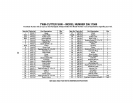

LUBRICATING INSTRUCTIONS

(See Figure C)

The blades of your Twin Cutter saw are

equippedwith"dry cut teeth that under

normal cuttingconditionsdo not need to

be lubricated.However,in extremecutting

conditions,suchas whenyou are sawing

into aluminum,copper, stainless steel and

cast Iron, the wax lubricating device must

be used.

1. Insert wax lubricating stick into wax

lubricating device.

2. Turn feeder wheel to apply lubricant to "

blade. A 1/4turn should provide adequate lubrication.

CUTTING INSTRUCTIONS cont.

Cutting Shaped Plates

up to 1116-in.thick (See Fig. 10)

1. When cuttingshaped metal plate

ALWAYS supportthe plate evenlyon

both sides and in the middlewith

support blocks. Thiswillkeep itfrom

flexing when cutting.This shouldbe

done, whether you'reusing a clamping

table, or using adjustable clamps on a

flat work table.

Fig. 10 1

S_ck

PLUNGE CUT'rING (See Figure 11)

1. Raise the retractable guardinto the

open positionwith yourleft hand,

2. Use the thumbof your left hand to hold

the guard in theopen positionwhile

grippingthe saw'sassist handle.

3. Turn on the saw and plungetheblades

into the material to be cut.

4. Push the saw forward to complete

the cut.

5. Turn off saw, allow blades to stop

completely, then remove saw from

workpiece.

6. Clean out the corners of the cut with a hand saw or sabre saw, depending

on project.

NOTE: When cutting building materials, blades must be kept clean with a tar and

pitch blade cleaning solvent

16