LUBRICATION

The saw motor bearings have been packed at the factory

with proper lubricant and require no additional lubrication.

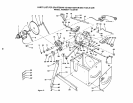

1. Lay the saw on its LEFT SIDE.

2. Clean the following parts with Craftsman Gum and

Pitch Remover; BEVEL GEARS, ELEVATION WORM

AND TEETH, TILT WORM AND TEETH.

Lubricate these parts and other bearing points indicated,

with SAE No. 20 or No. 30 engine oil.

The following parts should be oiled occasionally with SAE

No. 20 or No. 30 engine oil.

Bearing points in guard assembly, miter gauge and rip fence.

GUARD 'm _:

_ MITER GUAGE

_lk BEARING POINTS

-/ ..... _-_v,'_/ TILT WORM AND TEETH WORM AND TEETH

I I II I

RECOMMENDED ACCESSORIES

IN CANADA, SEE YOUR LOCAL SIMPSONS-SEARS STORE

OR CATALOG FOR ACCESSORY SELECTION AND NUMBERS.

ITEM CAT. NO. ITEM CAT. NO.

Retractable Caster Set ............ 9-22201 - 9-22209

7 In. Molding Head Set ...................... 9-3217

7 In. Molding Head Set ...................... 9-3218

7 In. Molding Head ......................... 9-3214

Molding/Dedo Insert for 7 in.

Dia. Molding or Dado Head ................. 9-29995

Work Light ............................... 9-2480

Work Light ............................... 9-2481

7 In. Dia. Adjustable Dado Head .............. 9-3263

7 In. Dia. Dado Head ....................... 9-3257

Blade Stabilizers ........................... 9-4952

Sanding Wheel ........................... 9-22723

Miter-Gauge Stop Rods ..................... 9-29924

Miter-Gauge Hold-Down Clamp .............. 9-29928

Hold-Down Set ............................ 9-3230

Taper Jig ................................. 9-3233

Universal Jig .............................. 9-3231

Power Tool Know How Handbook

Table Saws ............................... 9-2918

The above recommended accessories 'are current and were

available at the time this manual was printed.

27