8

The mechanism also has adjustment screws

that enable the saw blade to “track” evenly on

the blade wheels. The adjustment screws

change the angle of the driven blade wheel shaft

so the wheels are aligned. Tracking adjustments

are generally made after the saw blade is

changed but may be required periodically due to

wear over time.

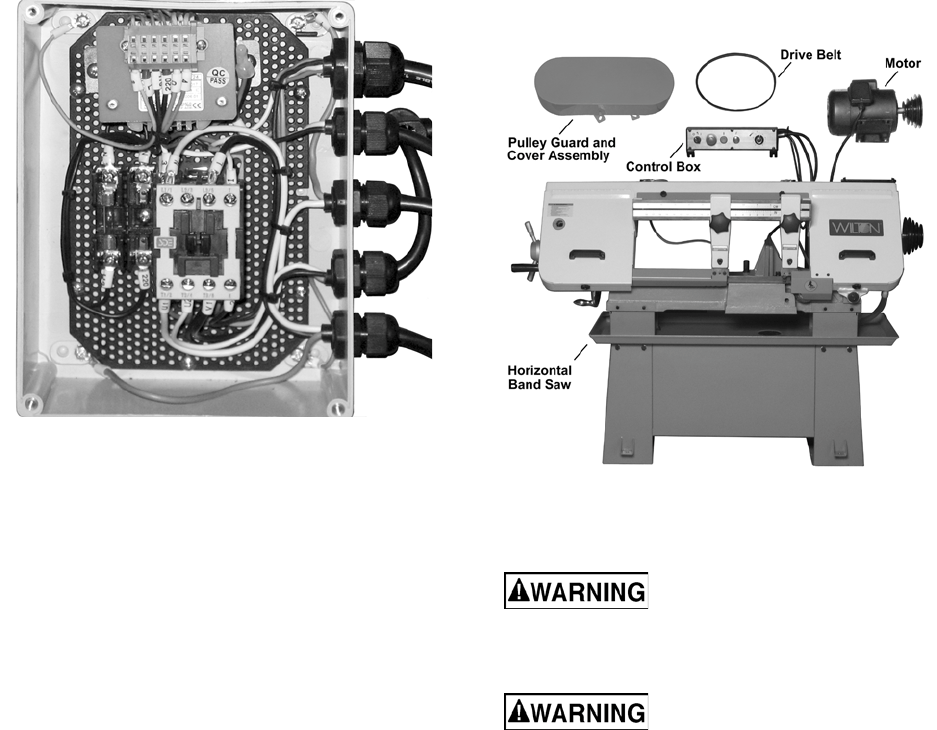

An electrical enclosure is attached to the leg

panel on the right side of the machine. The

enclosure contains the switches and fuses

required for operation and protection of the drive

motor (Figure 3).

Figure 3

Work Stop

A work stop is provided with the machine to

allow cutting multiple pieces of identical length

(refer to Figure 12). The stop consists of a rod

onto which is installed a stop bracket, a tapered

stop, a clamping knob and a locking handle. The

rod is installed in a bore in the front of the saw

bed. The stop bracket is positioned on the rod

with the tapered stop toward the end of the

workpiece. The bracket is moved in or out on the

rod to establish the length of the workpiece.

Control Panel

The control panel is mounted on the top of the

saw head. Refer to the Controls and Indicators

section (page 9) for a description of the controls.

Unpacking and Assembly

Machine Setup

The cut-off saw has been pre-adjusted at the

factory and several test pieces have been cut to

verify cutting accuracy.

Remove the saw from the shipping skid; discard

any hold-down devices. Place the saw on the

shop floor; secure the saw to the floor using

mounting anchors secured through four holes in

the machine base. If the saw will be used to cut

long pieces of stock, allow plenty of room for the

length of the stock.

Minimal assembly is required (see to Fig. 4),

consisting of mounting the control box, motor,

pulley guard/cover assembly and motor drive

belt. The mounting hardware is already in place

on the saw head. Loosen or remove the

hardware, placing the components (listed above)

in place and secure. For the drive belt, refer to

the Drive Belt section on page 19.

Figure 4

Electrical Connection

Electrical connection must

be made by a licensed electrician. The wiring

methods and practices must comply with

local electrical codes.

The machine uses high

voltage electrical power that poses a

significant risk of serious injury or death if

proper precautions are not observed

Connect the machine to the electrical power

branch circuit (refer to the Wiring section on

page 31). Observe the following guidelines when

connecting the saw to the power source.

1. Make sure the saw is disconnected from

the electrical power branch circuit (trip the

required circuit breakers or remove the

required fuses).