Controller Setup for Modbus MRLDS MRLDS Modbus Version (809-101x) • 13

field to change the name, and press the down

or right arrow to move to the (sensor) Type

field. Use the “.” and “—” keys to scroll

through the options and select IRLDS. (The

Gain and Offset parameters are automatically

configured for you.)

13. Use the arrow keys to move off the active

fields and press 0 (zero) twice to go back to

the main screen.

4.4.5 BEC and RMCC Controllers

Less Than Version 2.1

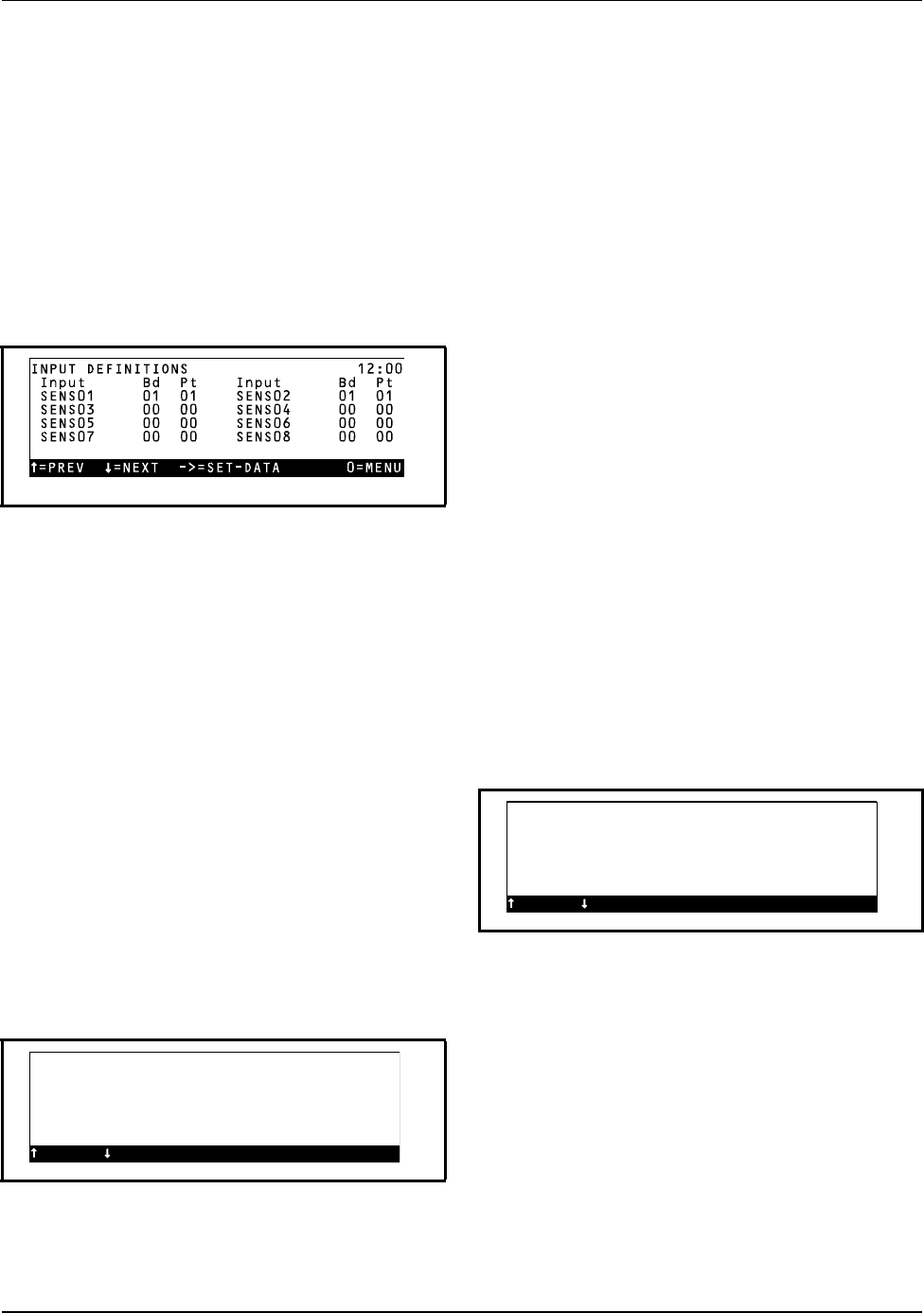

4.4.5.1 Input Definitions

Locate the screens in the BEC or RMCC that are used

to define input board and points. This is usually achieved

by pressing 7 then 1 from the Main Menu. Press the

DOWN ARROW key several times until the SENS01-

SENS08 inputs are shown.

The 16AI connected to the IRLDS’s output terminals

must be set up in the REFLECS’s system software. If the

16AI was given a unique board number by setting the dip

switch S3, and wired to the terminals so that each zone

number corresponds to a 16AI point number (zone 01 con-

nected to point 01, for example), these board and point ad-

dresses must now be entered into the REFLECS.

The screen above shows how the board and point ad-

dresses for zone 1 would be set up for a 16AI board num-

bered 1. Both SENS01 and SENS02 are set up as 01:01 so

that SENS01 can monitor concentration and SENS02 can

monitor fault status.

Set up the remaining sensors using the instructions giv-

en above. For each point on the 16AI, set up two sensors

with the same addresses.

4.4.5.2 Sensor Setup

Locate the screen in the BEC or RMCC where sensors

are set up. This is usually a menu option in the Sensors

Menu, which may be reached from the Main Menu.

The 0-4.8V signal is a linear signal representing a mea-

sured concentration of 0-1200 ppm, and a voltage of 5.0V

indicates a fault. In order for the REFLECS to read these

voltages correctly, the REFLECS sensor inputs must be

configured as linear sensors.

Name

A name for the sensor input may be entered in the Name

field. Since each IRLDS zone is set up with two REFLECS

sensor inputs, choose names for each input that distinguish

the input’s function. For example, the sensor input set up to

read leak concentrations on zone 1 should have a name like

REFR LK ZN 01, and the input set up to monitor fault sta-

tus should have a name like FAULT ZN 01.

Type

All sensor inputs connected to an IRLDS should be set

up as linear sensors. Enter (L)inear in the Type field.

Logging Interval

The logging interval is the amount of time between log

entries in the REFLECS’s Data Log.

When choosing a logging interval, keep in mind the

amount of time it takes an IRLDS to go through an entire

cycle of samplings. For example, a 16-valve IRLDS with

30 second sampling times for each zone takes a total of

eight minutes to sample all zones. Choosing a logging in-

terval smaller than the IRLDS’s cycle time will simply

clutter the REFLECS data log with multiple copies of the

same sample.

4.4.5.3 Sensor Setpoints

Locate the screen in the BEC or RMCC where sensor

set points are specified. This is usually a menu option in the

Sensors Menu, which may be reached from the Main

Menu.

After the linear sensors have been set up, the REFLECS

must be told how to interpret the linear voltage given by the

IRLDS.

Eng. Unit

The REFLECS does not require any specific engineer-

ing unit to be specified for sensor values. However, for eas-

ier reading of status screens and data logs, “PPM” should

be entered for sensor inputs that read concentration, and

SENSOR SETUP 12:00

#:01 Status:OFF Name:REFR LK ZN 01

Type: Linear

(T)mp (1)00 (5)00 (R)fLeak (K)Watt

(H)um (2)00 (D)ig (L)inear L(Q)Lev

(6)450 Tmp Dew(P)nt

Logging Interval (HH:MM:SS): 00:03:00

=PREV =NEXT ->=SET-DATA 0=MENU

SENSOR SETPOINTS LINEAR INPUT 12:00

#:01 Status:OFF Name:REFR LK ZN 01

Stay ON for:000 min Eng.Unit:PPM

Using Diff Of 01 00 00 00

0Of0000

Gain 250 Offset 00000 mv

ON: 0 Dly: 0000 OFF:0 Dly:0000

=PREV =NEXT ->=SET-DATA 0=MENU