GB

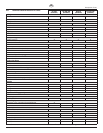

Starting operation Interruption of work

2

1

6

3

4

5

HC970E

HC970E-SSP

4.6 Taking the unit into operation with coating

material

If the unit is located on a non-conductive surface

(e.g. a wood oor), earth the unit with an earthing

cable.

1. Push locking pin (g. 14, item 1) and swivel material feed

pump into the coating material container.

the left (pressure reduction) until it stops.

k

Circulation).

4. Start the engine or turn on the electric motor.

i

The direction of the rotation of the pulley must

correspond to the arrow (4) on the belt cover. If the

belt is running opposite the direction of the arrow:

Switch unit to “O” (OFF). Unplug power plug and

turn the polarity changer (5) in the power plug by

180º with a screwdriver. Plug in power plug again.

5. Move the hydraulic ball valve (6) on the material feed pump

motor.

Hydraulic oil ows to the hydraulic motor of the material feed

pump.

p spray).

8. Pull the trigger of the spray gun, then set the desired

operating pressure by means of the pressure control knob (2).

5. Spraying technique

the spray pattern will be uneven. Carry out the spray movement with

surface to be coated in order to minimize the paint mist.

i

If very sharp edges result or if there are streaks in the

spray jet – increase the operating pressure or dilute

the coating material.

6. Handling the high-pressure hose

piston pumps.

Danger of injury through leaking high-pressure

hose. Replace any damaged high-pressure hose

immediately.

Never repair defective high-pressure hoses yourself!

bends and folds: the smallest bending radius is about 20 cm.

Do not drive over the high-pressure hose. Protect against sharp

objects and edges.

avoided by using a Wagner spray gun with a swivel joint and a hose

system.

i

When using the high-pressure hose while working

on scaolding, it is best to always guide the hose

along the outside of the scaolding.

The risk of damage rises with the age of the high-

pressure hose. Wagner recommends replacing high-

pressure hoses after 6 years.

Use only WAGNER original-high-pressure hoses in

order to ensure functionality, safety and durability.

7. Interruption of work

1. Move the hydraulic ball valve on the material feed pump to its

horzontal position (closed).

Flow of hydraulic oil to hydraulic motor of material feed pump

is interrupted.

k

Circulation).

4. Pull the trigger of the spray gun in order to release the

pressure from the high-pressure hose and spray gun.

5. Secure the spray gun, refer to the operating manual of the

spray gun.

6. If a standard tip is to be cleaned, see page 43, point 11.2.

If a non-standard tip is installed, proceed according to the

relevant operating manual.

immerse it in the corresponding cleaning agent.

Attention

If fast-drying or two-component coating material is

used, ensure that the unit is rinsed with a suitable

cleaning agent within the processing time.