40

GB

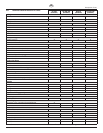

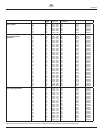

Remedy in case of faults

9.1 Gasoline engine

9.2 Electric Motor

9.3 Hydraulic motor

Type of malfunction

A. Gasoline engine does not start up

Type of malfunction

Piston rod in the material feed pump

is not moving up and down.

Type of malfunction

A. Hydraulic motor stuck in the lower

position.

B. Hydraulic motor stuck in the upper

position.

correctly in the downward stroke, but

outside of the hydraulic motor is very

hot.

hydrau lic motor becomes very

hot when stroking upward and

downward.

Possible cause

3. Gasoline cock closed.

4. Engine problem.

5. Engine defective.

Possible cause

1. Indicator light does not indicate unit

has power.

automatically because of an overload.

1. Direction of the rotation of the electric

motor is incorrect

Possible cause

pump is loose.

2. Reversing valve in the hydraulic

motor is stuck or the upper or lower

become loose.

1. Reversing valve is stuck.

2. Pressure spring on valve rod is broken.

3. Pressure spring stop on valve rod is

broken.

4. Air in the hydraulic motor.

5. Air in the material feed pump.

1. Faulty piston packing in hydraulic

motor.

2. Piston rod is broken.

faulty.

2. Packings in the material feed pump

are worn.

Measures for eliminating the malfunction

1. Fill the gasoline tank.

4. Please refer to the engine instructions.

5. Bring to the Honda service point.

Measures for eliminating the malfunction

1. Check power supply.

2. Wait 2 – 3 minutes, then turn the unit back on.

Measures for eliminating the malfunction

1. Ball valve on the material feed pump – lever position

vertical. Screw out sealing screw on hydraulic motor.

Press down reversing valve on hydraulic motor.

moves upward and then gets stuck in the lower

Vent air at low pressure during a 5 – 10 minute

endurance run. Do not let the material feed pump run

dry.

Check for leaks:

5. Ball valve on the material feed pump – lever position

vertical. Screw out sealing screw on hydraulic motor.

Press down reversing valve on hydraulic motor.

Remount sealing screw. Start unit. Prevent the material

feed pump from sucking up air.

2. Replace