Adjustments

Blade Tracking Adjustment

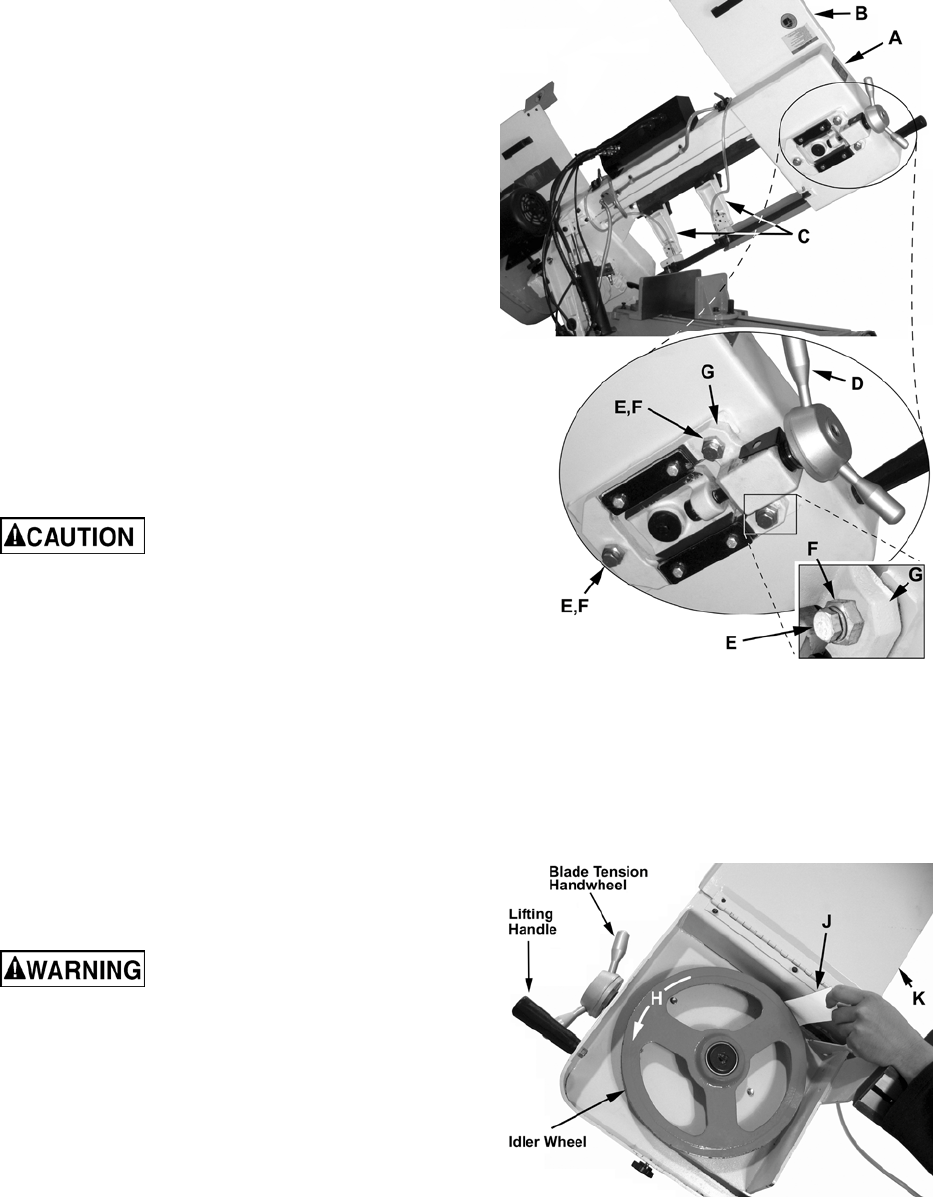

Refer to Figures 13 and 14.

Blade tracking has been set and tested at the

factory. Adjustment is rarely required when the blade

is used properly or if the blade is correctly welded.

If adjustment is needed:

1. Using the blade tension handwheel (D), make

sure the blade is properly tensioned.

Note: Blade tensioning is described in the

Changing Blades section on page 18).

Keep proper tension at all times.

2. Raise the saw head (A) as shown.

3. Open the wheel guards (B).

4. Remove both of the blade-guide bearing bracket

assemblies (C).

5. Loosen three hex locking screws (E) in the head

weldment (G).

While performing the following,

keep the blade from rubbing excessively on the

shoulder of the wheel. Excessive rubbing will

damage the wheel and/or the blade.

6. Start the saw. Turn the adjustment screws (F) to

tilt the idler wheel (Figure 14) until the blade is

touching the shoulder of the idler wheel.

Note: As a general rule, make the same adjustment

to the two adjustment screws on the right (F). The

single adjustment on the left is independent.

7. Next, turn the adjustment screws (F) so the

blade starts to move away from the shoulder of

the wheel – then immediately turn the

adjustment screws in the other direction so the

blade stops – then moves slowly toward the

shoulder.

Keep fingers clear of the blade

and wheel to avoid injury.

8. Turn the adjustment screws (F) to stop the

motion of the blade on the wheel as it gets

closer to the wheel shoulder.

Put a 6-inch length of paper (J, Fig. 14) between

the blade and the wheel as shown (the saw is

still turned on). The paper should not be cut as it

passes between the wheel shoulder and the

blade.

9. Turn the adjustment screws (F) slightly.

Figure 13

Figure 14