Page 20 For technical questions, please call 1-800-444-3353. SKU 68885

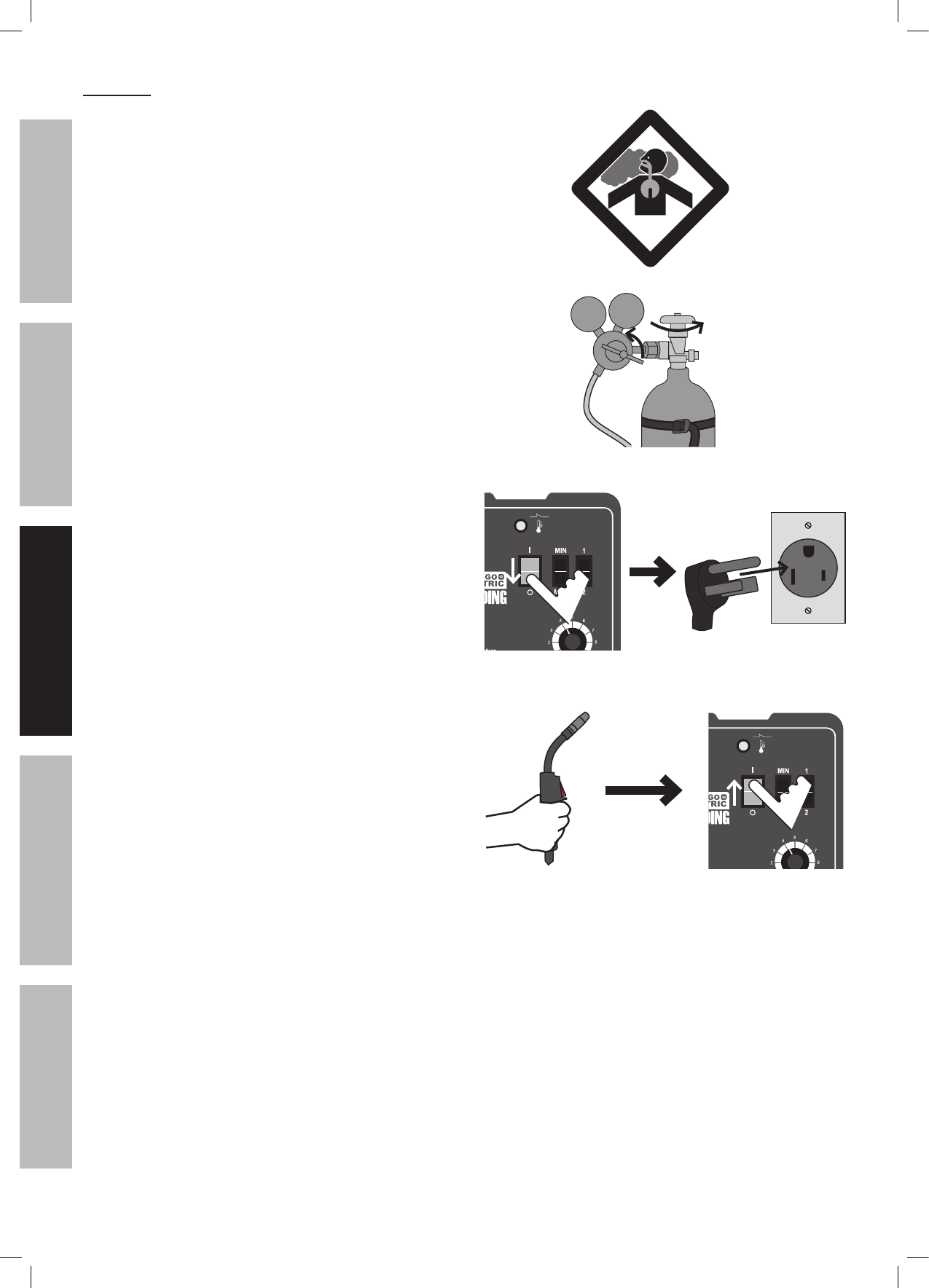

DANGER! TO PREVENT DEATH

FROM ASPHYXIATION:

Do not open gas without proper ventilation. Fix gas

leaks immediately.

Shielding gas can displace air and cause rapid loss of

consciousness and death.

Shielding gas without carbon dioxide can be even

more hazardous,

because asphyxiation can start

without feeling shortness of breath.

5. Gas shielded, solid-core wire only:

Open gas tank valve and adjust regulator/

flowmeter to flow rate indicated on chart.

6. Flip the Power Switch to the OFF position, then plug

the Welder into a dedicated, 240 V~ receptacle that

matches the plug.

The circuit must be equipped with delayed

action type circuit breaker or fuses.

7. Hold the Torch, without touching the Trigger, with the

wire and tip clearly out of the way of any grounded

objects.

Then, turn the Power Switch ON.

MIG 170

WIRE FEED WELDER

ITEM 68885

WIRE FEED SPEED

20A

240V~

Wire

.023″-.035″

(Tip and roller change required)

Capacity 22 Ga. – 1/4″ Steel Plate

Material

Types

Mild Steel and Stainless Steel

(Not for welding Aluminum.)

I

O

MIG 170

WIRE FEED WELDER

ITEM 68885

WIRE FEED SPEED

20A

240V~

Wire

.023″-.035″

(Tip and roller change required)

Capacity 22 Ga. – 1/4″ Steel Plate

Material

Types

Mild Steel and Stainless Steel

(Not for welding Aluminum.)

I

O

HOLD

TORCH

CLEAR

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP