14

ENGLISH

− hoses must fit the outer diameter

of the dust extraction ports (blade

guard 36 mm; chipcase 100 mm);

− air flow volume ≥ 460 m

3

/h;

− vacuum at dust extraction port of

saw

≥ 530 Pa;

− air speed at dust extraction port

of saw

≥ 20 m/ s.

The dust extraction ports are located at

the chipcase assembly and at the saw

blade guard.

Observe the dust collector's operating

instructions as well!

Operation without a dust collector is only

possible:

− outdoors;

− for short-term operation

(up to a maximum of 30 minutes);

− with dust respirator.

A

Caution!

If no dust collector is hooked

up the sliding plate on the chipcase

must be opened, otherwise chips and

saw dust will build up inside the chip-

case.

To open the sliding plate:

1. Loosen both nuts (150) on the

underside of the chipcase slightly.

2. Slide sliding plate (151) to the side.

3. Tighten nuts (150).

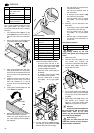

8.2 Setting the depth of cut

A

Danger!

Parts of the body or objects in

the setting range can be caught by

the running saw blade! Set the depth

of cut only with the saw blade at

standstill!

The saw blade's cutting height needs to

be adapted the the height of the work-

piece: the blade guard shall rest with its

front edge on the workpiece.

• Set the depth of cut by turning the

handwheel (152) on the chipcase.

3

Note:

To compensate for possible play

in the blade height setting mechanism,

always raise the blade to the desired

position.

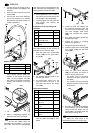

8.3 Setting the saw blade tilt

A

Danger!

Parts of the body or objects in

the setting range can be caught by

the running saw blade! Set the depth

of cut only with the saw blade at

standstill!!

The saw blade tilt is steplessly adjusta-

ble between 0° and 45°.

1. Loosen the lock lever (154).

2. Using the handwheel (153), set the

desired blade tilt.

3. Tighten the lock lever to secure the

saw blade in the set position.

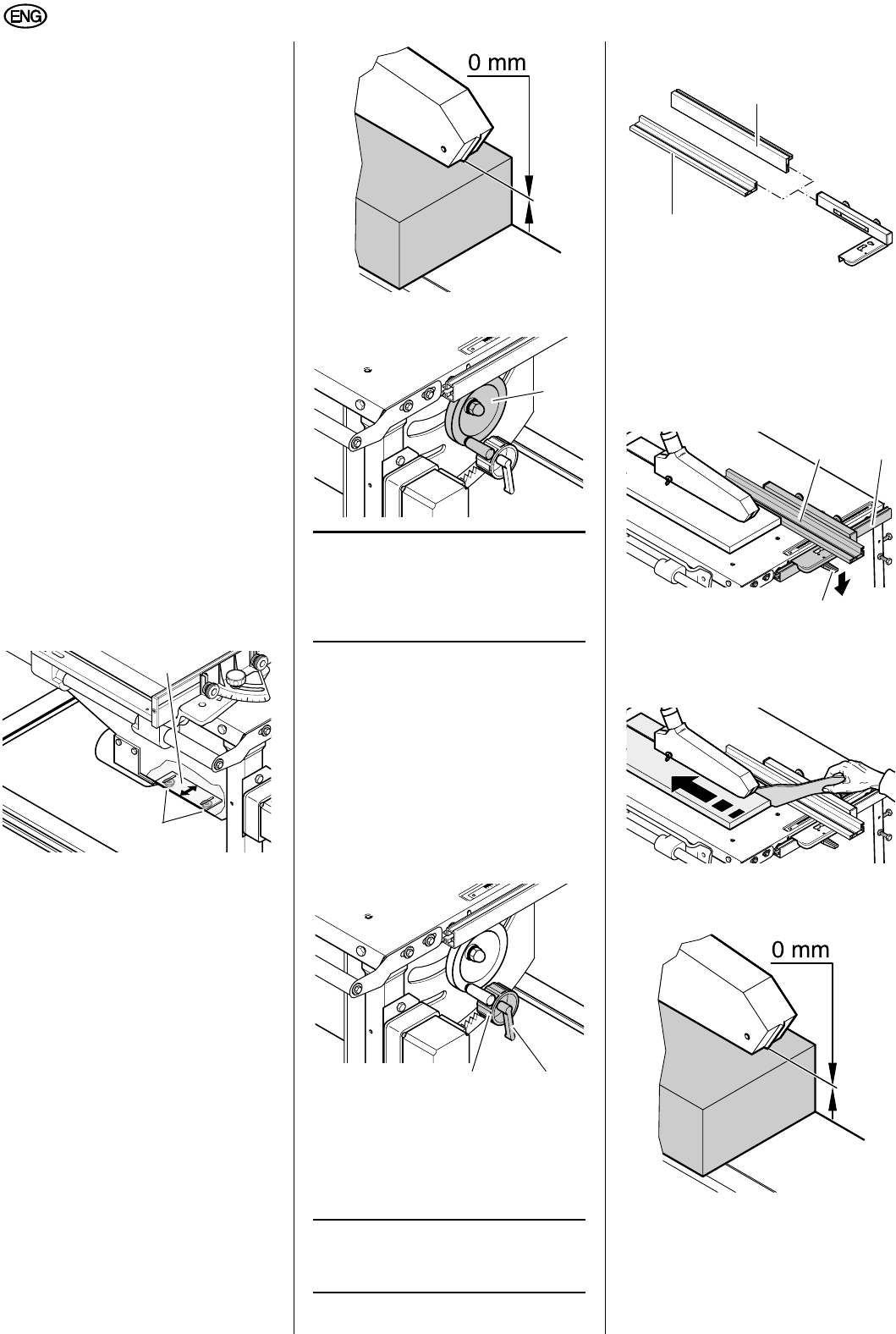

8.4 Sawing with the rip fence

3

Note:

When sawing with the rip fence

the long fence extrusion must be used.

1. Adopting the fence extrusion to the

workpiece height:

− Wide edge (155) =

for cutting thick stock

− Small edge (156) =

for cutting thin stock

2. The rip fence (157) is placed from

top onto the guide extrusion (158) at

the front of the saw and locked with

the lock lever (159).

A

Danger!

Always use the push stick if

the distance between saw blade and

rip fence is less than 120 mm.

3. Set the cutting height of the saw

blade. The blade guard must rest

with its front edge on the workpiece.

4. Set saw blade tilt and lock.

5. Start motor.

6. Cut workpiece in a single pass.

7. Switch machine off if no further cut-

ting is to be done immediately after-

wards.

151

150

152

153 154

155

156

157 158

159