36

GB

Starting operation

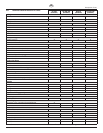

4.2 High-pressure hose, spray gun and separating

oil

1. Screw the high-pressure hose (g. 12, item 1) onto the hose

connection (2).

into the high-pressure hose.

Screw on hose whip (4).

3. Screw connection socket (5) to the spray gun (6).

4. Screw spray gun with selected tip to the high-pressure hose or

hose whip (4), depending on the model.

the model, at the hose whip to prevent coating material from

leaking.

2

1

5

6

4

1

3

6. Fill in EasyGlide (g. 13). Do not ll in too much separating

oil, i.e. ensure that no separating oil drips into the coating

material container.

Attention

EasyGlide prevents increased wear and tear to the

packings.

4.3 Gasoline engine (gas units only)

1. Fill in the supplied engine oil.

when the oil level is too low.

instructions.

2. Fill the gasoline tank.

For information on the gasoline please refer to the engine

instructions.

4.4 Connection to the mains (electric units only)

Attention

The connection must take place through a properly

earthed two-pole and earth socket outlet.

Before connecting the unit to the mains supply, make sure that the

been connected.

4.5 Flushing preserving uid during initial

start-up

1. Push locking pin (g. 14, item 1) and swivel material feed

pump to a container with suitable cleaning agent.

the left (pressure reduction) until it stops.

k

Circulation).

4. Start the engine or turn on the electric motor.

i

The direction of the rotation of the pulley must

correspond to the arrow (4) on the belt cover. If the

belt is running opposite the direction of the arrow:

Switch unit to “O” (OFF). Unplug power plug and

turn the polarity changer (5) in the power plug by

180º with a screwdriver. Plug in power plug again.

5. Move the hydraulic ball valve (6) on the material feed pump

motor.

Hydraulic oil ows to the hydraulic motor of the material feed

pump.

p spray).

8. Pull the trigger of the spray gun.

9. Spray the cleaning agent from the unit into an open collecting

container.