11

The motor shipped with your saw is a 1-1/2 H.P. at 115 volts or 2 H.P. at 230 volts, Ball Bearing,

Capacitor Start/Capacitor Run motor. This motor has been especially selected to best supply power

to your machine, and the relative safety of the machine is enhanced by its use. Use only this motor, as

the use of other motors may be detrimental to the performance and safety of the saw.

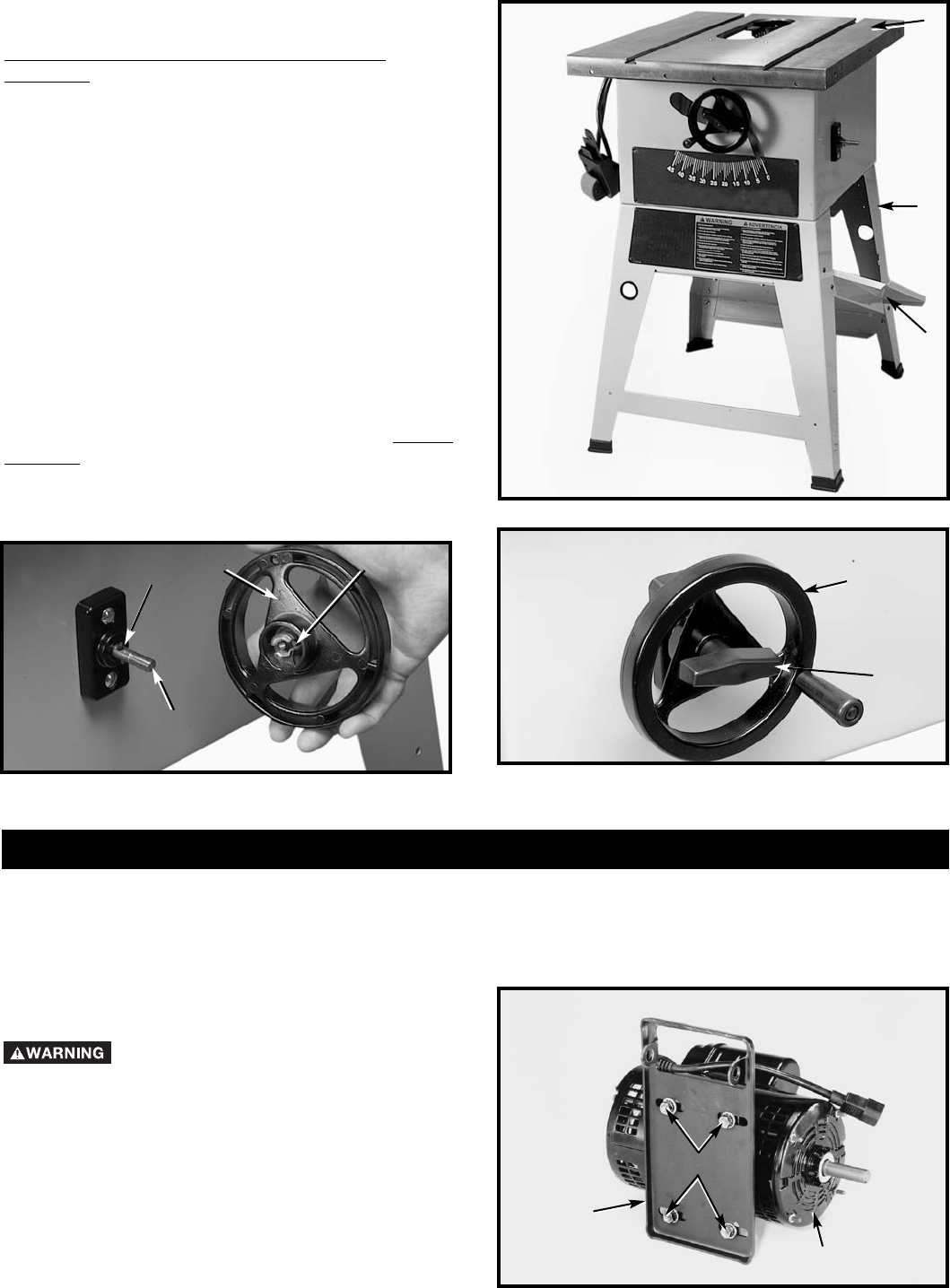

Fig. 11

ASSEMBLING MOTOR TO

MOTOR MOUNTING PLATE

DISCONNECT MACHINE FROM THE

POWER SOURCE.

1. Assemble the motor (A) to the motor mounting plate

(B) as shown in Fig. 11, using four 5/16-18 carriage

bolts, flat washers, star washers, and hex nuts (C). Insert

bolts through the holes in motor base and mounting

plate, then assemble flat washers, then star washers,

and hex nuts.

NOTE: Do not completely tighten the hex nuts at this

time.

A

C

B

Fig. 9

Fig. 10

4. Push down on the top of the saw (E) Fig. 8 until the

stand legs (F) are positioned firmly on the floor surface.

Secur

ely tighten all saw and stand mounting

hardware. Note that panel (G) is not only a support for

a stand, but also serves as a dust chute.

5. Fig. 8, illustrates the saw assembled to the stand.

NOTE: If it becomes necessary to move the saw to

another location, additional adjustments may be

required.

ASSEMBLING BLADE

TILTING HANDWHEEL

1. Attach blade tilting handwheel (A) Fig. 9 to shaft (B).

Make certain slot (C) in handwheel is engaged with roll

pin (D) on the shaft.

2. Thread locking lever (E) Fig. 10, on shaft and tighten

securely.

3. Fig. 10 illustrates the blade tilting handwheel (A) and

locking lever (E) assembled to the saw.

D

B

A

C

A

E

MOTOR ASSEMBLY

Fig. 8

E

F

G