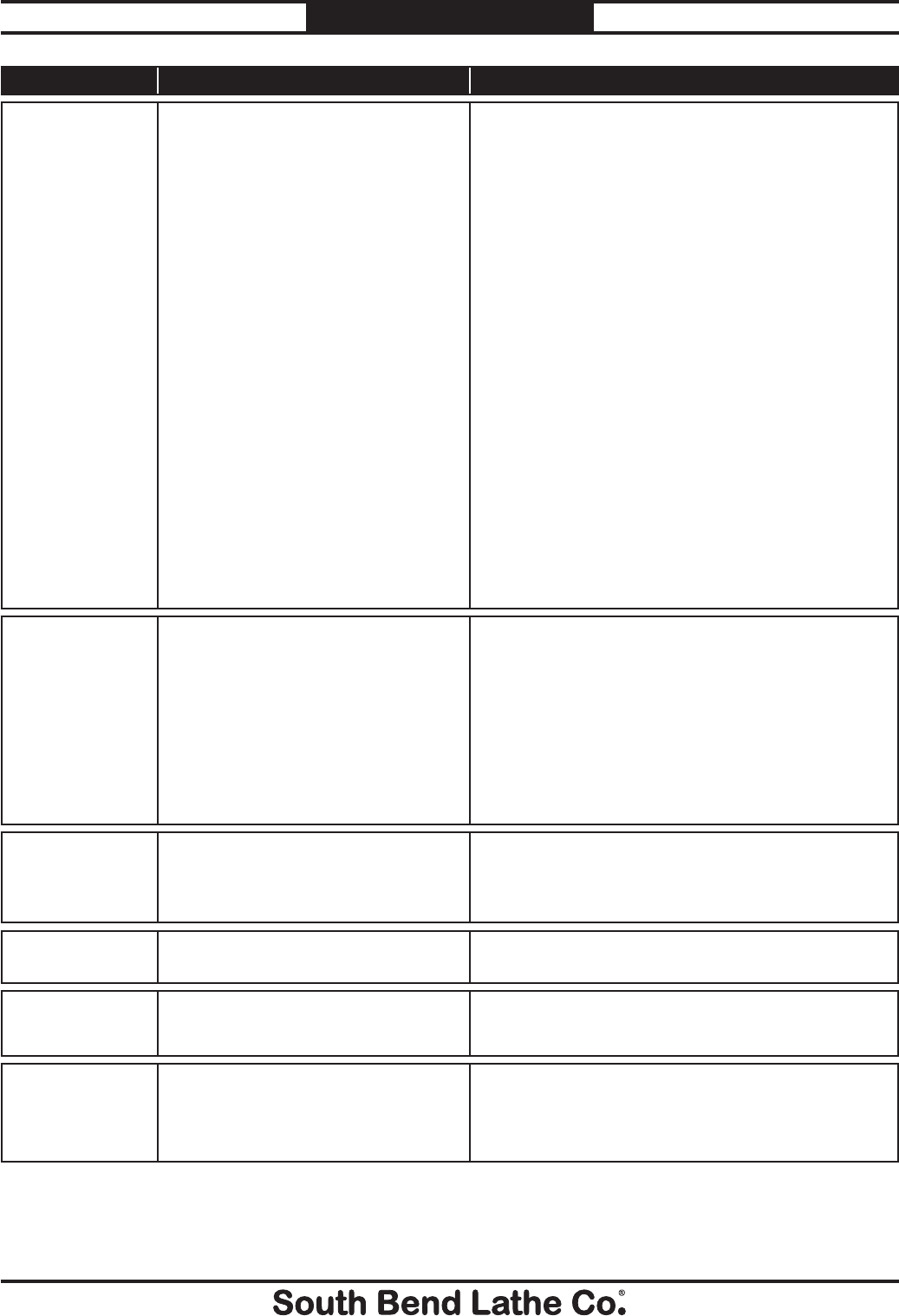

TROUBLESHOOTING

Symptom Possible Cause Possible Solution

Machine stalls

or slows when

operating.

1.

Too much pressure when feeding

workpiece.

1.

Reduce pressure when feeding workpiece.

2.

Motor is wired out of phase

(SB1022 only).

2. Swap two power incoming power leads (see Page

47).

3.

Workpiece is warped and binding

blade.

3.

Fabricate a jig for better workpiece control.

4.

Blade is not correct for material

being cut.

4.

Use the correct blade for the operation. Refer to

Blade Selection section beginning on Page 20.

5.

Belt(s) slipping.

5.

Tension/replace belt(s); ensure pulleys are aligned.

6.

Motor overheated.

6.

Let cool, clean motor, and reduce workload.

7.

Run capacitor at fault (SB1021

only).

7.

Test/repair/replace.

8.

Pulley or sprocket slipping on shaft.

8.

Replace pulley and key or set screw. Replace shaft

if worn.

9.

Motor connection wired incorrectly.

9.

Review wiring diagram on motor cover; correct wire

connections.

10.

Contactor has poor contacts.

10.

Test all legs for power, test field coil and replace if

at fault.

11.

Centrifugal switch at fault (SB1021

only).

11.

Adjust/replace centrifugal switch if available.

12.

Motor at fault.

12.

Test for shorted windings, bad bearings and repair

or replace.

Handwheel has

excessive backlash,

endplay, binds, or

is difficult to move.

1.

Leadscrew is dirty or lacks proper

lubrication.

1. Clean and lubricate the leadscrew (see Page 33).

2.

Pinion gears out of adjustment.

2.

Re-adjust pinion gears to reduce backlash (see

Page 37).

3.

Bearing or leadscrew collar is worn

or loose.

3.

Replace bearing or readjust leadscrew collar (see

Page 37).

4.

Linkage bolts, pins, and holes are

loose or worn.

4.

Replace linkage bolts, pins, and re-bush any worn

pin holes.

5.

Leadscrew or leadscrew nut worn.

5.

Replace leadscrew or leadscrew nut.

Welder is

inoperative or

welds poorly.

1.

Operator error.

1.

Use welder as outlined in operations section and

practice on scrap blades (see Page 28).

2.

Wiring or welding switch at fault.

2.

Repair wiring or replace welding switch.

3.

Welder transformer at fault.

3.

Replace welder transformer.

Cuts are not square

or the intended

angle is incorrect.

1.

Pointer or scale not calibrated or

loose table.

1.

Zero table to blade and realign scale pointers (see

Page 35). Tighten any loose fasteners.

2.

Table guide post is loose or out of

alignment.

2.

Tighten any loose hardware or lock levers. Align the

guide post (see Page 36).

Work lamp or

welding lamp does

not work

1.

Bulb, wiring, or switch at fault.

1.

Replace bulb, repair wiring, replace switch.

2.

Transformer is at fault.

2.

Replace transformer.

Grinder does not

work.

1.

Wiring or ON/OFF switch at fault

1.

Repair wiring or replace grinder switch.

2.

Motor at fault.

2.

Replace motor.