Always use a contact tip stamped with the

same diameter as the wire it will be used

with.

Note: Due to inherent variances in flux-cored

welding wire, it may be necessary to use a

contact tip one size larger than your flux core

wire if wire jams occur.

.

If the wire burns back into the tip, remove

the tip from the gun and clean the hole

running through it with an oxygen-acety-

lene torch tip cleaner or tip drill.

.

Over time, the hole in the contact tip will

become worn by the wire passing

through it. The more worn this hole

becomes, the less efficient is the transfer

of welding current to the wire and eventu-

ally arc breakage and difficult arc starting

will result. Replace contact tips when

signs of wear become apparent.

MAINTAINING THE NOZZLE

The nozzle directs the shielding gas to the

weld puddle, determines the size of the

shielding area, and prevents the electrically

hot contact tip from contacting the work

piece.

CAUTION \.

KEEP THE NOZZLE CLEAN! During the

welding process, spatter and slag will build

up inside the nozzle and must be cleaned

out periodically. Failure to clean and/or

replace the nozzle in a timely fashion WILL

CAUSE DAMAGE TO THE FRONT-END OF

THE GUN ASSEMBLY.

For best results, coat the inside of a new, or

freshly cleaned nozzle with anti stick spray

or gel.

1. Stop welding and clean any accumulated

slag or spatter from the nozzle every 5 to

10 minutes of welding time.

2. When welding overhead, if any molten

metal drips from the weld puddle and

falls into the nozzle, STOP WELDING

IMMEDIATELY and clean the nozzle.

3. If the slag cannot be thoroughly cleaned

from the nozzle, REPLACE THE

NOZZLE!

Failure to keep the nozzle adequately

cleaned can result in the following

problems:

22

A SHORTED nozzle results when spatter

buildup bridges the insulation in the nozzle,

allowing welding current to flow through it as

well as the contact tip. When shorted, a

nozzle will steal welding current from the

wire whenever it contacts the grounded work

piece. This causes erratic welds and reduced

penetration. In addition, a shorted nozzle

overheats the end of the gun, which can

DAMAGE the front-end of the gun.

A RESTRICTED nozzle is created when

enough slag builds up in the nozzle to affect

the direction, concentration, and/or rate of

the shielding gas flow. This problem can

cause porous, brittle welds and reduce

penetration.

TESTING FOR A SHORTED NOZZLE

Arcing between the nozzle and the work

piece ALWAYS means the nozzle is shorted,

but this can be hard to detect through the

lens of a welding helmet. The following

testing method is another way to tell if a

nozzle is shorted.

With the welder unplugged from the ac

power source, touch the probes of an

ohmmeter or continuity tester to the end of

the contact tip and the outside of the nozzle.

If there is any continuity at all, the nozzle IS

shorted. Clean or replace as needed.

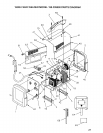

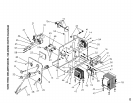

REPLACE A GUN LINER

When installing a new gun liner, care must be

taken not to kink or otherwise damage the gun

liner. See Figure 21 for the drive assembly

and Figure 22 for the gun assembly.

1. Turn OFF welder POWER SWITCH and

unplug welder from power supply.

2. Open the welder side panel.

3. Loosen the tension arm and lift it up off

the drive roller.

4. Turn the wire spool counter-clockwise (be

sure to hold onto the wire itself while

turning the spool or the wire will unspool

itself when it becomes free of the gun

liner), and remove wire from gun

assembly.

5. Lay gun cable and gun handle straight

out in front of unit.

6. Remove gun liner holding clamp by

removing two self tapping screws and

two bolts with nuts.