16

Operation

This sander is intended for dry sanding of

metals. Do not use lubricants.

Do not sand or polish

magnesium; it may create a fire hazard. Also,

do not sand very small or very thin

workpieces that cannot be safely controlled.

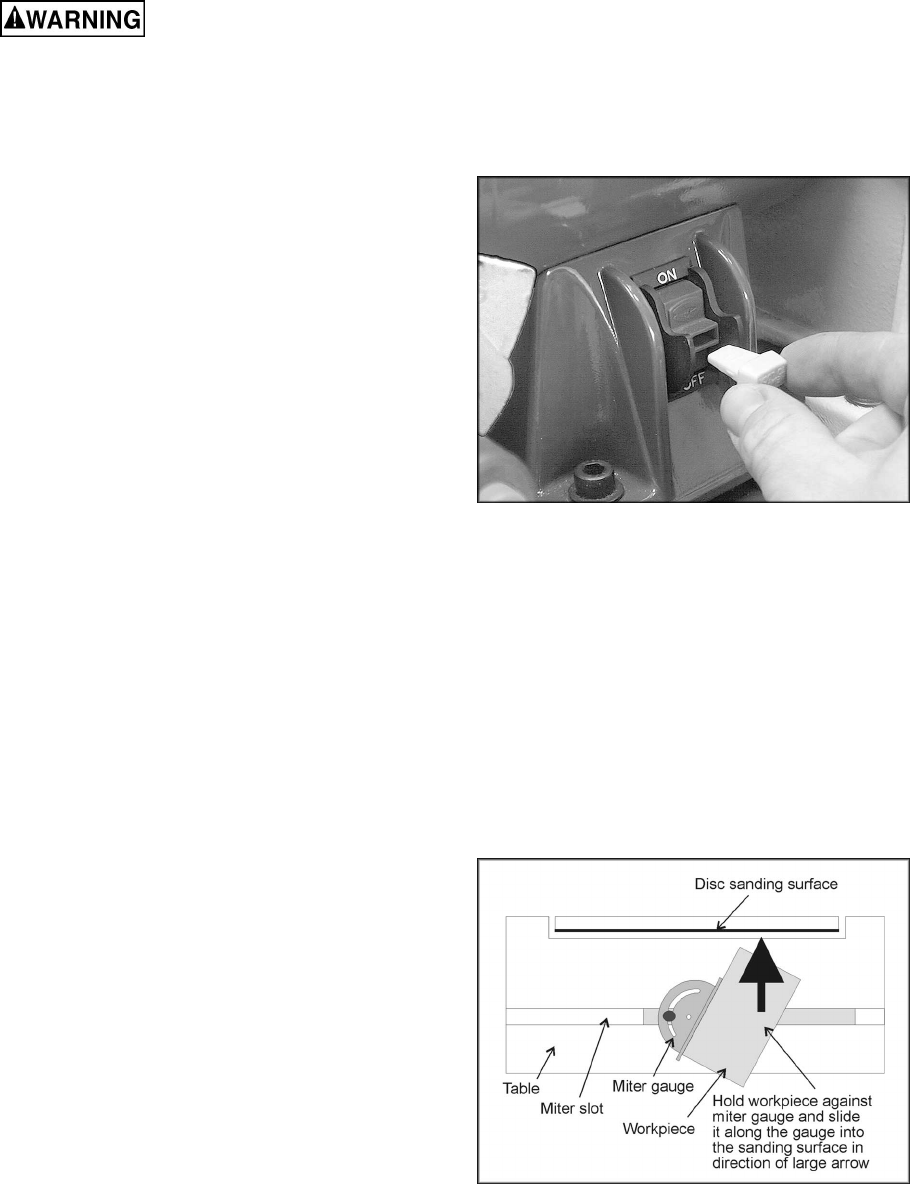

Starting and Stopping the Sander

The on/off switch is located on the side of the

motor housing. Move the switch upward to the

ON position to start the sander. Move the switch

downward to the OFF position to stop the

sander.

When the sander is not being used, the switch

can be locked in OFF position to prevent

unauthorized use. Pull out the locking tab and

store in a safe place. See Figure 16. The switch

will not operate with the locking tab removed.

To use the sander, re-insert the locking tab.

Belt and Disc Movement

When the machine is turned on, the abrasive

belt should be moving downward and the disc

rotating clockwise. The motor is wired at the

factory for correct rotation.

The workpiece should not contact the disc or

belt during start-up. Before sanding, always

allow the motor to come up to operating speed,

then observe the disc for wobble, runout, or any

unbalanced condition. If the disc is not operating

accurately and smoothly, stop the motor and

make repairs before atempting any sanding

operations.

Always sand on the side of the abrasive disc

that rotates downward. Sanding on the upward

rotation side can cause the workpiece to catch

and fly out of your hands.

The table must be a maximum of 1/16” away

from the abrasive disc or belt.

Typical Operations

When sanding a compound angle you should

check the accuracy of your setup by sanding a

piece of scrap material before doing any finish

sanding on the actual workpiece.

Figure 17 demonstrates a basic method of

operation using the miter gauge and disc table:

1. Set the angle you wish to sand using the

scale on the miter gauge.

Figure 16

Figure 17