7

ENGLISH

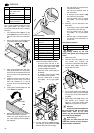

In order to prevent the set blade tilt to

change during cutting, its position is

locked with the lock lever (50).

Handwheel for setting the depth of

cut

The depth of cut can be adjusted by

turning the handwheel (51).

Fence

The saw is equipped with two fences:

• Mitre fence (for cross/mitre cuts):

For use as mitre fence the short

fence extrusion (52) must be

installed. The mitre fence is

mounted on a guide bar, fastened to

the left-hand side of the saw table.

The plastic nose of the fence extru-

sion must point towards the saw

blade.

For mitre cuts, the fence extrusion is

adjustable to 45° maximum.

• Rip fence (for ripping):

For use as rip fence the long fence

extrusion (53) must be installed. It is

mounted on the guide extrusion at

the front of the saw table.

After loosening the two knurled nuts

(54), the fence extrusion can be

removed and shifted:

Wide edge:

− for cutting thick stock

Small edge:

− for cutting thin stock;

− when the saw blade is tilted.

A

Danger!

Modifications of the saw or the

use of parts not tested and approved

by the equipment manufacturer can

lead to unforeseen damage during

operation!

− Assemble the saw in strict

accordance with these instruc-

tions.

− Use only the parts supplied as

standard delivery.

− Do not change any parts.

Only if you follow the instructions exactly

does the saw conform to the safety regu-

lations and can be safely operated.

If you also observe the following notes,

the assembly will cause no problems:

• Read the instructions for each step

before executing it.

• Lay out the parts required for each

assembly step.

Required tools

− Hex. wrench 4 mm

− Hex. wrench 5 mm

− Hex. wrench 6 mm

− Wrench 10 mm

− Wrench 13 mm

− Wrench 17 mm

− Wrench 19 mm

− Ring spanner 46 mm

− Philips screwdriver

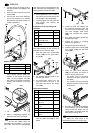

Chipcase guide panel installation

The chipcase guide panels (55) and (57)

are installed on the underside of the

table top (58).

1. Place table top with the folds facing

up on a sturdy support.

2. Attach front chipcase guide panel

(57) and rear chipcase guide panel

(55) using three each countersunk

screws (59) and flange nuts (56) to

the underside of the table top(58):

− The front of the saw is where the

recess for the rip fence scale is

located in the table top (see

image detail).

− The square ends of the curved

oblong holes (arrows) must face

the edge of the table top which is

closer to the opening for the saw

blade.

− The folded edges of the chipcase

guide panels must point out-

wards.

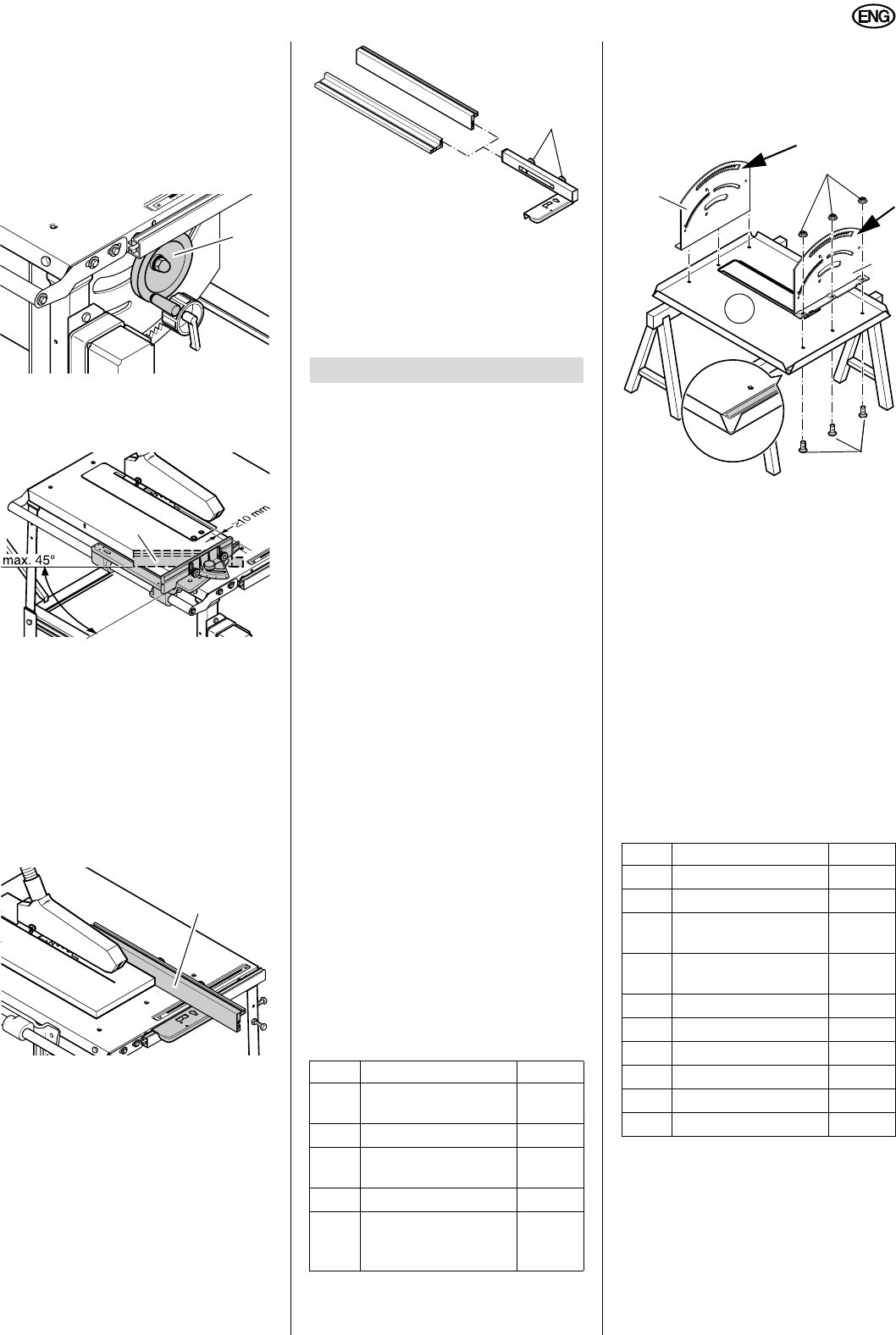

Bearing plate installation

1. Attach two each cam plate (61)

(hole not in centre) with hexagon

head screw (62) and hexagon nut

(60) fingertight to the inside of each

chipcase guide panel.

51

52

53

7. Assembly

Item Description Qty.

55

Chipcase guide

panel, rear

1

56

Flange nut M8

6

57

Chipcase guide

panel, front

1

58

Table top

1

59

Hex. socket counter-

sunk head screw

M8 x 25

6

54

Item Description Qty.

60

Hexagon nut M6

4

61

Cam plate

4

62

Hexagon head screw

M6 x 16

4

63

Hexagon head screw

M8 x 20

4

64

Guide roller

4

66

Bearing plate, rear

1

67

Flange nut M8

4

68

Bearing plate, front

1

70

Indicator

1

71

Angle scale

1

56

57

55

58

59