19

Fig. 45

A

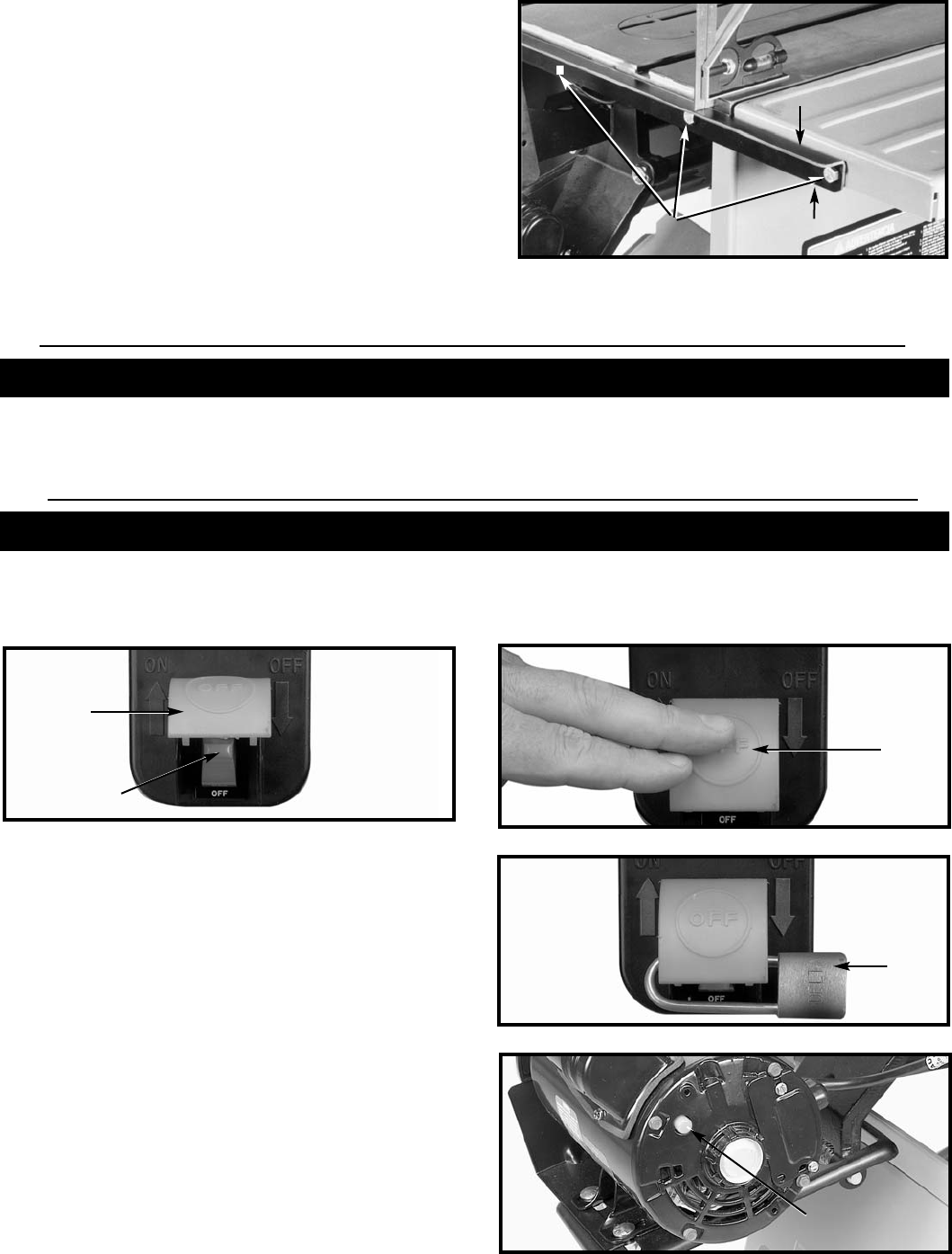

STARTING AND STOPPING SAW

1. The on/off switch is located underneath the switch shield (A) Fig. 42. To turn the saw “ON”, move

switch trigger (B) to the up position.

2. To turn the saw “OFF”, push down on switch shield (A) Fig. 43.

Fig. 42

Fig. 43

A

B

A

Fig. 44

LOCKING SWITCH IN

THE “OFF” POSITION

IMPORTANT: When the machine is not in use, the

switch should be locked in the “OFF” position to

prevent unauthorized use,

using a padlock (C) Fig. 44

with a 3/16" diameter shackle.

In the event of a power outage, always lock switch in

“OFF” position until the main power is restored.

OVERLOAD PROTECTION

Some saws are equipped with motors that do not have

a resettable overload. However, if your motor is

equipped with a resettable overload and the motor shuts

off or fails to start due to overloading, move the switch

to the “OFF” position and let the motor cool three to five

minutes. After cooling for three to five minutes, push the

reset button (A), Fig. 45. The saw can then be turned on

again in the usual manner. Note: Overloading occurs due

to cutting stock too fast, using a dull blade, using the

saw beyond its capacity, low voltage, and etc.

C

OPERATING CONTROLS

FASTENING STAND TO SUPPORTING SURFACE

IMPORTANT: IF, DURING OPERATION, ANY TENDENCY EXISTS FOR THE SAW TO TIP OVER, SLIDE OR WALK

ON THE SUPPORTING SURFACE, THE SAW STAND SHOULD BE SECURED TO THE FLOOR SURFACE. THE

RUBBER FEET OF THE STAND FEATURE HOLES WHICH ALLOW EASY MOUNTING WITHOUT REMOVING THE

SAW FROM THE STAND.

Fig. 41

A

B

D

BACK SUPPORT RAIL MODEL 36-441B

NOTE: IF YOUR MODEL DOES NOT USE A LEFT SIDE

SHEET METAL WING, THE BACK RAIL SUPPORT IS

NOT USED.

Fasten the rear table support (A) Fig. 41, to the saw table.

Insert a 3/8-16x1" hex head screw (B), through holes in rear

support and table, place a 3/8 washer onto the screw and

thread a 3/8-16 hex nut onto screw and tighten securely.

Repeat this process for the remaining holes. When

completely assembled, the flat edge (D) Fig. 41 of the rear

table support will face upward.

NOTE: One extra screw, washer and nut will be left for

mounting the switch to the front of the sheet metal

extension wing with a unifence.