9

ENGLISH

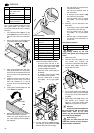

4. Slide pinion shaft (78) from the front

into the setting tube, so that it will

rest on the gears of the front and

rear chipcase guide panels (the

threaded end of the pinion shaft

must be at the front of the saw).

5. Put setting knob (80) on the pinion

shaft and secure in place with

washer (81) and hexagon thin nut

(82).

6. Turn the prevailing torque-type hex-

agon nut (76) on the threaded rod

(79), so that approx. 2 thread will

protrude.

7. Slide the threaded rod into the pin-

ion shaft from the rear of the saw.

8. At the front, put a washer (83) and a

lock lever (84) on the threaded rod

and tighten.

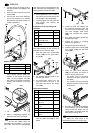

Handwheel installation

1. Put the turning tang (81) on the cap

screw (82), then screw on a hexa-

gon nut (79) so far down that the

turning tang will still easily turn.

2. Fasten the thus prepared turning

tang with the second hexagon nut

(79) to the handwheel (80) and

tighten both hexagon nuts.

3. Put handwheel on the threaded

spindle of the motor carrier unit and

secure with washer (84) and cap nut

(83) – to counter, hold the hexagon

nut on the spindle.

Motor installation

• Fasten motor (86) with hexagon

head screws (85) to the motor car-

rier unit.

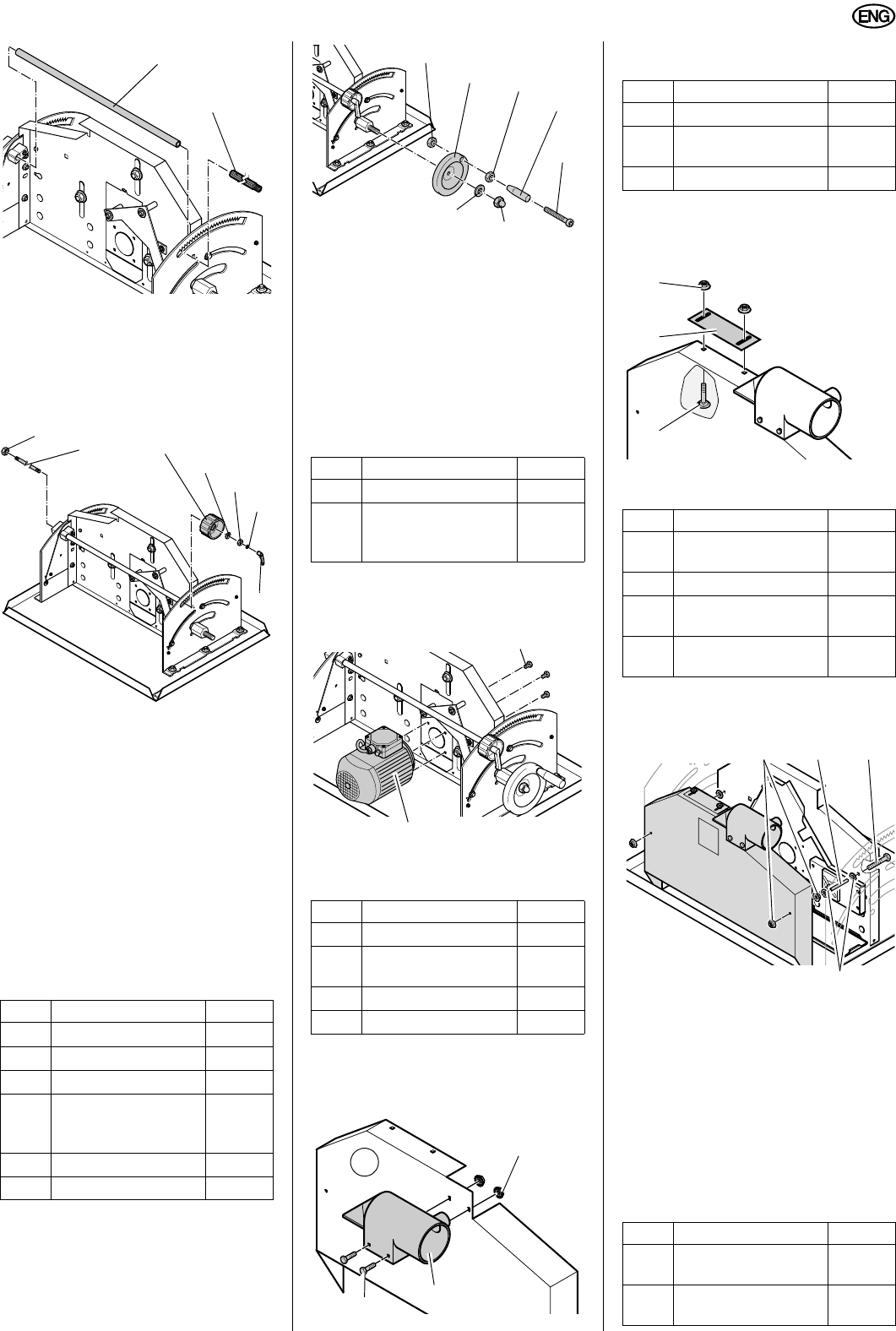

Installation of dust extraction port to

the chipcase

− Attach the suction port (87) with two

hexagon head screws (88) and

flange nuts (89) as illustrated to the

outside of the chipcase (90).

Installation of sliding plate port to the

chipcase

• Install the sliding plate (91) on the

outside of the chipcase, using two

each saucer-head screws (92) and

flange nuts (93).

Installation of chipcase to the motor

carrier unit

1. Insert one each hexagon head

screw (94) from the motor side into

the motor carrier unit.

2. From the saw blade side, put one

each washer (95), distance sleeve

(96) and another washer (95) on the

hexagon head screw, then secure

with one each prevailing torque type

hexagon nut (97).

3. Slide the pre-assembled chipcase

onto the two hexagon head screws

and fasten with one each prevailing

torque type hexagon nut (97).

Cover installation

Item Description Qty.

79

Hexagon nut M6

2

80

Handwheel

1

81

Turning tang

1

82

Hex. socket counter-

sunk head screw

M6 x 60

1

83

Cap nut M14

1

84

Washer 15/28

1

77

78

76

81

82

83

80

79

84

Item Description Qty.

86

Motor

1

85

Hexagon head

screw, prevailing

torque type, M6 x 16

4

Item Description Qty.

87

Dust extraction port

1

88

Hexagon head screw

M5 x 16

2

89

Flange nut M5

2

90

Chipcase

1

79

80

79

81

82

83

84

85

86

87

88

90

89

Item Description Qty.

91

Sliding plate

1

92

Cup square neck

screw M5 x 16

2

93

Flange nut M5

2

Item Description Qty.

94

Hexagon head screw

M6 x 80

2

95

Washer 6.4/12.5

4

96

Distance sleeve 6 x

60

2

97

Hexagon nut, prevail-

ing torque type, M6

4

Item Description Qty.

98

Hexagon nut, prevail-

ing torque type, M6

2

99 Distance sleeve

6.4 x 1515

2

93

91

92

97 94

95

96