9

2. Place a warning placard or tag on the

service panel to prevent accidental

electrical shock.

3. When installing the motor power cord into a

receptacle, make sure the plug is

compatible with the receptacle.

4. When using hard-wired connections,

connect the wires as shown in the Wiring

Data section.

5. Install the fuses or reset the breakers.

Check operation of the saw.

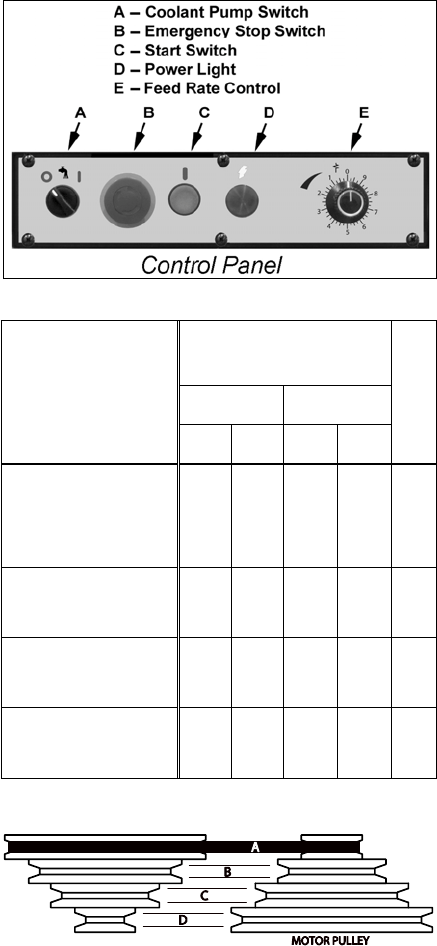

Controls and Indicators

Control Panel

The operating controls for the cut-off saw are

located on the control panel (Figure 5) and

consist of the following controls and indicators:

Coolant Pump Switch – turns the coolant pump

on and off.

Emergency Stop Switch – press to stop the drive

motor. Note: A micro switch also stops the

motor when the workpiece is cut and the saw

head is completely down.

Start Switch – press to start the drive motor. The

saw head must be in the raised position.

Power Light – indicates that machine is plugged

in and the outlet circuit breaker is turned on. The

machine does not need to be running for the

power light to be on.

Feed Rate Control – this knob is used to set the

amount of downward force that is applied to the

saw blade. The feed rate is proportional to the

opening of the valve. When set to zero, the saw

head is locked in the raised position. Increasing

the valve opening (counterclockwise adjustment)

increases the feed rate; decreasing the valve

opening (clockwise adjustment) reduces the

feed rate.

Blade Speeds

The Model 7015 horizontal cut-off bandsaw has

four blade speeds. The different speeds are

obtained by changing the position of the motor

drive V-belt on step pulleys. Change blade

speeds as follows:

1. Disconnect the electrical power from the

cut-off saw branch circuit to prevent

accidental motor start-up

2. Set the saw head at the fully down position.

3. Remove the knob from the drive belt cover.

Swing cover out and downward to expose

the V-belt and pulleys.

4. Loosen the drive motor locking handle.

Pivot the motor inward to slacken the belt.

5. Select the speed using the placard on the

cover. Put the V-belt in the pulley grooves

of the pulley for the desired speed. Refer to

Figure 6 for belt locations and the speeds

available.

Figure 5

Belt Speed

60Hz 50Hz

Material to Be Cut

fpm mpm fpm mpm

Belt Position

Tool Steel, Stainless

Steel, Alloy Steel,

Phosphor Bronze, Hard

Bonze, Hard Cast Iron,

Malleable Iron

82 25 68 21

A

Mild Steel, Soft Cast Iron,

Medium Hard Brass,

Medium Hard Bronze

132 40 110 33

B

Soft Brasses and

Bronzes, Hard Aluminum,

Plastics

170 51 142 43

C

Plastics, Soft and Medium

Aluminum, Wood, Other

Light Materials

235 71 196 60

D

Note: Belt position A shown below

Figure 6

6. Pivot the motor outward to tighten the

V-belt. Tighten the locking handle.

7. Check V-belt tension by pushing the V-belt

firmly downward; press down about midway

between the pulleys. When properly tight-

ened, the V-belt should depress no more

than the width of the belt.