12

ENGLISH

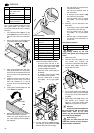

3. Fit other end of the suction hose to

the dust extraction port (133) on the

chipcase.

4. Hook the suction hose into the hose

carrier (132).

5. Connect the saw's dust extraction

port at the chipcase to a suitable

dust collector (see "Dust collector" in

chapter "Operation").

Scale installation

1. Fasten scale (135) with three pan-

head tapping screws (134) and

washers to the recess of the saw

table – do not yet tighten: the scale

still needs to be adjusted according

position and thickness of the saw

blade.

2. Place a straightedge against the

right-hand side of the saw blade.

3

Note:

As the saw blade's teeth are

alternately bent outwards (= set of the

saw teeth), make sure the straightedge

does not touch any of the teeth set to the

right. Otherwise the straightedge is not

exactly parallel with the saw blade.

3. Scale adjustment: the "0" mark of

the scale must coincide exactly with

the left edge of the straightedge.

4. Carefully tighten the pan head tap-

ping screws, then remove the

straightedge.

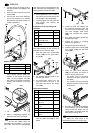

Installation on the rip fence guide

extrusion

The guide extrusion for the rip fence is

fitted to the front of the saw table.

1. Slide the head of the saucer-head

screws (138) into the guide extru-

sion (139).

2. Put distance sleeves (137) on the

saucer-head screws.

3. Fit saucer-head screws into the

holes provided at the front of the

saw table and secure with flange

nuts (136).

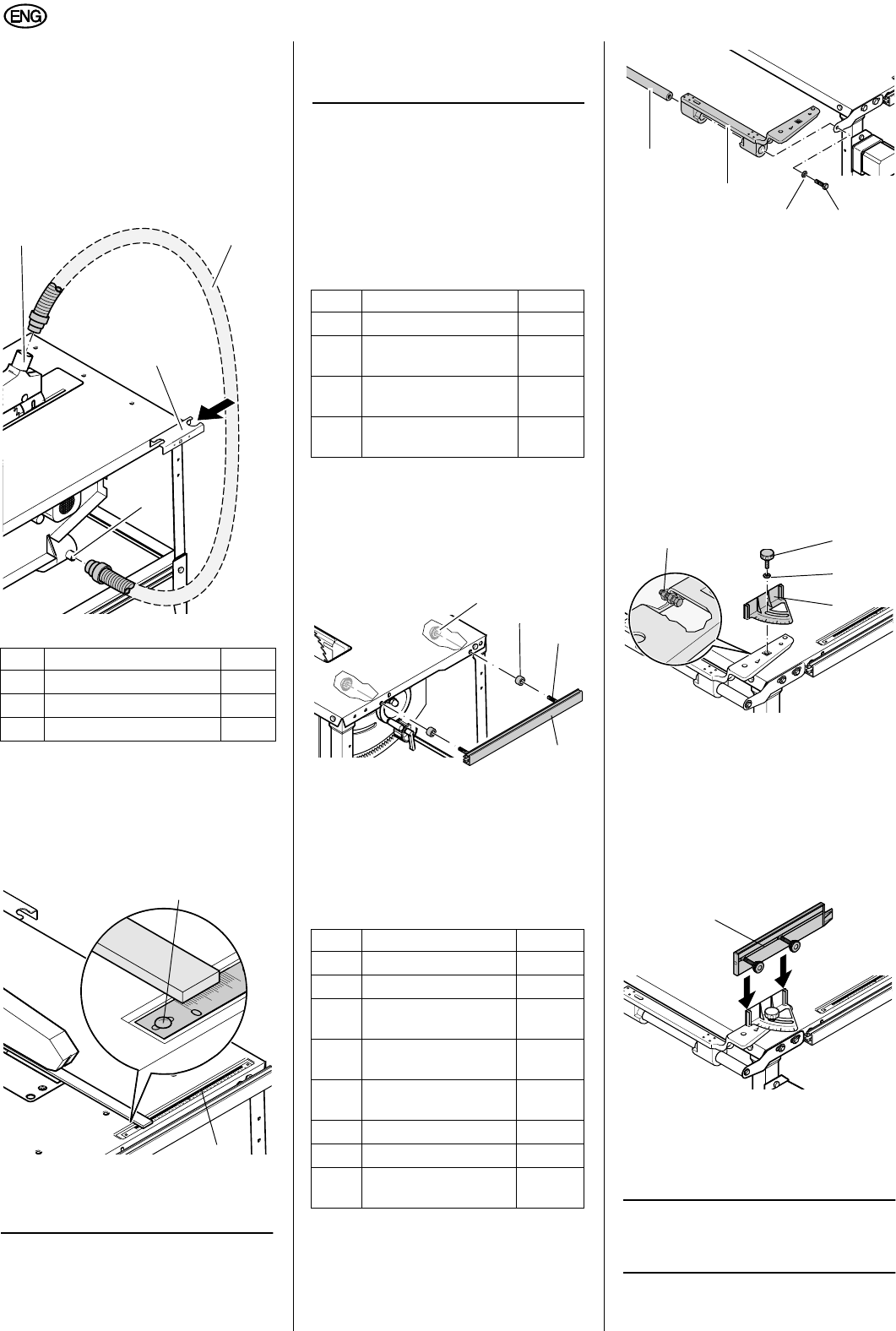

Mitre fence assembly

1. Slide the lower fence carrier (141)

onto the guide bar (140) as illus-

trated.

2. Install the guide bar between the

two guide bar brackets at the left

front and rear of the saw table, using

one each hexagen head screw

(143) and serrated lock washer

(142).

3. Align guide bar exactly parallel with

the table top's edge.

4. Tighten all screws of mounting

brackets and guide bar.

5. Swing the lower fence carrier up.

6. Install the upper fence carrier (147)

with washer (146) and star-knob

screw (145).

7. Place the short fence extrusion

(148) on the carrier and secure in

position with the knurled nuts:

− the plastic nose of the fence

extrusion must point towards the

saw blade

− the washers must be positioned

between the fence carrier and the

knurled nuts

8. By means of the set screw (144) the

fence extrusion can be set exactly

sqare to the saw blade. The set

screw (144) is accessible when the

mitre fence is swung down.

3

Note:

When the mitre fence is not

required swing it down, out of the way.

Item Description Qty.

134

Pan-head tapping screw

3

135

Scale

1

–

Washer 4.3/9

3

130 131

133

132

134

135

Item Description Qty.

136

Flange nut M8

2

137

Distance sleeve 8 x

16

2

138

Cup square neck

screw M8 x 30

2

139

Guide extrusion, rip

fence

1

Item Description Qty.

140

Guide bar

1

141

Fence carrier, lower

1

142

Serrated lock washer

8.4

2

143

Hexagon head screw

M8 x 16

4

145

Star-knob screw M8

x 23

1

146

Washer 8.4/17

1

147

Fence carrier, upper

1

148

Fence extrusion,

short

1

136

137

138

139

140

141

142 143

145

146

147

144

148