11

ENGLISH

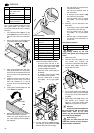

Saw blade alignment

1. If necessary, crank the saw blade

fully up using the handwheel to

check the alignment.

− The saw blade must be aligned

exactly parallel with the side

edges of the table top.

− It must not touch the table insert

extrusion (neither in the 90° posi-

tion nor in the 45° bevel position).

To correct the alignment:

2. Loosen the six flange nuts holding

the fastening brackets under the

saw table by approx. one turn.

3. Move the fastening brackets, with

the motor unit/chipcase assembly

attached to it, as required, until the

alignment is correct.

4. Tighten the six flange nuts of the

two fastening brackets.

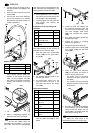

Riving knife installation

A

Danger!

The riving knife is one of the

safety devices and has to be correctly

installed for a safe operation:

1. Loosen the hexagon nut (= Keps

nut) (116) at the pressure plate

(117) approx. two turns.

2. Slide the riving knife (118) as illus-

trated between riving knife carrier

(119) and pressure plate(117).

3. Adjust riving knife (see below) and

tighten the Keps nut.

Riving knife adjustment.

In order to match the riving knife exactly

with the saw blade, its position can be

adjusted in two planes:

− in the distance to the saw blade;

− in its lateral alignment.

Distance to the saw blade:

The distance between the saw blade's

peripheral edge and the riving knife shall

be between 3...8 mm.

The riving knife must project at least the

same distance over the saw table as the

saw blade.

1. If necessary, loosen the Keps nut

(120) on the riving knife one turn.

2. Adjust distance of the riving knife to

the saw blade.

3. Tighten the Keps nut.

Lateral alignment:

riving knife and saw blade must be per-

fectly in line.

• Turning the four hexagon socket

head cap screws (121) on the motor

carrier unit below the saw table

clockwise

= riving knife is moved to the right.

• Turning the four hexagon socket

head cap screws (121) on the motor

carrier unit below the saw table

counter-clockwise

= riving knife is moved to the left.

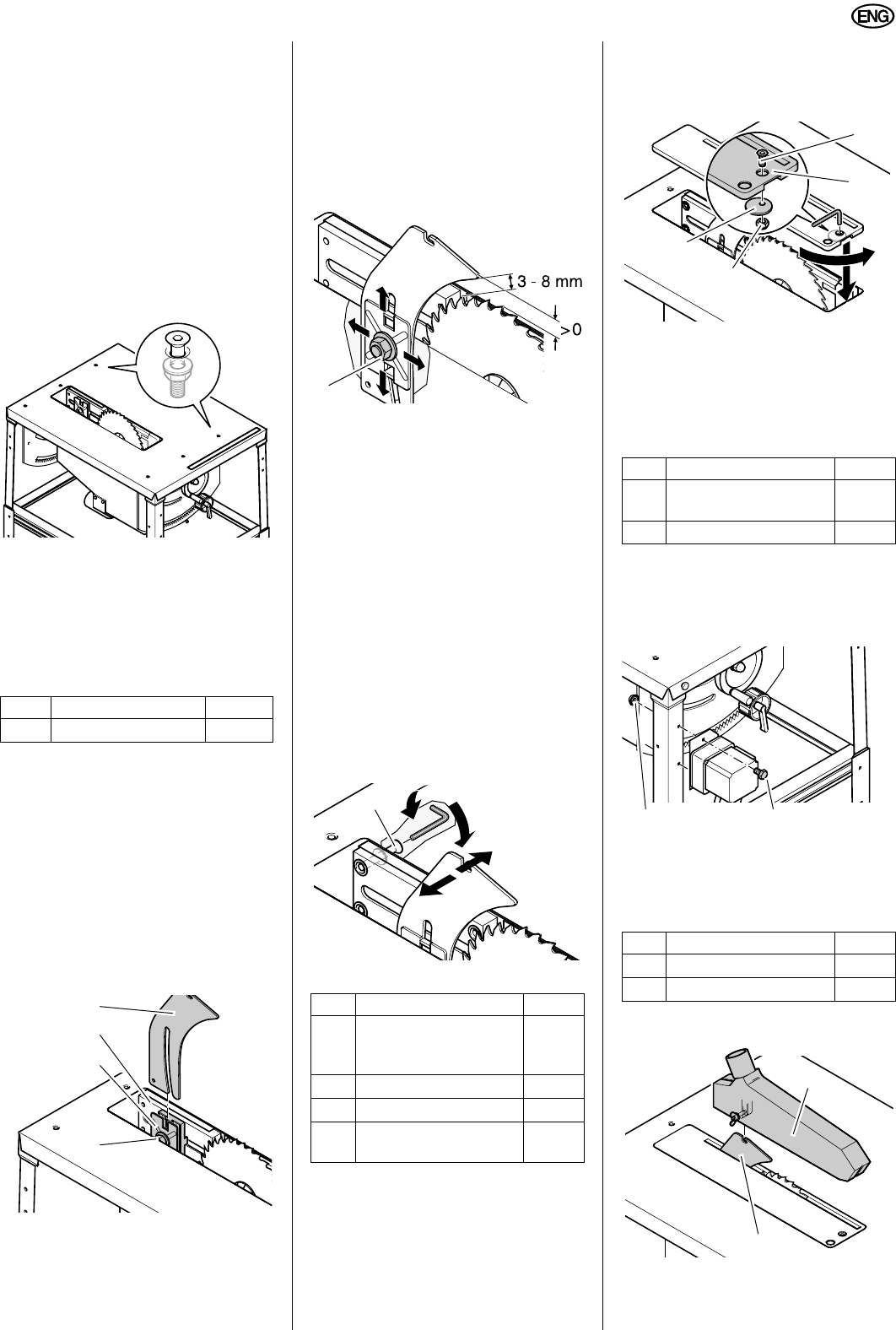

Table insert extrusion installation

1. Put the countersunk screw (122)

from the top through the hole in the

table insert extrusion (123).

2. From the underside, put the cam

plate (124) on the flat head screw

and secure with the prevailing

torque-type hexagon nut (125) – the

cam plate remains rotatable.

3. Turn flat head screw clockwise

(viewed from top) until it stops, and

place table insert extrusion flush into

the table top's slot.

4. Turn the countersunk screw coun-

ter-clockwise: the cam plate will

engage in the recess of the saw

table and locks the table insert

extrusion in place.

Mounting the switch

• Attach the switch plate with two

each hexagon head screws (126)

and flange nuts (127) to the left front

leg. The switch buttons must point to

the right-hand side.

A

Caution!

Make sure the cable does not

run over sharp edges and is not bent.

Installing the dust collection gear

1. Install blade guard (128) on the riv-

ing knife (129).

2. Push one end of the suction hose

(131) on the blade guard's suction

port (130).

Item Description Qty.

118

Riving knife

1

117

116

119

118

Item Description Qty.

122

Hex. socket counter-

sunk head screw

M6 x 16

1

123

Table insert

1

124

Cam plate 25 mm

1

125

Hexagon nut, prevailing

torque type, M6

1

120

121

Item Description Qty.

126

Hexagon head screw

M8 x 16

2

127

Flange nut M8

2

Item Description Qty.

128

Blade guard

1

131

Suction hose

1

122

123

124

125

126127

128

129