Model WT5000

7

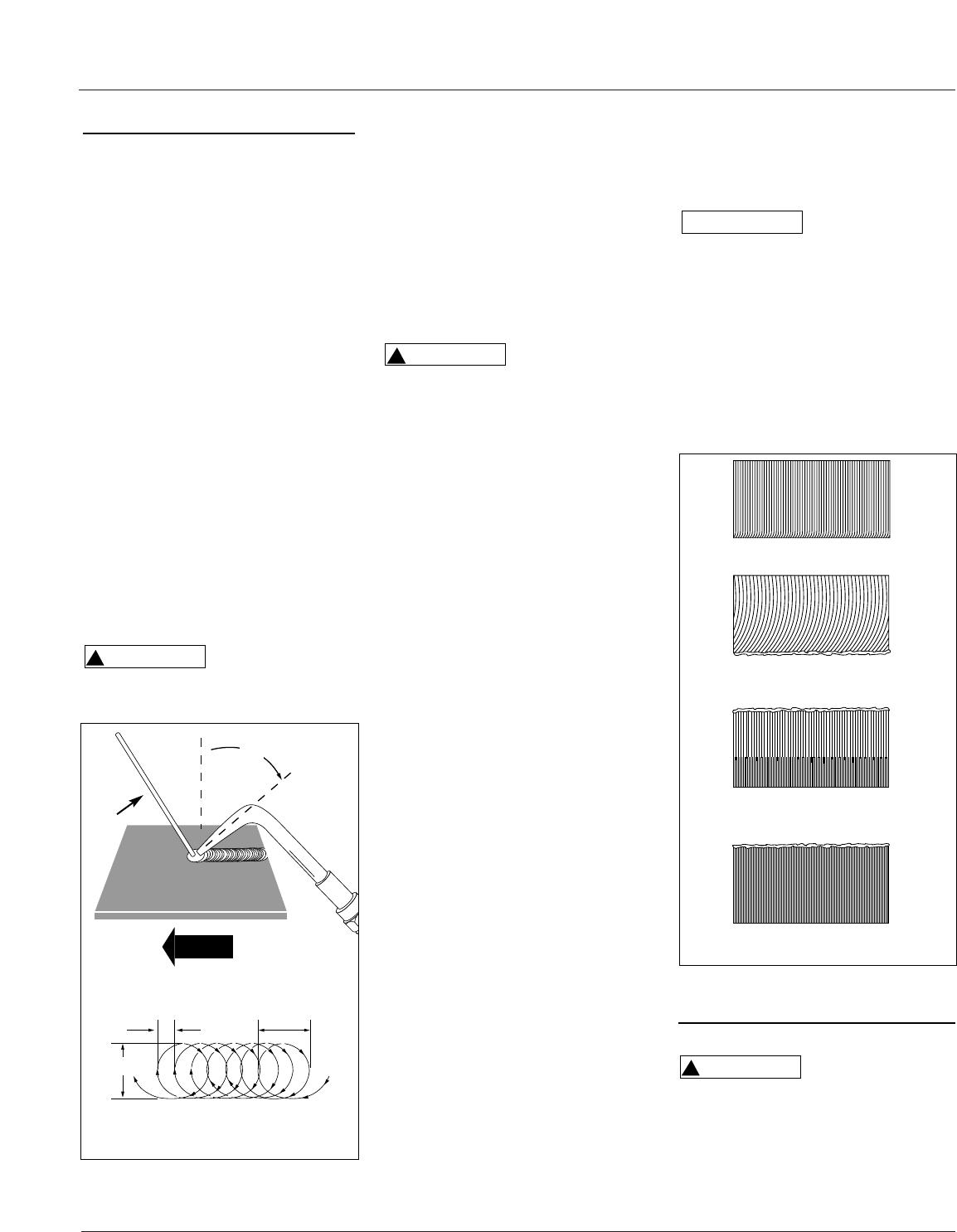

Figure 17 - Correct Cutting Speed

Welding Guidelines

Gas Welding

Gas welding is a method of joining

similar metals by melting with oxy-fuel

flame and allowing the two parts to fuse

together. The use of a filler rod is

recommended in most cases. The filler

rod should match the material being

welded with a diameter equal to the

thickness of the workpiece.

Clean all metal surfaces prior to welding.

Any oil, grease, rust, scale, paint or other

impurities must be removed before

welding.

Before attempting to weld final product,

practice on scrap material.

Begin by holding the torch tip

approximately 1/8” above the metal at a

45˚ angle to the surface. Rotate the

flame in a circular motion on the surface

you are welding. The metal will puddle

and flow together. If the puddle does

not form or is shallow, the tip size is too

small. If the metal splatters from the

puddle, the tip size is too large.

Never use oxygen

to blow off work or

clothing as spark can ignite oxygen

saturated clothing.

!

WARNING

Gas Brazing

Brazing heats the base metals to

temperatures above 700˚F, but below

their melting points. A single or multi-

flame tip may be used. A filler rod bonds

the metals together. Flux is required to

prepare metal for joining. Most metals

can be joined by brazing, however, the

proper filler rod and flux must be used.

Surfaces must be absolutely clean to

ensure sound brazed joints.

Perform all

brazing processes

in a well-ventilated area. Toxic fumes

may be generated by the brazing process.

Refer to the Material Safety Data Sheet

(MSDS) for the brazing rod.

1. If the rod is not flux coated, heat the

tip of the rod and dip into flux. The

flux will adhere to the heated rod.

2. Preheat the metal surface to a dull

red color. Only the outer flame, not

the inner cone, should be applied to

the surface. A porous deposit will

result if surface is too hot.

3. Touch the fluxed rod to the heated

metal. Allow some flux to melt and

react with the base metal.

4. Melt off small amounts of fluxed rod

as you braze. If the rod flows freely

and “tins” (adheres to the heated

base metal), the correct temperature

has been reached. Maintain this

temperature by continually moving

the flame over the metal.

5. Continue to dip the rod into the flux.

Add sufficient rod to the base metal

to build up the bead.

Flame Cutting

Flame cutting is a simple process that can

be quickly mastered. Only steel can be

cut using the flame method. Aluminum,

brass, stainless steel and other porous

metals do not burn in a manner that

allows flame cutting.

1. Light the torch as described in

Operation instructions.

2. Direct the preheat flame to the spot

where cutting is to start. Hold the

inner cone of the heating flame

approximately 1/16” above the

surface. Preheat the metal to a bright

cherry red.

!

CAUTION

3. Depress the cutting oxygen lever

slowly and completely to begin the

cutting action.

4. When the cut begins, move the torch

in the direction of cut.

Moving the torch

too slowly allows

the cut to fuse together. Moving too

quickly will not preheat the metal and

the cut will be lost.

5. Continue to depress the oxygen lever

past the final edge of the metal for a

good cut.

6. Shut down torch following shut

down instructions.

7. Compare cut edge with Figure 17 to

correct subsequent cuts.

NOTICE

Figure 16 - Proper Welding Angle

45˚

Filler

Rod

A. Correct

B. Travel speed too fast

C. Travel speed too slow

D. Preheat too hot

Advance per oval

about 1/16”

About 1/4”

Start

About 1/4”

www.chpower.com

Maintenance

CHECK VALVES

Always use

reverse flow check

valves with this equipment. They reduce

the possibility of mixing gases in the

hoses and regulators. These gases can

explode in the hoses, regulators or

cylinders, resulting in serious injury to

the operator. Test reverse flow check

valves routinely to assure correct

operation.

!

WARNING