USQ Models

5

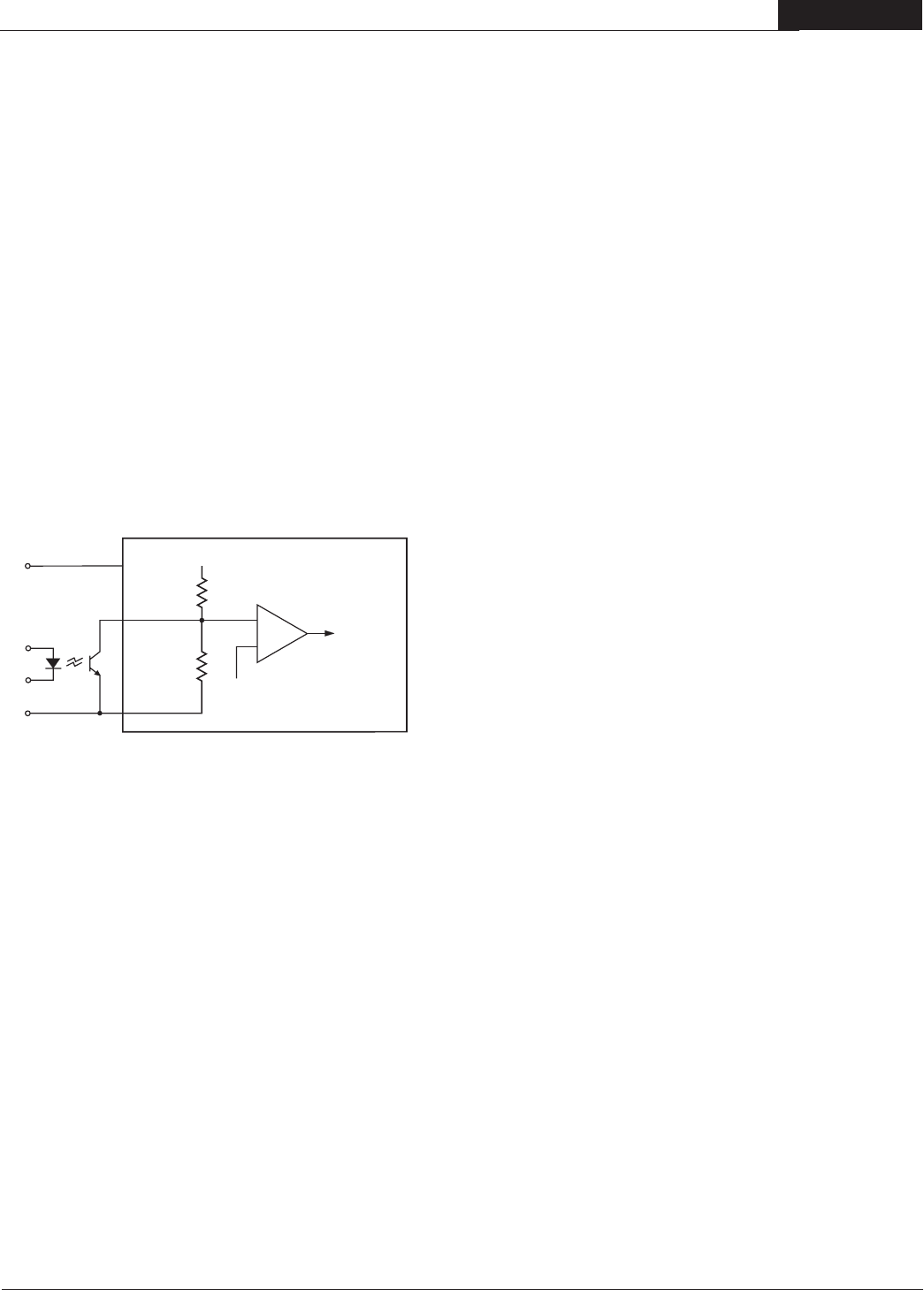

On/Off Control

The primary-side, Remote On/Off Control function (pin 2) can be specified to

operate with either positive or negative polarity. Positive-polarity devices ("P"

suffix) are enabled when pin 2 is left open or is pulled high (+2.5-5V applied

with respect to –Input, pin 1, IIN < 150µA typical). Positive-polarity devices are

disabled when pin 2 is pulled low (0-0.8V with respect to –Input, I

IN < 800µA.

Negative-polarity devices are off when pin 2 is high/open and on when pin 2

is pulled low. See Figure 4.

Dynamic control of the remote on/off function is best accomplished with

a mechanical relay or an open-collector/open-drain drive circuit (optically

isolated if appropriate). The drive circuit should be able to sink appropriate

current (see Performance Specifications) when activated and withstand

appropriate voltage when deactivated.

Current Limiting

When power demands from the output falls within the current limit inception

range for the rated output current, the DC/DC converter will go into a current

limiting mode. In this condition the output voltage will decrease propor

-

tionately with increases in output current, thereby maintaining a somewhat

constant power dissipation. This is commonly referred to as power limiting.

Current limit inception is defined as the point where the full-power output

voltage falls below the specified tolerance. If the load current being drawn

from the converter is significant enough, the unit will go into a short circuit

condition. See “Short Circuit Condition.”

Short Circuit Condition

When a converter is in current limit mode the output voltages will drop as

the output current demand increases. If the output voltage drops too low, the

magnetically coupled voltage used to develop primary side voltages will also

drop, thereby shutting down the PWM controller. Following a time-out period

Figure 4. Driving the Remote On/Off Control Pin

Thermal Shutdown

USQ converters are equipped with thermal-shutdown circuitry. If the internal

temperature of the DC/DC converter rises above the designed operating tem

-

perature (See Performance Specifications), a precision temperature sensor

will power down the unit. When the internal temperature decreases below

the threshold of the temperature sensor, the unit will self start.

Output Overvoltage Protection

The output voltage is monitored for an overvoltage condition via magnetic

coupling to the primary side. If the output voltage rises to a fault condition,

which could be damaging to the load circuitry (see Performance Specifica

-

tions), the sensing circuitry will power down the PWM controller causing

the output voltage to decrease. Following a time-out period the PWM will

restart, causing the output voltage to ramp to its appropriate value. If the

fault condition persists, and the output voltages again climb to excessive

levels, the overvoltage circuitry will initiate another shutdown cycle. This

on/off cycling is referred to as "hiccup" mode.

Input Reverse-Polarity Protection

If the input-voltage polarity is accidentally reversed, an internal diode will

become forward biased and likely draw excessive current from the power

source. If the source is not current limited (<5A) nor the circuit appropriately

fused, it could cause permanent damage to the converter.

Input Fusing

Certain applications and/or safety agencies may require the installation of

fuses at the inputs of power conversion components. Fuses should also be

used if the possibility of a sustained, non-current-limited, input-voltage polar

-

ity reversal exists. For DATEL USQ Series DC/DC Converters, slow-blow

fuses are recommended with values no greater than the following:

V

OUT Range Fuse Value -D48 Fuse Value -D24

1.2VOUT Models 1.5 Amps —

1.5V

OUT Models 2.5 Amps —

1.8V

OUT Models 3 Amps —

2.5V

OUT Models 3.5 Amps —

3.3V

OUT Models 4 Amps —

5

to 24VOUT Models 6 Amps 10 Amps

See Performance Specifications for Input Current and Inrush Transient limits.

2

1

3

200k

+5V

REF

200k

+INPUT

EQUIVALENT CIRCUIT FOR

POSITIVE AND NEGA

TIVE

LOGIC MODELS

CONTR

OL

–INPUT

ON/OFF

CONTRO

L

Start-Up Time

The V

IN to VOUT Start-Up Time is the interval between the point at which

a ramping input voltage crosses the Start-Up Threshold voltage and the

point at which the fully loaded output voltage enters and remains within it

specified

±1% accuracy band. Actual measured times will vary with input

source impedance, external input capacitance, and the slew rate and final

value of the input voltage as it appears to the converter.The On/Off to V

OUT

Start-Up Time assumes the converter is turned off via the Remote On/Off

Control with the nominal input voltage already applied. The specification

defines the interval between the point at which the converter is turned on

(released) and the point at which the fully loaded output voltage enters and

remains within its specified

±1% accuracy band.

Trimming Output Voltage

USQ converters have a trim capability (pin 6) that enables users to adjust

the output voltage from +10% to –20% (refer to the trim equations and trim

graphs that follow). Adjustments to the output voltage can be accomplished

with a single fixed resistor as shown in Figures 5 and 6. A single fixed resis

-

tor can increase or decrease the output voltage depending on its connection.

Resistors should be located close to the converter and have TCR's less than

100ppm/°C to minimize sensitivity to changes in temperature. If the trim

function is not used, leave the trim pin open.

of 5 to 15 milliseconds, the PWM will restart, causing the output voltages to begin

ramping to their appropriate values. If the short-circuit condition persists,

another shutdown cycle will be initiated. This on/off cycling is referred to

as “hiccup” mode. The hiccup cycling reduces the average output current,

thereby preventing internal temperatures from rising to excessive levels. The

USQ is capable of enduring an indefinite short circuit output condition.

2 0 A , S I N G L E O U T P U T D C / D C C O N V E R T E R S