This saw has been lubricated at the factory prior to

shipment. Following extended use, you should inspect

and lubricate the following areas to assure smooth

operation.

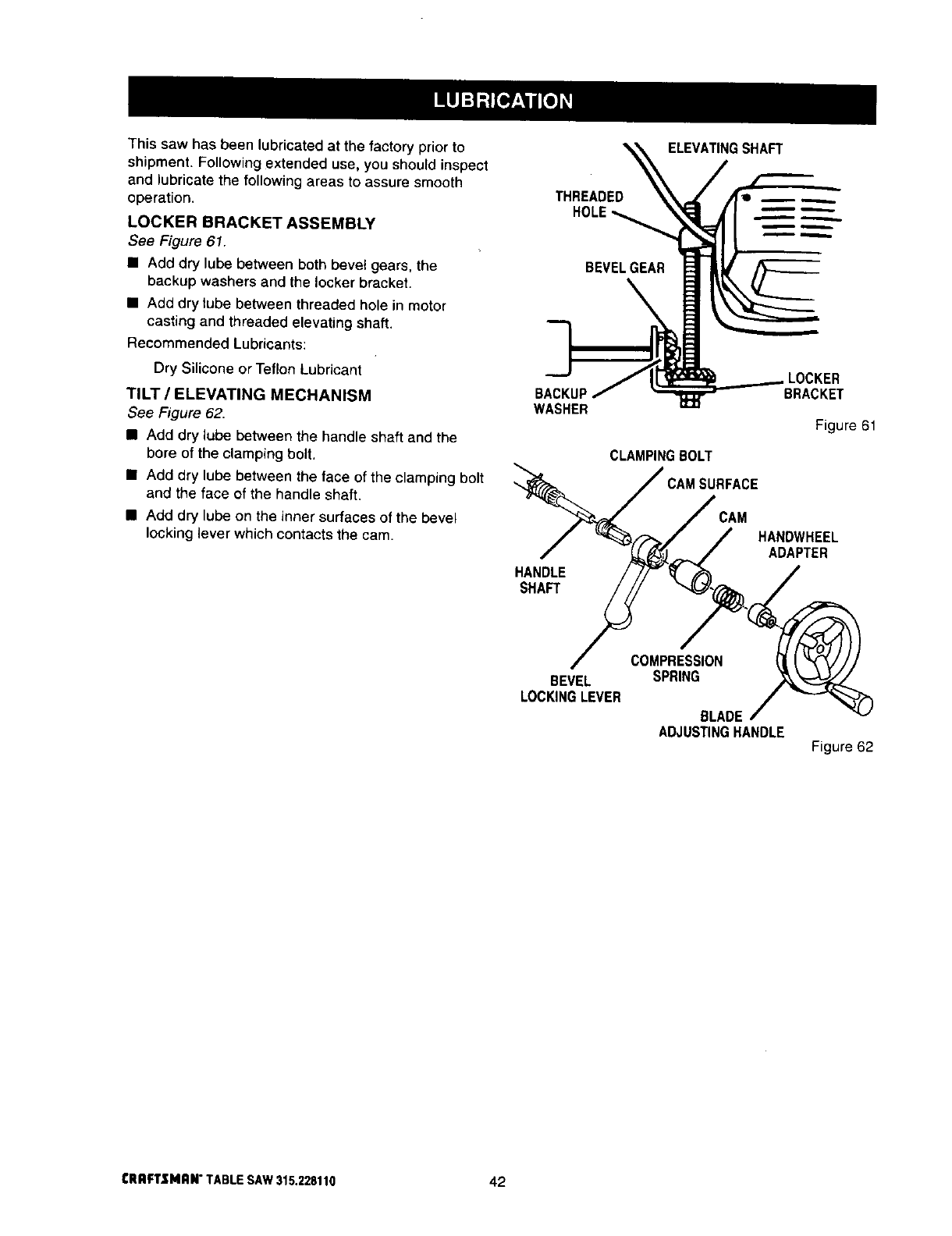

LOCKER BRACKET ASSEMBLY

See Figure 61.

• Adddry lube between both bevel gears, the

backup washers and the locker bracket.

• Add dry tube between threaded hole in motor

casting and threaded elevating shaft.

Recommended Lubricants:

Dry Silicone or Teflon Lubricant

TILT / ELEVATING MECHANISM

See Figure 62.

• Add dry lube between the handle shaft and the

bore of the clamping bolt.

• Add dry tube between the face of the clamping bolt

and the face of the handle shaft.

• Add dry lube on the inner surfaces of the bevel

locking lever which contacts the cam.

ELEVATINGSHAFT

THREADED

HOLE

BEVEL GEAR

BACKUP

WASHER

CLAMPINGBOLT

BRACKET

Figure 61

HANDLE

SHAFT

HANDWHEEL

ADAPTER

BEVEL

LOCKINGLEVER

COMPRESSION

SPRING

BLADE

ADJUSTING HANDLE

Figure 62

CRRFTSHRN"TABLESAW315.228110 42