For Machines Mfg. Since 8/09 Model SB1021/SB1022

-41-

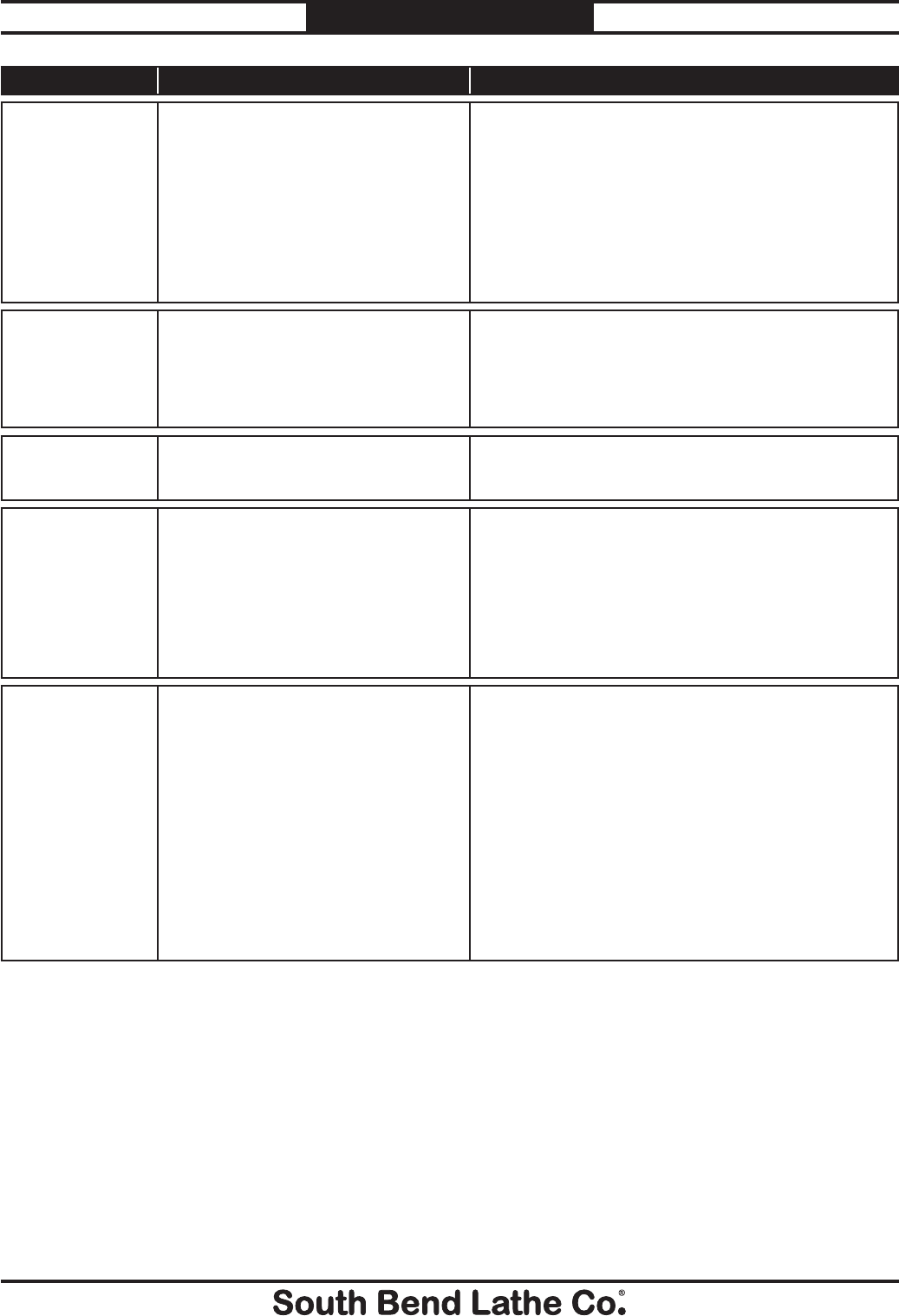

TROUBLESHOOTING

Symptom Possible Cause Possible Solution

Blade dulls

prematurely, or

metal sticking to

the blade.

1.

Blade is improperly broken in.

1.

Replace blade, and complete blade break in

procedure.

2.

The blade gullets are loading up

with chips.

2.

Use a blade that has larger gullets to carry out

material.

3.

The blade TPI is too fine for the

thick workpiece, and the teeth load

up and overheat.

3.

Use a coarser-tooth blade, adjust feed rate, adjust

blade speed, make sure the brush is working.

4.

The workpiece has hard spots,

welds, or scale.

4.

Replace the blade with a special blade for cutting

hardened materials.

Loud, repetitious

noise coming from

machine.

1.

Pulley set screws or keys are

missing or loose.

1.

Inspect keys and set screws. Replace or tighten if

necessary.

2.

Motor fan is hitting the cover.

2.

Adjust fan cover mounting position, tighten fan, or

shim fan cover.

3.

V-belts are defective.

3.

Replace V-belts.

Ticking sound

when the saw is

running.

1.

Blade weld contacting blade guides.

1.

Grind blade weld down smaller.

2.

Blade weld may be failing.

2.

Cut and reweld the blade, or replace the blade.

Blade wears on

one side or shows

overheating.

1.

The blade guides are worn or mis-

adjusted.

1.

Re-adjust or replace the blade guides.

2.

The blade support is inadequate.

2.

Tighten the blade guide as close to the workpiece as

possible.

3.

Wheels are not coplanar.

3.

Adjust wheels so they are parallel and aligned.

4.

Dull or incorrect blade.

4.

Replace blade.

5.

Blade is bell-mouthed.

5.

Install new blade.

Vibration when

operating or

cutting.

1.

Loose or damaged blade.

1.

Tighten or replace blade.

2.

Worn wheel bearing.

2.

Check/replace wheel bearing.

3.

Wheels are not coplanar.

3.

Adjust wheels so they are parallel and aligned.

4.

Wheel tires worn or incorrectly

installed.

4.

Replace or dress rubber tires.

5.

Bent or dull blade.

5.

Replace blade.

6.

Wheels out of balance.

6.

Replace wheels.

7.

Loose machine component.

7.

Tighten loose component.

8.

Belt has a high spot.

8.

Replace/adjust the V-belt.

9.

Bandsaw blade wheel is bent or out

of balance.

9.

Check and replace for bad wheel or bearing.