Operation

Setting the Blade Depth

The TS 55 is equipped with a depth stop for setting the

depth of the blade during a plunge cut. Using the correct

blade depth improves cutting safety, cut quality, and motor

efficiency.

Instruction Manual 13

Effects of Too Shallow of a Setting

► Higher drag on the sawblade, requiring more power and

effort to complete the cut.

► Increased chance for kickback.

► Increased chipping and splintering on the underside of the

cut, especially with melamine and veneers.

► Increased burning of the cut, especially in certain

hardwoods like cherry and maple.

► With the exception of underside chipping, all of these

effects are greatest with finer-toothed blades.

Effects of Too Deep of a Setting

► Increased danger with more of the blade exposed below

the workpiece.

► Increased sawtooth marks in the cut.

► Increased top-side chipping and splintering, especially

without using the guide rail and splinter guards.

Blade Depth Recommendations

There are no set rules for

setting the depth of the

blade with respect to the

underside of the cut.

However, a common

industry guideline is to

have the gullets of the b

workpiece. This will therefore be used as a baseline to

describe optional depth settings.

► If a material is prone to burning in the cut, increase the

depth slightly. This includes ripping hardwoods such as

cherry and maple.

► Using a combination blade in solid wood may perform

better with a slightly deeper setting.

► Using a coarse blade in sheet materials may be improved

with a shallower cut.

► Cutting dense and/or hard materials may require a deeper

setting to decrease heat and load on the tool.

► Cutting fragile or shatter-prone materials such as plastics

or countertop laminates is best with a shallow setting (and

low speed).

► Cutting aluminum may be improved with a semi-shallow

setting, but not too shallow.

► When Used with the Multi-Function Table (MFT) you may

wish to keep the blade

depth shallower.

► Cutting non-fragile, non-

shattering plastics such as

polypropylene or solid-

surface countertops may

be improved with a deeper

cut.

► More aggressive blades,

such as the Panther

ripping blade, can be used

at a shallower setting.

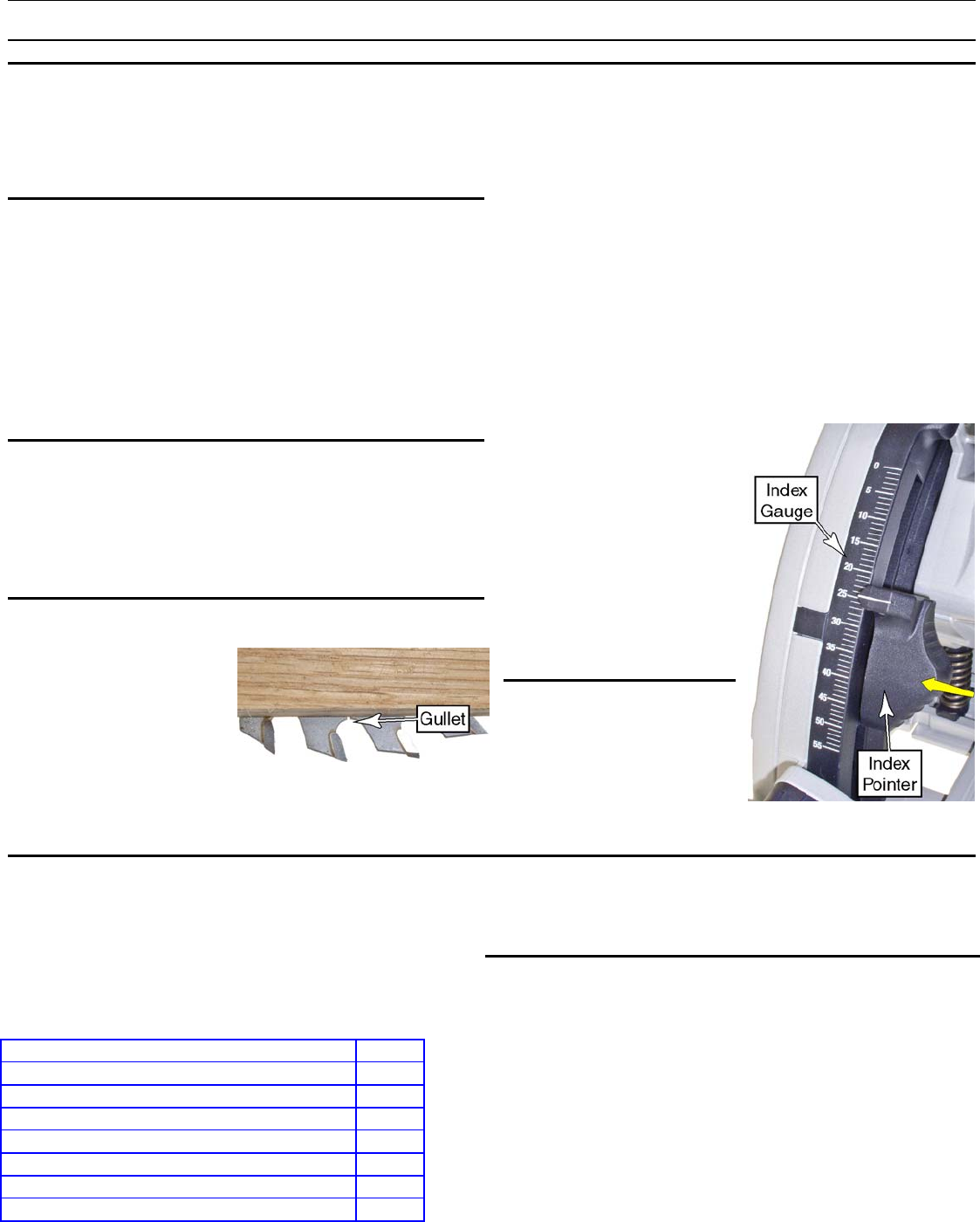

Using the Depth Stop

► Press in on the index

pointer and slide it up or

down to the desired

setting.

lade even with the underside of the

► When used with the guide r

depth to account for the guide rail thickness.

ail, add 5 mm to the desired

Setting the Motor Speed

The TS 55 has electronic speed control with soft-start

otor

al

e

Material Speed

circuitry. The electronic controller will maintain the m

speed even as the load changes. The speed control is

infinitely variable from 2000 to 5200 RPM. The optim

speed of the saw is predominately determined by the typ

of material being cut.

Soft wood products and veneer plywoods 6

Hardwood products 3-6

Plastic laminate countertops 6

Hard plastics 3-5

Soft plastics 1-4

Masonry and cementitious hardboard 1-3

Aluminum 4-6

Turn the speed control dial (shown on page 14) to the number

A Note About Speed Control

shown in the table to the left.

When you first turn on the saw and there is no load on the

he

motor controls the motor speed

sawblade, you may notice a slight “growling” sound from t

saw. This is normal, and is a result of the motor’s gears

reacting to the speed control.

The electronic controller in the

by turning it On and Off very rapidly. This form of speed

control is called "Pulse-Width Modulation" (PWM), and is

common in most power tools with a variable speed control.

When there is no load on the sawblade, the pulsations of the

motor cause the gears to rapidly engage and disengage (called

backlash), and this is the sound you are hearing.