8

www.chpower.com

Operating Instructions and Parts Manual

WS4369 and WS4469

Welding Guidelines

(Continued)

COMMONLY USED ELECTRODES

1. E-6011 Deep Penetrating

• The strong arc force and rapid

solidification of the metal makes

vertical and overhead welding

easier with this rod.

• Where time does not permit rust,

scale or paint removal, this rod

penetrates rapidly and easily.

• Acceptable for AC or DC welding

current (reverse polarity).

2. E-6013 General Purpose

• All position, smooth deposit rod

with low spatter.

• For all mild steel and general

purpose work.

• Acceptable for AC or DC welding

current (straight or reverse

polarity).

3. E-7014 Iron Powder

• A general purpose "drag" rod for

all positions.

• Ideal for situations where fit

between metal pieces is poor.

• The iron powder in the flux coating

combines with the filler rod to

make a smooth deposit with very

little spatter.

• Ideal for ornamental work.

• Acceptable for AC or DC welding

current (reverse polarity).

4. E-7018 Low Hydrogen

• An all position high strength

electrode designed to produce low

hydrogen content combined with

excellent mechanical properties.

• Acceptable for AC or DC welding

current (reverse polarity).

CURRENT

The correct current involves the

adjustment of the welding machine

to the required amperage setting.

Current represents the actual flow of

electricity and is regulated by a knob on

the welder. The current used depends

on the size (diameter) and type of

electrode used, position of the weld,

and the thickness of the work piece.

Consult specifications listed on the

electrode package or generalized chart

in the Operation section. Excessive

current burns through light metals,

and the weld bead is flat and porous or

the bead undercuts the work piece (See

Figure 8). The bead appears high and

irregular if the current is too low.

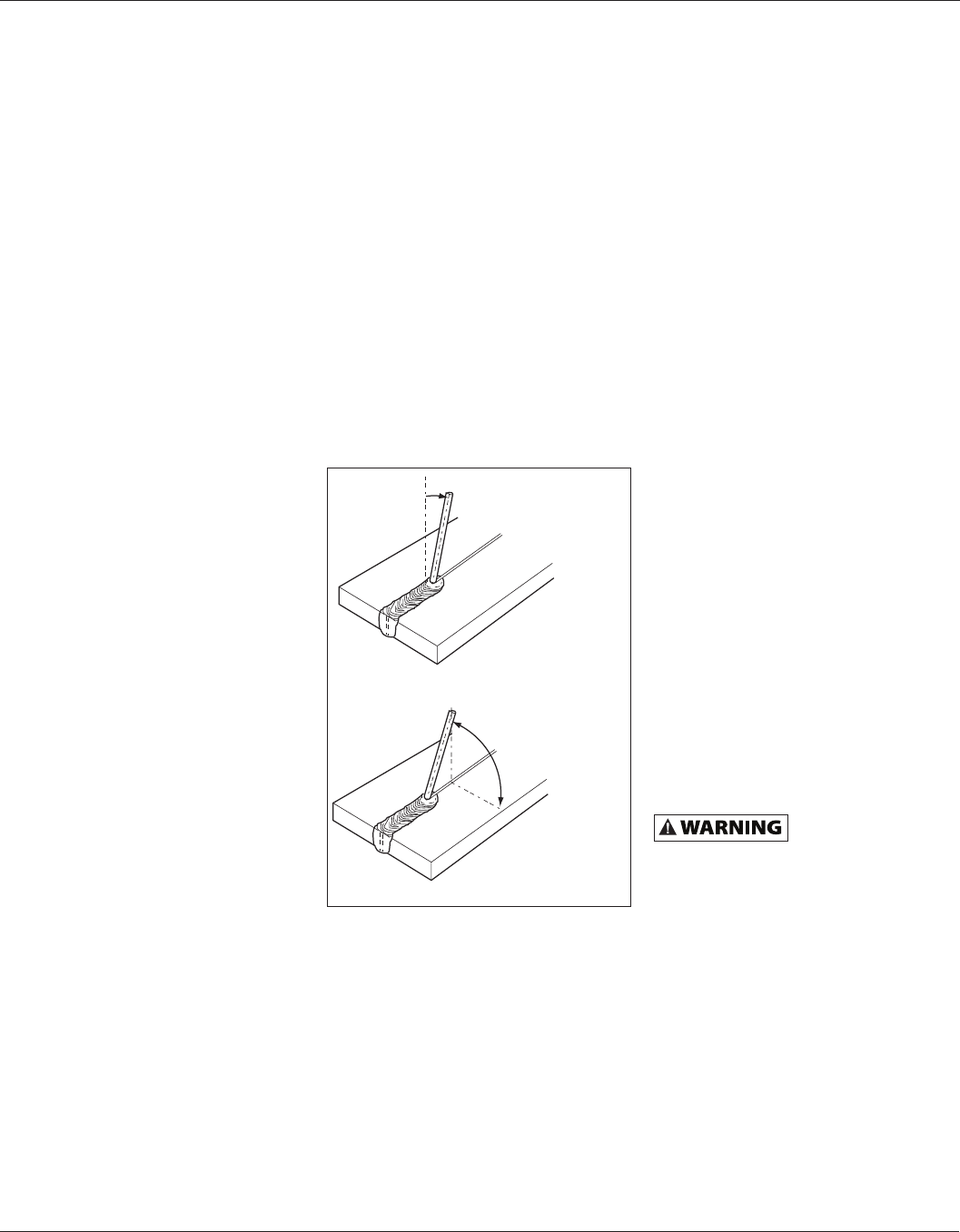

WELD ANGLE

Weld angle is the angle at which the

electrode is held during the welding

process. Using the correct angle

ensures proper penetration and bead

formation. As different welding

positions and weld joints become

necessary, electrode angle becomes

an increasingly important factor in

obtaining a satisfactory weld. Electrode

angle involves two positions - travel

angle and work angle (See Figure 7).

Travel angle is the angle in the line

of welding and may vary from 5º to

45º from the vertical, depending on

welding conditions.

Work angle is the angle from

horizontal, measured at right angles to

the line of welding.

For most applications, a 45º travel

angle and 45º work angle is sufficient.

For specific applications, consult an arc

welding handbook.

NOTE: Right handed welders should

weld from left to right. Left handed

welders should weld from right to left.

The electrode should always point into

the weld puddle as shown.

ARC LENGTH

Arc length is the distance from the

work piece to the tip of the electrode,

the distance which the arc must travel.

A proper arc length is essential to

generate the heat needed for welding

(See Figure 8). An arc that is too long

produces an unstable arc, reduces

penetration, increases spatter, and

causes flat and wide beads. Too short

an arc does not create enough heat to

melt the work piece, the electrode has

a tendency to stick, penetration will be

poor, and uneven beads with irregular

ripples result. A proper arc should be

no longer then the diameter of the rod.

The sound of a proper arc is a steady,

crisp sizzle, similar to bacon frying.

TRAVEL SPEED

The travel speed is the rate at which

the electrode is moved across the weld

area. Factors such as diameter and

type of electrode, amperage, position,

and work piece material thickness all

effect the speed of travel necessary for

completing a good weld (See Figure 8).

When the speed is too fast, the bead is

narrow and bead ripples are pointed

as shown. When the speed is to slow,

the weld metal piles up and the bead is

high and wide.

SLAG REMOVAL

Wear ANSI approved

safety glasses (ANSI

Standard Z87.1) and protective clothing

when removing slag. Hot, flying debris

can cause personal injury to anyone in

the area.

After completing the weld, wait for the

welded sections to cool. A protective

coating called slag now covers the weld

bead which prevents contaminants in

the air from reacting with the molten

metal. Once the weld cools to the point

that it is no longer glowing red, the slag

can be removed. Removal is done with

a chipping hammer. Lightly tap the slag

with the hammer and break it loose

from the weld bead. The final clean-up

is done with a wire brush. When making

multiple weld passes, remove the slag

before each pass.

5º - 45º

Travel Angle

Work Angle

Figure 7 - Weld Angle

Work Angle

Travel Angle