12

WARNING

Maintenance performed by

unauthorized personnel may

result in misplacing of the internal components

which could cause serious hazard. We

recommend that all compressor service be performed

by a BOSCH factory service center or authorized

BOSCH service station.

Your air compressor requires periodic maintenance

according to the maintenance schedule outlined on

the next page, in order to keep your compressor in

peak condition.

Use a soapy water solution to inspect compressor

for leaks. If leaks are found in the compressor pump,

air tanks or tubing, replace compressor immediately.

Never attempt repair leaks, weld or make

modications to the air tank or other uid conning

parts as there is a risk of bursting.

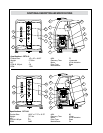

To check the air lter, unscrew the air lter from the

compressor and visually inspect. If the lter appears

to be clogged, replace the lter. After inspection screw

the air lter back on the compressor (See Fig. 9).

serVICe

CHANGING OIL (See Fig. 10):

1. Make sure the pump is cool to avoid burn risk.

2. Take out the oil dipstick (A).

3. Prepare a suitable container to capture the oil from

the crankcase.

4. Remove crankcase drain plug (B) and allow used

oil to drain in the container.

5. Replace drain plug.

6. Return oil to recycling center or dispose of in

accordance with local regulations.

7. Rell crankcase with fresh oil. Fill oil until it reads

to maximum level of oil dipstick.

8. Replace oil dipstick (A).

Contact your BOSCH service center for instructions

and user replaceable parts. For all other repairs

contact your BOSCH service center.

drAInInG tAnks

1. Place the compressor on a level surface.

WARNING

Ensure that the compressor is on

a level surface. If compressor is not

level, water will not drain from tanks causing

corrosion, which may cause the tanks to burst.

2. If pressure is greater than 20 psi, use safety release

valve to reduce tank pressure.

WARNING

Do not open drain valve with

pressure greater than 20 psi in

tanks. Such precautionary measures reduce the risk

of injury.

3. Ensure that no personnel are in the drain discharge

area in front of compressor.

WARNING

Do not direct air stream at people

or animals. High pressure air can

propel dust and debris at high speed. Compressor air

from the compressor can contain water, oil, metal

particles, or other contaminants which can cause

serious injury.

4. Turn drain valve on control panel 90°

counterclockwise. When empty, close valve.

oPerAtIon

mAIntenAnCe

Fig. 9

Fig. 10

MAX

MIN

(B)

(A)