1. Position molding with top of the molding resting on the

base of the saw

2. Miter left 45°

3. Save left side of cut

OUTSIDE CORNER:

Left side

1. Position molding with bottom of molding against the base

of the saw

2. Miter right 45°

3. Save left side of cut

NOTE: If the cut must be made somewhere other than 1"

(25.4mm) from the end of the molding: cut off the molding at

90° approx. 1" (25.4mm) longer than your final length then

make the miter cut as described above.

Right side

1. Position molding with bottom of the molding against the

base of the saw

2. Miter left 45°

3. Save the right side of cut

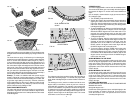

A third method of making the cut necessary (Figure 29) is to

make a zero degree miter, 45 degree bevel cut. Your saw can

cut a bevel 12" (305mm) wide.

CUTTING BASE MOLDING LAYING FLAT AND USING

THE BEVEL FEATURE

• All cuts made with the saw set at 45° bevel and

0 miter.

• All cuts made with back of molding laying flat on the saw

and the bottom of the molding against the fence, as shown

in Figure 29.

INSIDE CORNER:

Left side

1. Bevel 45° right

2. Save right side of cut

Right side

1. Bevel 45° left

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Bevel 45° left

2. Save right side of cut

Right side

1. Bevel 45° right

2. Save left side of cut

CUTTING CROWN MOLDING

To fit properly, crown molding must be cut with extreme

accuracy.

The two flat surfaces on a given piece of crown molding are

at angles that, when added together, equal exactly 90

degrees. Most, but not all, crown molding has a top rear angle

13

English

(the section that fits flat against the ceiling) of 52 degrees

and a bottom rear angle (the part that fits flat against the

wall) of 38 degrees.

Your sliding compound miter saw has special pre-set miter

latch points at 31.6 degrees left and right for cutting crown

molding flat at the proper angle. There is also a mark on the

bevel scale at 33.9 degrees.

The chart on the next page gives the proper settings for

cutting crown molding. (The numbers for the miter and bevel

settings are very precise and are not easy to accurately set on

your saw.) Since most rooms do not have angles of precisely

90 degrees, you will have to fine tune your settings anyway.

PRETESTING WITH SCRAP MATERIAL IS

EXTREMELY IMPORTANT!

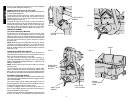

METHOD FOR CUTTING CROWN MOLDING ANGLED

BETWEEN THE FENCE AND TABLE (NESTED)

Place the molding on the table at an angle between the

fence and the saw table, as shown in Figure 31. Use of the

crown molding fence accessory (DW7084) is highly

recommended because of its degree of accuracy and con-

venience. The crown molding fence accessory is available for

purchase from your local dealer.

The advantage to cutting crown molding using this method is

that no bevel cut is required. Minute changes in the miter

angle can be made without affecting the bevel angle. This

way, when corners other than 90 degrees are encountered,

the saw can be quickly and easily adjusted for them. Use the

crown molding fence accessory to maintain the angle at

which the molding will be on the wall.

INSTRUCTIONS FOR CUTTING CROWN MOLDING

ANGLED BETWEEN THE FENCE AND BASE OF THE

SAW FOR ALL CUTS:

1. Angle the molding so the bottom of the molding (part which

goes against the wall when installed) is against the fence

and the top of the molding is resting on the base of the

saw, as shown in Figure 31.

2. The angled “flats” on the back of the molding must rest

squarely on the fence and base of the saw.

INSIDE CORNER:

Left side

1. Miter right at 45°

2. Save the right side of cut

Right side

1. Miter left at 45°

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Miter left at 45°

2. Save right side of cut

Right side

1. Miter right at 45°

2. Save left side of cut

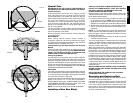

FIG. 30

FENCE

TABLE

CROWN MOLDING FLAT ON TABLE AND AGAINST FENCE

CROWN MOLDING BETWEEN FENCE AND TABLE

FIG. 31

BACK OF

MOLDING

TABLE

TOP OF

MOLDING

FENCE

BLADE

FIG. 32

RIGHT

BOTTOM OF

MOLDING