-50-

For Machines Mfg. Since 5/11

13" Heavy 13

®

Gearhead Lathe

OPERATION

Operating the lathe at spindle speeds higher

than 350 RPM when the high (H) gearbox

range is selected could result in gearbox

damage. Always use spindle speeds of

350 RPM or lower when using the high (H)

gearbox range.

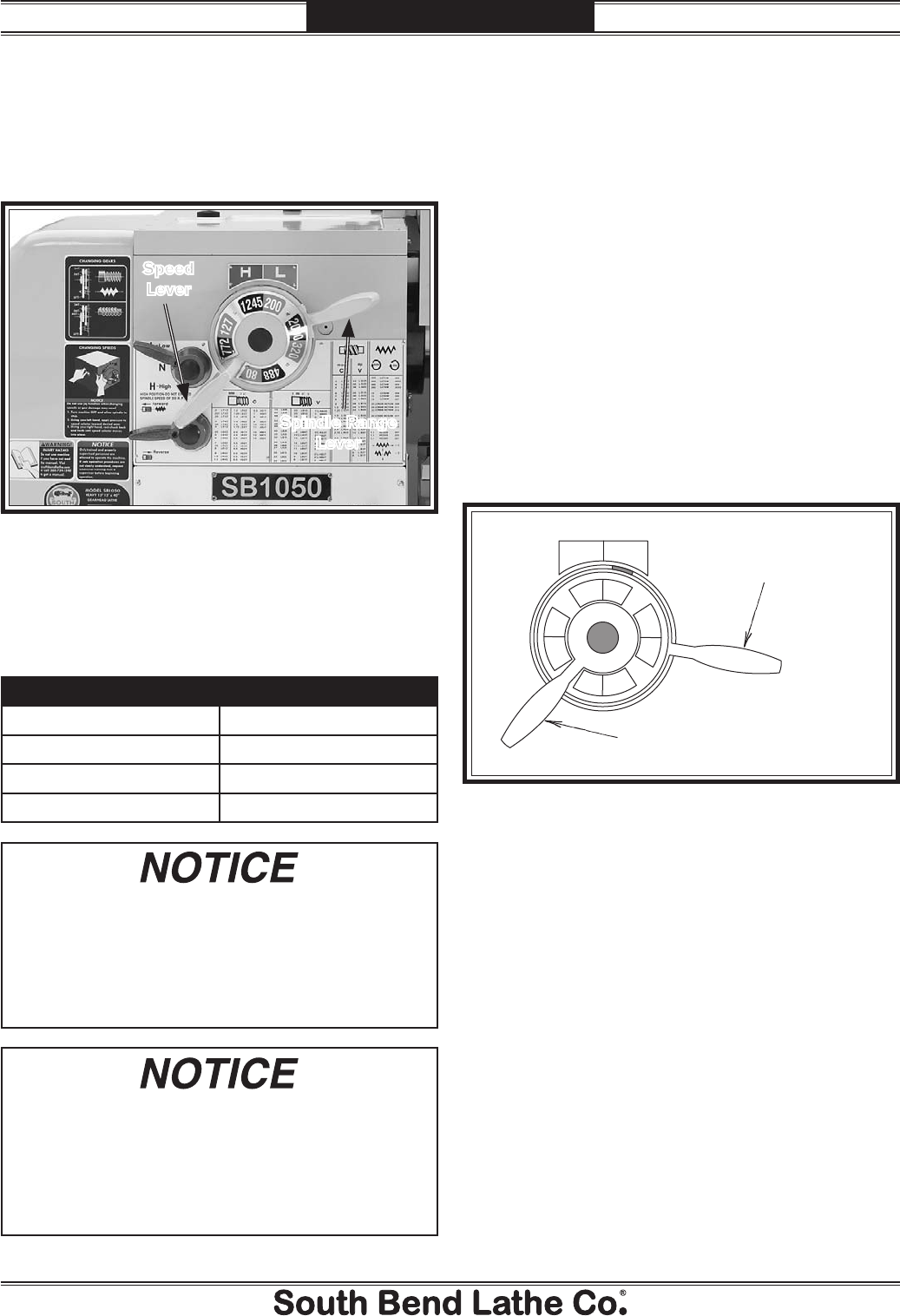

Setting Spindle Speed

Selecting one of the 8 spindle speeds available is

a combination of configuring the spindle range

lever and the spindle speed lever shown in

Figure 66.

The spindle speed and range levers control the

gear configuration in the headstock to produce

the selected spindle speed. Refer to the chart

below for the available spindle speeds available.

Low Range (RPM) High Range (RPM)

80 488

127 772

200 1245

320 2000

ALWAYS make sure the spindle is completely

stopped BEFORE using the headstock control

levers to make changes. If the spindle is

rotating when attempting to change the

spindle speed, the headstock gears will suffer

damage!

Configuration Examples

Using the controls on the lathe, follow along with

these two examples for setting the spindle speed

to gain a better understanding of this task.

Setting Spindle Speed of 200 RPM

1. Make sure the spindle is completely stopped

and the spindle lever is in the OFF (middle)

position.

2. Move the spindle range lever to the right

so that the arrow on top of its hub points

toward the L (low) label (see the illustrated

in Figure 67).

Note: If necessary, use the chuck key to rock

the spindle back-and-forth to help mesh the

gears as you move the levers.

Figure 67. Setting the spindle speed to 200 RPM.

&

*

*

*

"

$

"

"

"

%

$

"

)

)

$

#

$

)

#

$

&

'

$

"

"

:>

Spindle Range

Lever Set to LOW

Spindle Speed

Lever Set to 200 RPM

3. Move the spindle speed lever so that the 200

on its hub is also pointing at the L label.

Note: You will hear a distinctive click when the

spindle speed lever is in the correct position.

The lathe is now set for a spindle speed of 200

RPM.

Figure 66. Spindle speed controls.

Speed

Lever

Spindle Range

Lever