© SprayTECH. All rights reserved. 3

English

Table of Contents

Safety ......................................................................................... 2

Grounding Instructions ........................................................ 2

Service ....................................................................................... 2

Introduction ............................................................................... 3

Using an HVLP Spray System ................................................. 3

Setup ................................................................................... 3

Dual Filtration System ......................................................... 3

Maintenance .............................................................................. 4

Cleaning/Replacing Filters .................................................. 4

Cleaning the Air Hoses........................................................ 4

Wiring Diagram ......................................................................... 4

Troubleshooting ....................................................................... 5

Parts List ........................................................................... 14–15

Français ..................................................................................... 6

Español.................................................................................... 10

Warranty .................................................................................. 16

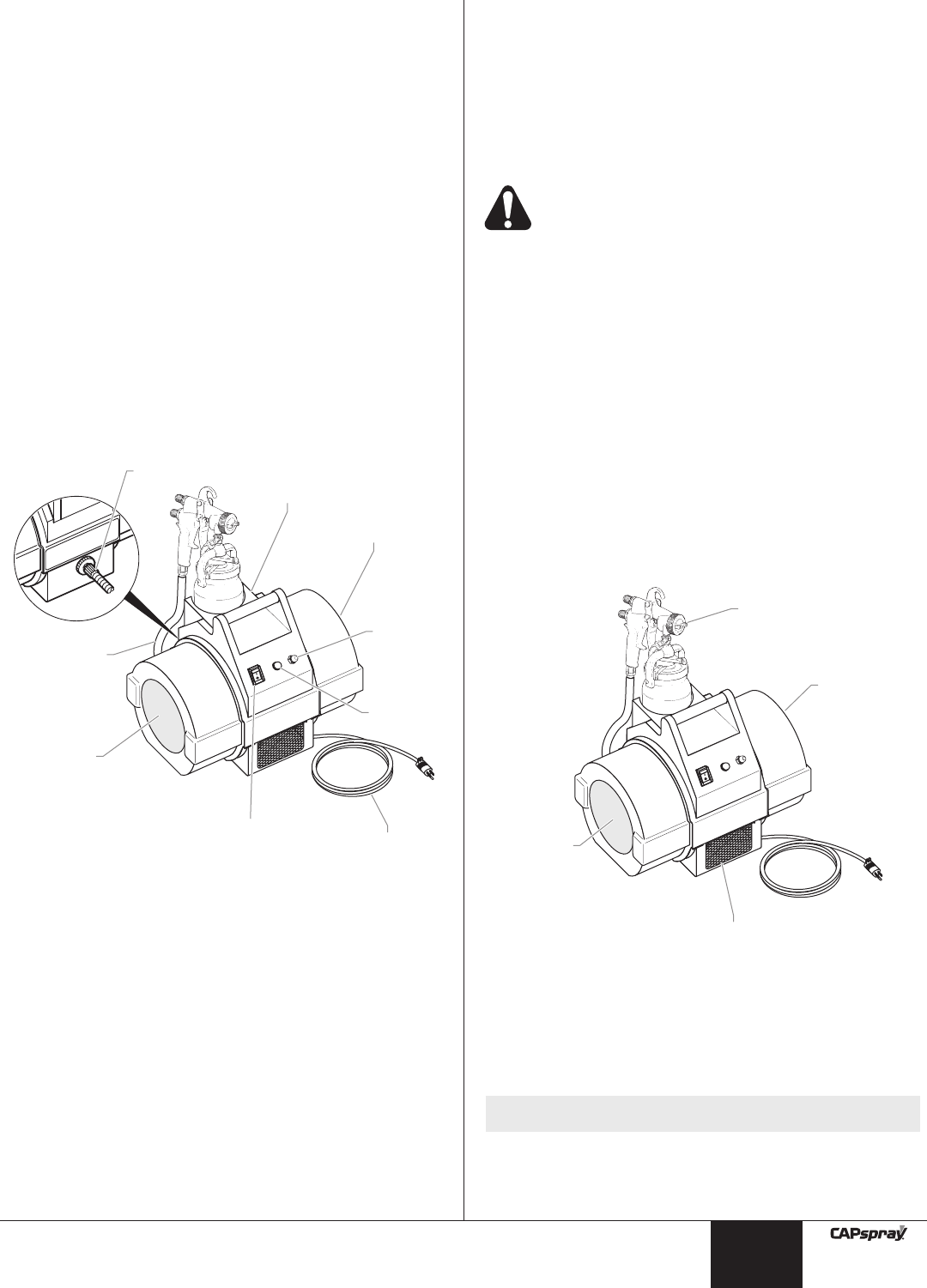

Introduction

This High Volume/Low Pressure (HVLP) spray system is

designed for applying coatings to surfaces that can be sprayed

faster than brushing or rolling and are too small for traditional

airless sprayers. Components of this system include a power

switch, a power cord, a lter warning light, a circuit breaker

switch, a dual ltration system, a cup holder, an air hose, and an

air outlet.

Cup Holder

Circuit

Breaker

Switch

Filter

Warning

Light

Power Switch

Power Cord

Filter

Filter (in end

of filter can)

Air Hose

Air Outlet

With this HVLP spray system, you can achieve the highest quality

professional nish possible with little or no preparation or setup

time. Please review all the information contained in this manual

before operating the system.

Using an HVLP Spray System

Refer to the following information to operate and understand your

HVLP spray system.

Setup

Use the following procedure to set up your HVLP spray system

for operation.

1. Plug the turbine power cord into a grounded, 3-slot

receptacle.

Keep the turbine at the maximum possible distance

from the spray area to safeguard against explosion

or fire that may be caused by sparking electrical

parts.

2. Prepare your spray gun for operation. Refer to your spray

gun manual for material preparation, setup, and spraying

information.

3. Attach the air hose to the air outlet on the turbine.

4. Attach the air hose to the air inlet on your spray gun.

5. Turn on the turbine and begin spraying.

Dual Filtration System

The turbine has two different air lters— one for atomizing air

and one for cooling air. The atomizing air lter is a two-stage,

ne mesh lter designed to trap particles that may damage your

nish. The atomizing air is discharged through the nozzle of the

spray gun where it atomizes the coating material. The cooling air

lter is a coarse mesh lter designed to allow the proper amount

of air ow through the turbine for cooling purposes. Cooling air

is exhausted through the cooling air discharge on the front of the

turbine.

Cooling Air Discharge

Cooling Air

Intake

Atomizing Air

Intake

Atomizing Air

Discharge

Filter Warning System

The lter warning system on your turbine consists of a red lter

warning light on the front control panel and an air ow switch

inside the turbine. When the air ow switch does not detect the

appropriate amount of air owing through the turbine, the lter

warning light will come on to indicate that it is time to clean or

change the lters.

NOTE: Thelterwarningsystemdoesnotshutdownthe

turbine.

IMPORTANT: Clean filters regularly. Clogged filters can

cause excessive heat and possibly damage the turbine.

Uncontrolled Copy